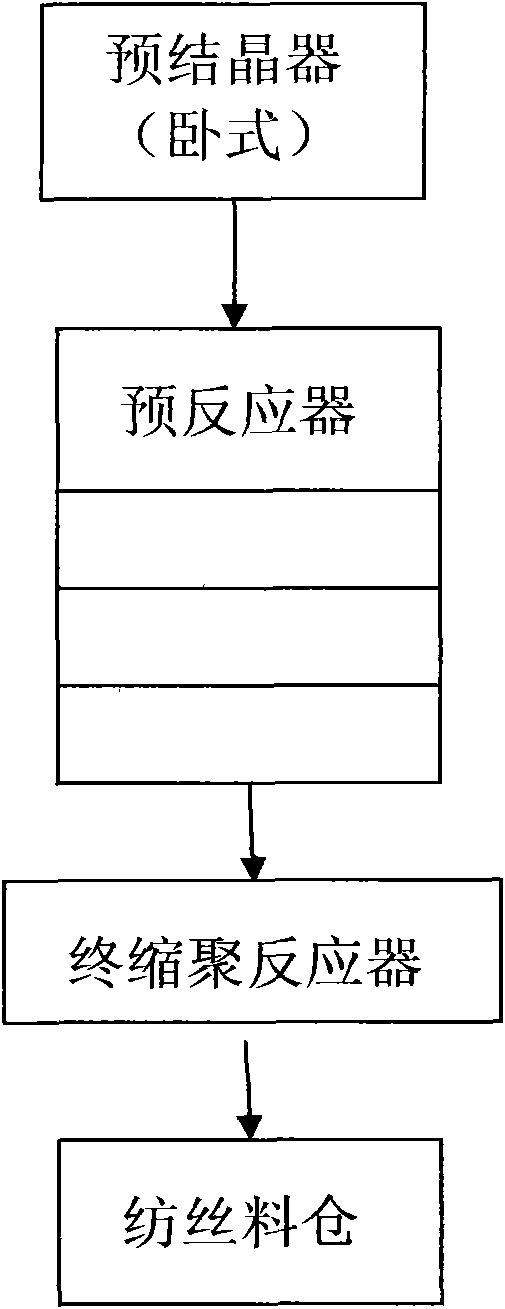

Production process of high-uniformity high-viscosity SSP (Solid State Polycondensation) polyester chip

A polyester chip and production process technology, applied in the field of chemical fiber production, can solve the problems that the SSP process cannot further improve the material flow speed, the uniformity of the chip viscosity is poor, and the production cycle is too long, so as to achieve rich process adjustment means and uniform chip crystallinity. , the effect of increasing the pre-reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

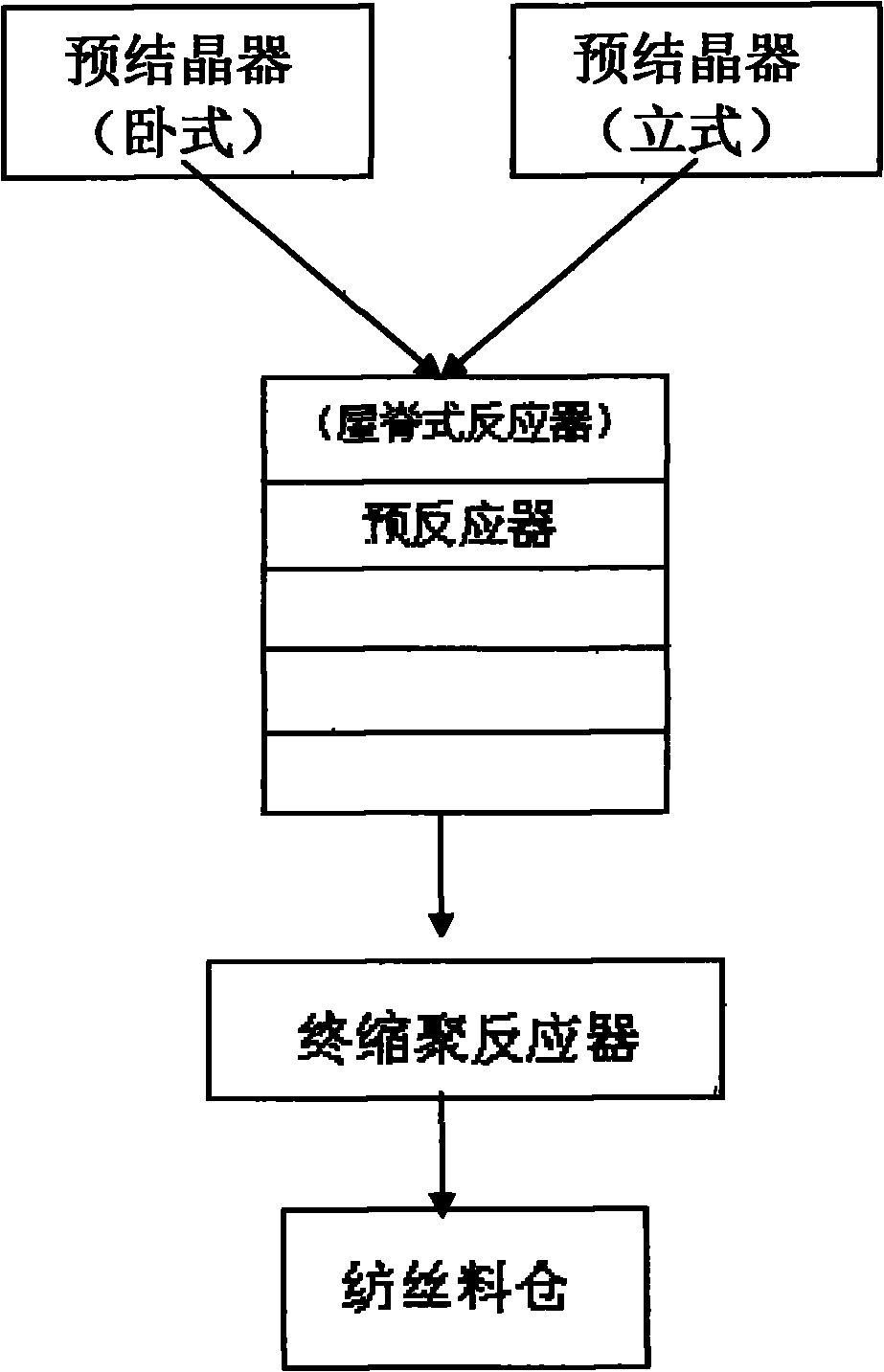

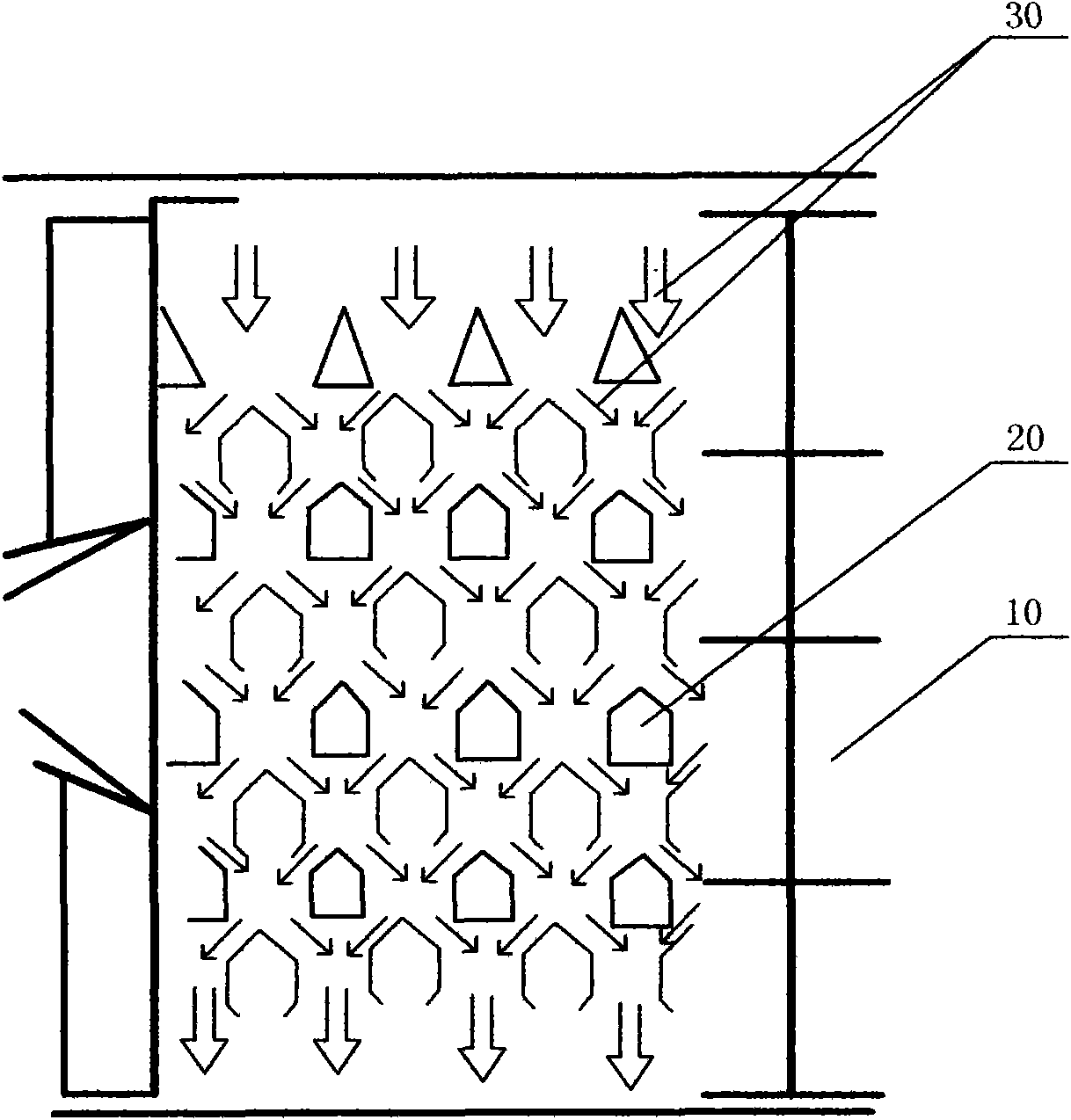

[0036] Embodiment 1: Production of high-uniformity and high-viscosity slices (viscosity at 1.07~1.09dl / g):

[0037]The low-viscosity chips with a viscosity of 0.67dl / g are sent from the polymer master sheet silo to two pre-crystallizers respectively. The temperature of the pre-crystallizers is controlled at 175-177°C, and the crystallization time is controlled at 12 minutes. Due to the addition of a pre-crystallizer, the input volume of the slices is greatly increased, and the crystallization time can be extended appropriately, which makes the crystallinity of the slices more uniform. The slices are transported to the top of the pre-reactor, where a roof-type reactor is installed on the top of the pre-reactor, that is, the original 4-stage pre-reactor is transformed into a 5-stage pre-reactor. When the slices pass through the uppermost ridge reactor, they will slide down from the gap of the ridge reactor and form a good and stable gradient. At this time, the slices push down a...

Embodiment 2

[0038] Embodiment 2: produce high uniformity low-viscosity chip (viscosity is at 0.96-0.98dl / g)

[0039] Low-viscosity slices with a viscosity of 0.67dl / g are sent to two pre-crystallizers from the polymer master chip silo. The temperature of the pre-crystallizers is controlled at 172-173°C, and the crystallization time is controlled at 15 minutes. Due to the addition of a crystallizer , the feeding amount of slices is greatly increased, and at the same time, the crystallization time can be extended appropriately to make the crystallinity of slices more uniform. The slices are transported to the top of the pre-reactor, where a roof-type reactor is installed on the top of the pre-reactor, that is, the original 3-stage pre-reactor is transformed into a 4-stage pre-reactor. When the slices pass through the uppermost ridge reactor, they will slide down from the gap of the ridge reactor and form a good and stable gradient. At this time, the slices push down and advance more evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com