Preparation method and reaction equipment of iodine pentafluoride

A technology of iodine pentafluoride and reaction equipment, applied in the direction of interhalogen compounds, etc., can solve the problems of low solubility, low reaction rate, low iodine solubility, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

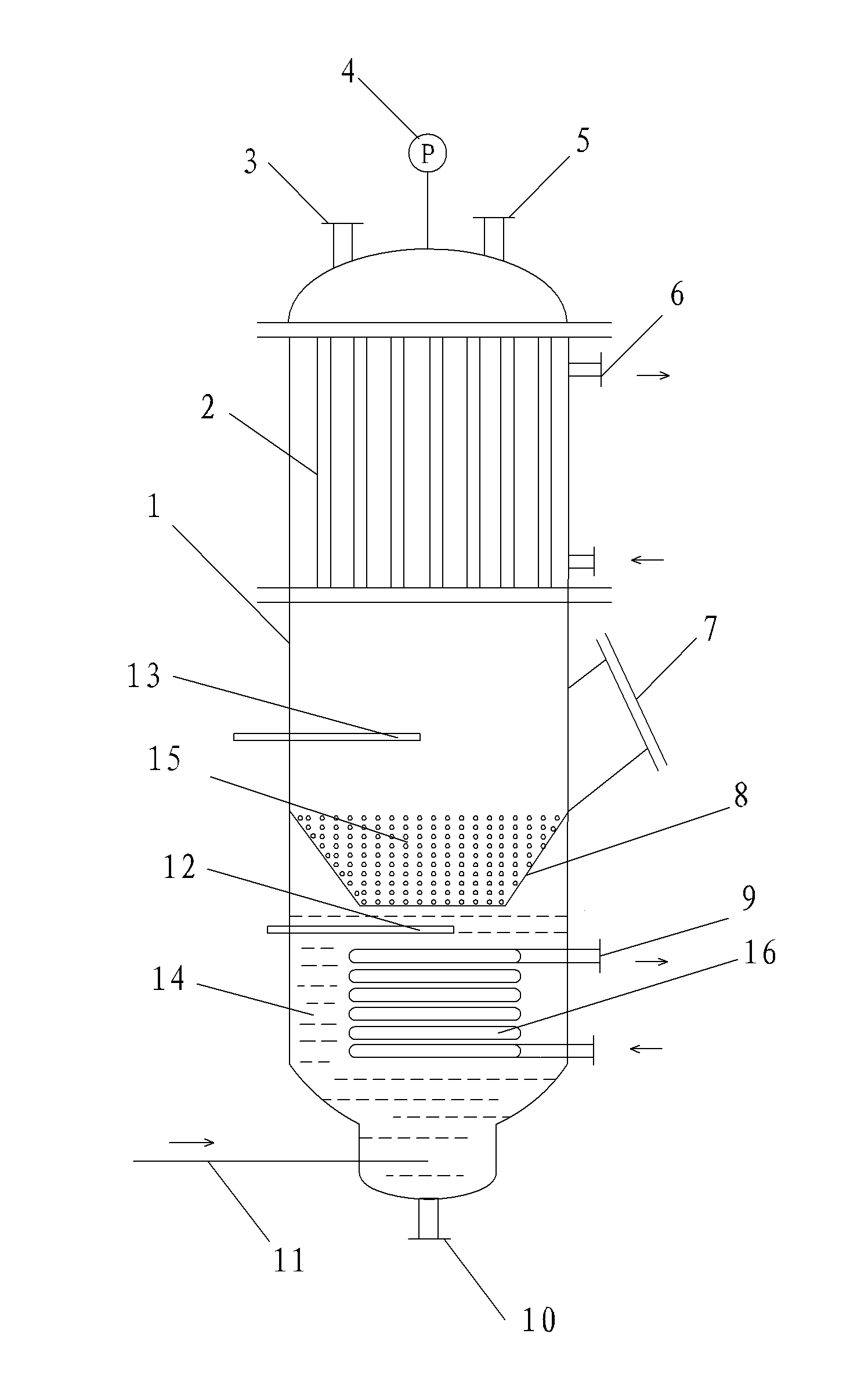

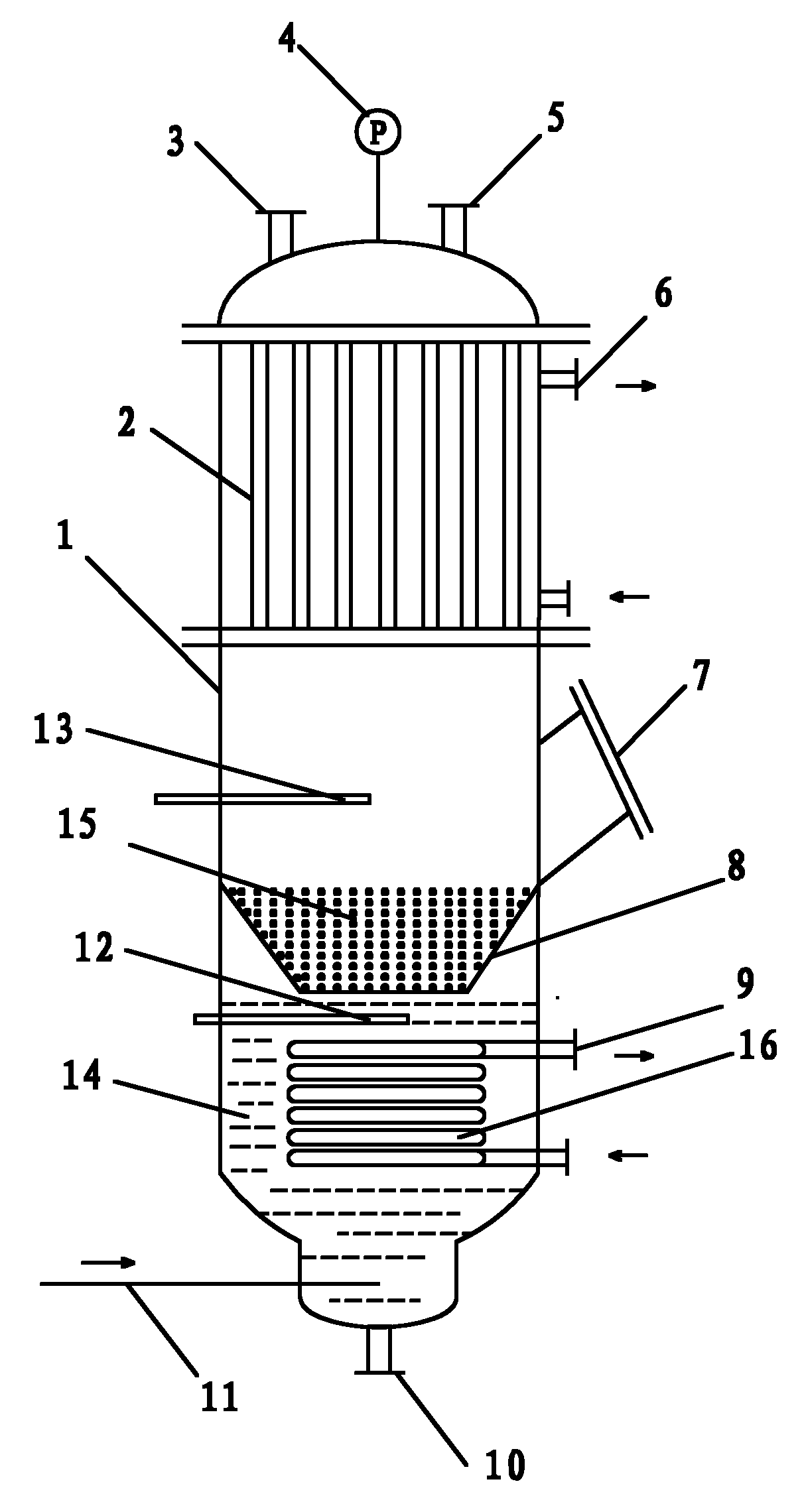

[0040] see figure 1 This embodiment provides a reaction device for preparing iodine pentafluoride. The reaction device includes a closed reactor 1, and the bottom of the reactor 1 is a space for accommodating the reaction solution 14. In this embodiment, the reaction solution 14 is iodine iodine pentafluoride solution, an iodine tray 8 is arranged above the space for accommodating the reaction solution 14, solid iodine 15 is placed on the iodine tray 8, and many small holes with a diameter of 5mm are arranged below the iodine tray 8, so that the bottom forms a similar The structure of the sieve plate, these small holes are iodine pentafluoride outlets flowing out to the space for containing the reaction solution 14, the solid iodine 15 does not directly contact the reaction solution 14, and the lower part of the space for containing the reaction solution 14 is provided with a fluorine gas inlet 11, Reactor 1 is provided with iodine addition port 7 and is used for adding the so...

Embodiment 2

[0046] With reference to the equipment and steps described in Example 1, first purify reactor 1, get 100 kg of iodine pentafluoride liquid and add it to the reactor, then get 100 kg of iodine (purity 99.5%) and add it to the reactor, and blow the reactor repeatedly. Pure nitrogen, to replace the air introduced by iodine addition in the reactor, pass cooling water to pass fluorine gas, at this time, the temperature in the reactor begins to rise, and the pressure increases slowly. When the pressure in the reactor is higher than 0.035MPa, open the reactor to vent The valve discharges impurity gas, reduces the internal pressure of the reactor to normal pressure, and then continues the reaction.

[0047] During the reaction process, the temperature was kept at 65-80°C. When the temperature of the reactor tended to drop significantly, the input of fluorine gas was reduced to check the termination of the reaction. The increase of iodine pentafluoride was 173kg, and the product yield w...

Embodiment 3

[0049] With reference to the equipment and steps described in Example 1, first purify the reactor, get 100 kg of iodine pentafluoride liquid and add it to the reactor, then get 300 kg of iodine (purity 99.5%) and add it to the reactor; Blow high-purity nitrogen to replace the air introduced by iodine addition in the reactor, pass cooling water; pass fluorine gas, at this time, the temperature in the reactor begins to rise, and the pressure increases slowly. When the pressure in the reactor is higher than 0.035MPa, open The reactor vent valve discharges impurity gas, reduces the internal pressure of the reactor to normal pressure, and then continues the reaction.

[0050] During the reaction process, the temperature was maintained at 65-80°C. When the temperature of the reactor tended to drop significantly, the input of fluorine gas was reduced to check the termination of the reaction. The increase of iodine pentafluoride was 520kg, and the product yield was 99.1%.

[0051] As ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com