Method for preparing gypsum building block with titanium gypsum

A technology of gypsum block and titanium gypsum, applied in the field of building materials, can solve the problems of stacking and pollution of titanium gypsum

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

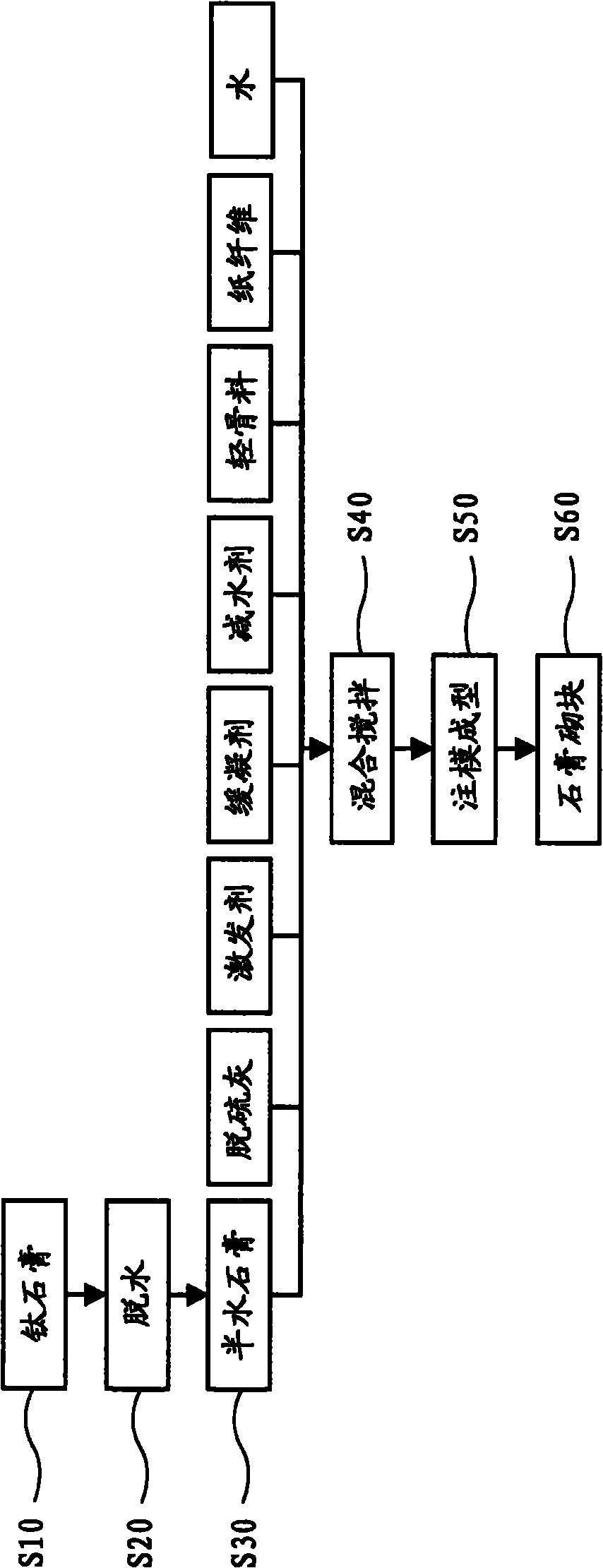

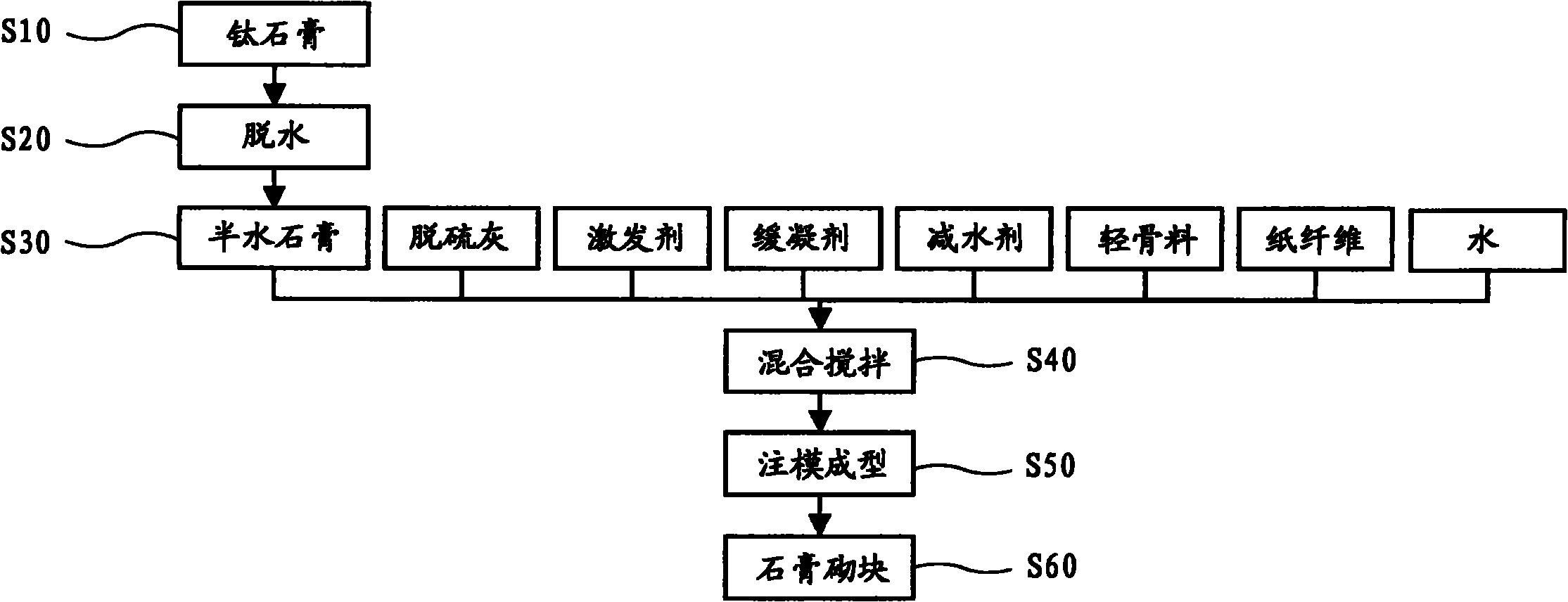

Method used

Image

Examples

Embodiment 1

[0025] The titanium gypsum is crushed to a particle size of 80 μm or less, and then dried at 180°C to obtain hemihydrate gypsum. By weight percentage, 30% titanium gypsum powder (dehydrated hemihydrate gypsum), 30% semi-dry desulfurization Ash, 35% lightweight aggregate, 2% gypsum activator, 2% retarder, and 1% water reducer are mixed evenly, wherein the gypsum activator is green vanadium, the retarder is citric acid, and the water reducer It is melamine, and the lightweight aggregate is water-quenched blast furnace slag; add 37% water by weight to the mixed material, mix and stir evenly, pour it into the mold, and vibrate to shape; after 2 hours of natural curing, the slurry hardens, remove the mold and dry it Then get the gypsum block. The gypsum block was tested, and the flexural strength of the gypsum block was 2.9MPa, the compressive strength was 8.5MPa, and the bulk density was 1.1g / cm 3 , The softening coefficient is 0.65, and all the above indicators have reached the ...

Embodiment 2

[0027] Titanium gypsum is crushed to a particle size below 80 μm, and then dried at 200° C. to obtain hemihydrate gypsum. By weight percentage, 60% titanium gypsum powder (dehydrated hemihydrate gypsum), 25% lightweight aggregate, 3% gypsum activator, 1% retarder, 1% water reducer and 10% paper fiber are mixed evenly, wherein the gypsum activator is sodium sulfate, the retarder is citric acid, and the water reducer is melamine formaldehyde Resin, lightweight aggregate is light ceramsite; add 38% water by weight to the mixed material, mix and stir evenly, pour into the mold, and vibrate to shape; after 2 hours of natural curing, the slurry hardens, remove the mold and dry Then get the gypsum block. The gypsum block was tested, and the flexural strength of the gypsum block was 2.5MPa, the compressive strength was 6.8MPa, and the bulk density was 0.95g / cm 3 , The softening coefficient is 0.57, and all the above indicators have reached the national building materials industry sta...

Embodiment 3

[0029] The titanium gypsum is crushed to a particle size of 80 μm or less, and then dried at 200°C to obtain hemihydrate gypsum. By weight percentage, 60% titanium gypsum powder (dehydrated hemihydrate gypsum), 15% semi-dry desulfurization Ash, 15% lightweight aggregate, 3% gypsum activator, 1% retarder, 1% water reducer and 5% paper fiber are mixed evenly, wherein the gypsum activator is green vanadium, and the retarder is Citric acid, water reducing agent is melamine, light aggregate is floating beads; add water with a weight percentage of 39% to the mixed material, mix and stir evenly, pour it into the mold, and vibrate to form; after 2 hours of natural, the slurry hardens, disassemble After the mold is dried, a gypsum block is obtained. The gypsum block was tested, and the flexural strength of the gypsum block was 5.0MPa, the compressive strength was 1.8MPa, and the bulk density was 0.85g / cm 3 , The softening coefficient is 0.45, and all the above indicators have reached ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com