Method for machining spatial hole by using large ellipsoid on numerical control boring-milling machine

An ellipsoid and boring and milling machine technology, which is applied in the field of mechanical processing, can solve the problems of inability to process and measure difficulties with CNC gantry milling machines, and achieve the effects of improving programming accuracy, reducing processing failures, and safe and reliable processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

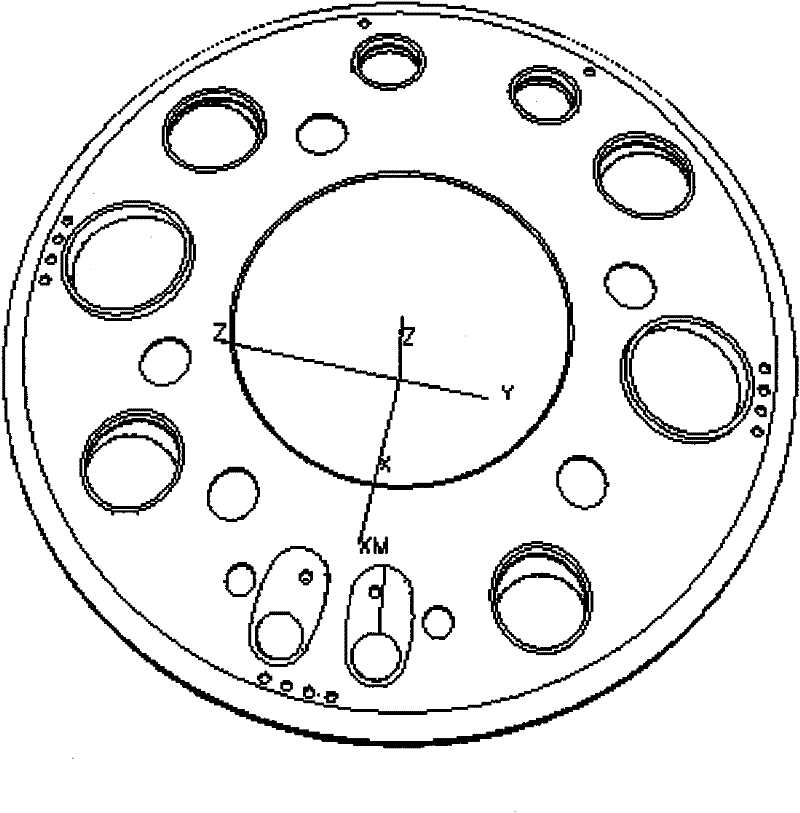

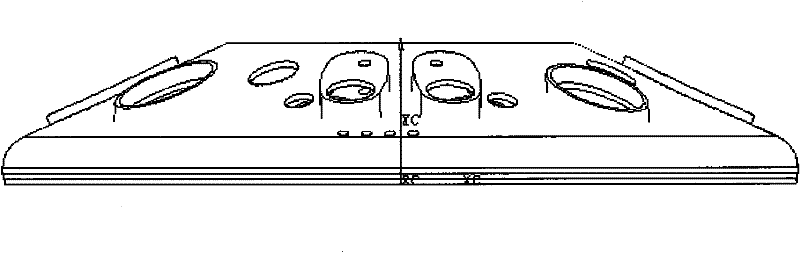

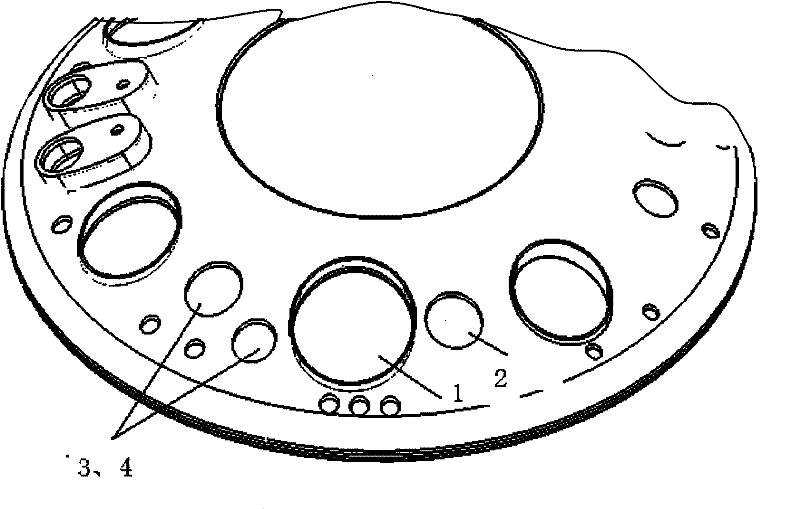

[0033] The present invention will be further described below with reference to the embodiments given in the accompanying drawings. The embodiment is an example of processing an ellipsoid of a large cylindrical body in a petrochemical facility. The diameter of the ellipsoid of the large cylinder is 8000mm, on which there are 34 spatial holes of different sizes. First, use siemens nx6CAD\CAM software to analyze the shape and spatial position of the workpiece, determine the number of clampings required to process the workpiece with the CNC boring and milling machine, and the range of the holes processed by each clamping and the clamping reference; then formulate the CNC machining program of the space hole; Use the VERICUT CNC machine tool simulation software to verify the CNC machining program; clamp and align the parts according to the CNC requirements, and reserve the machining space holes according to the CNC machining program; use three coordinates to detect the spatial posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com