Parallel-flow two-stage condensation heat pump water heater

A heat pump water heater and condenser technology, which is applied in the field of heat pump water heaters and downstream two-stage condensing heat pump water heaters, can solve the problems that the amount of hot water cannot meet water requirements, application site restrictions, and high costs, and achieves the reduction of water resources and thermal energy. The effect of waste, simple structure and high heating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

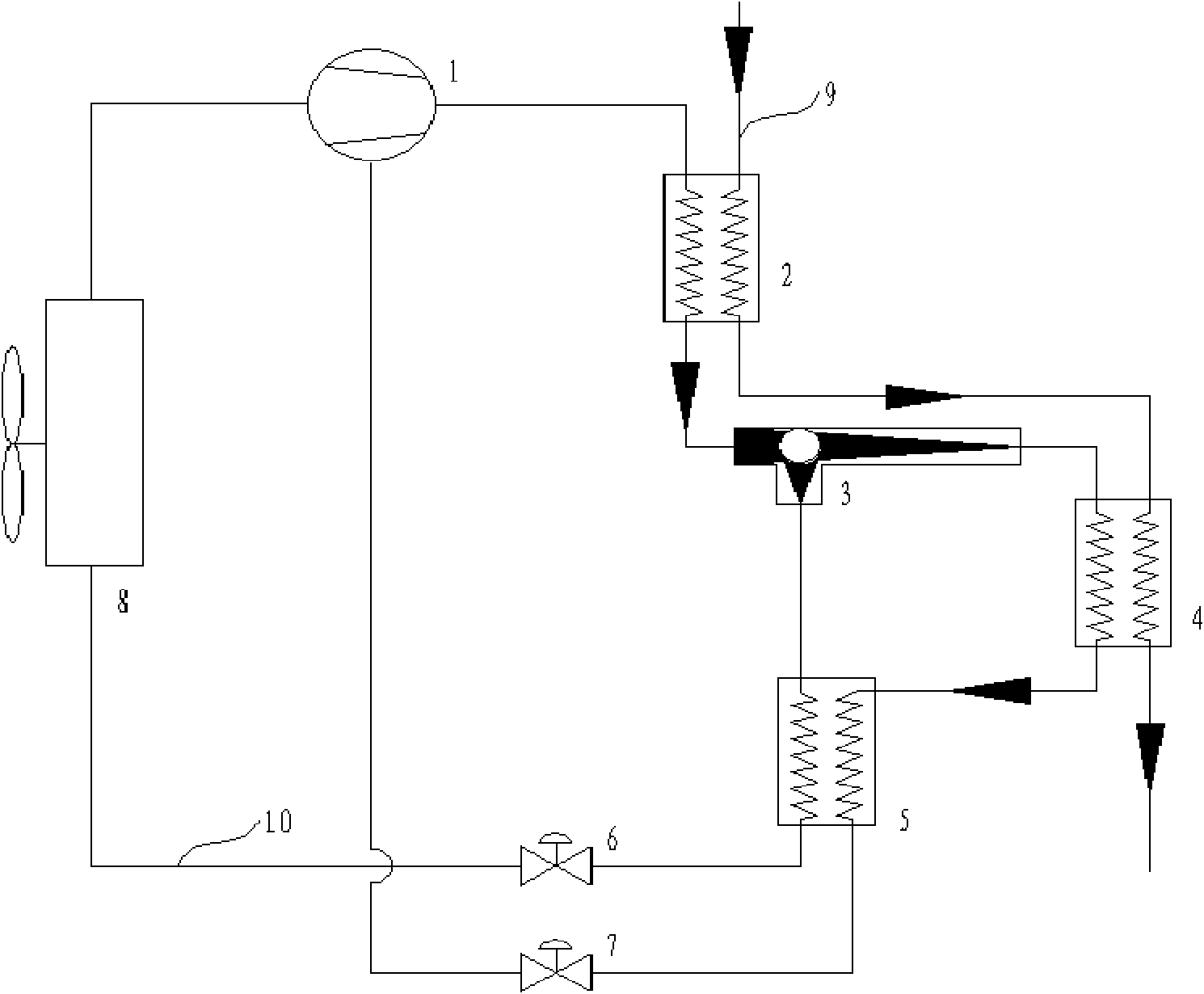

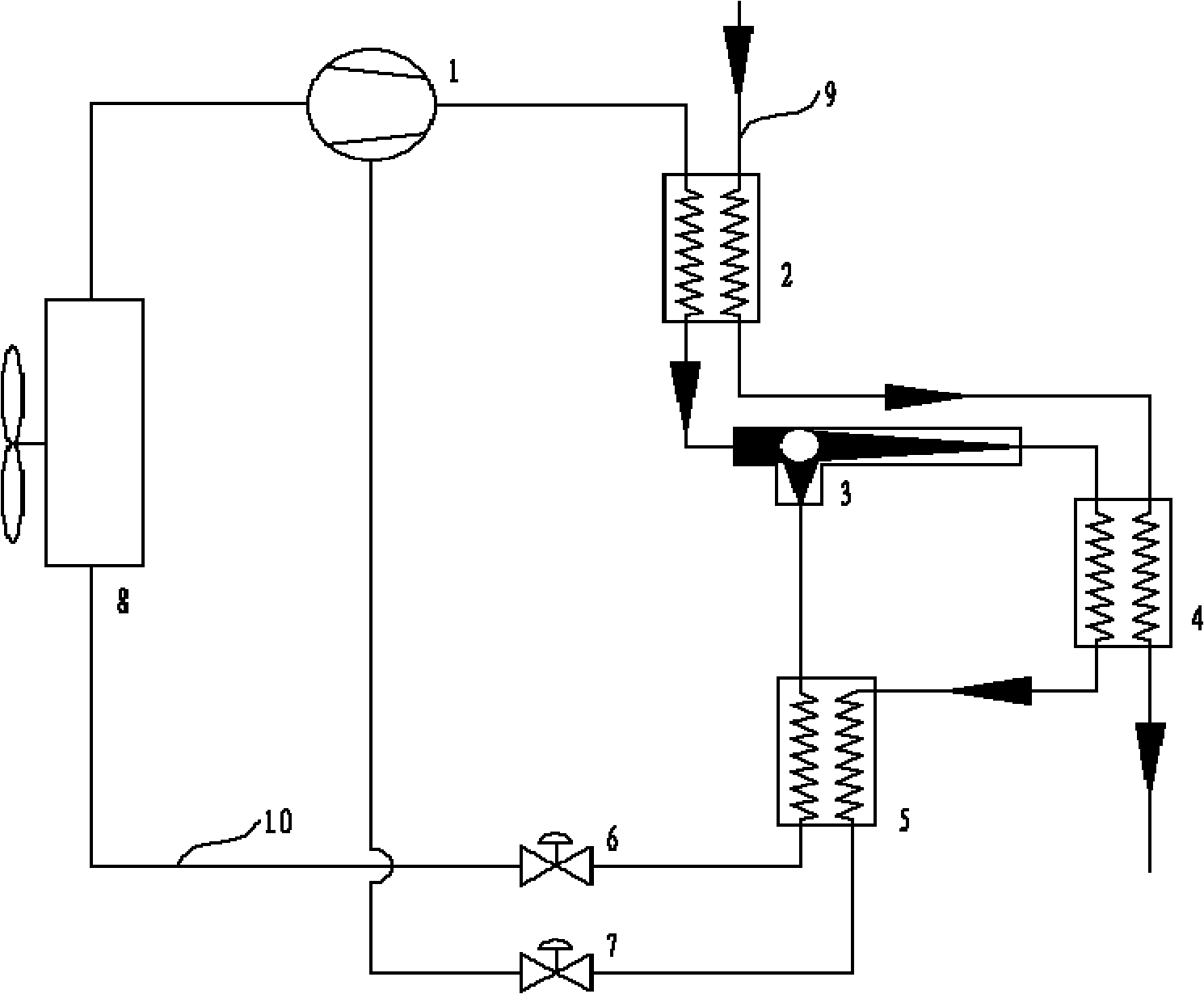

[0013] Such as figure 1 Shown is a schematic structural view of the downstream two-stage condensing heat pump water heater of the present invention. It includes a supplementary air enthalpy compressor 1, a primary condenser 2, a secondary condenser 4, a vortex tube refrigerator 3, an economizer 5, throttle valves 6, 7 and an evaporator 8; The exhaust port of the machine 1 is connected with the primary condenser 2, the air inlet of the vortex tube refrigerator 3, the low-temperature exhaust end of the vortex tube refrigerator 3, the economizer 5, the throttle valve 6, the evaporator 8 and the supplementary air enthalpy increase The suction port of the compressor 1 is connected in turn to form a fluorine side circulation flow path; the exhaust port of the air-supplementing enthalpy increasing compressor 1 is connected with the primary condenser 2, the intake end of the vortex tube refrigerator 3, and the vortex tube refrigerator The high-temperature exhaust end of 3, the econom...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com