Electroplastic self-piercing riveting device

A self-piercing riveting and electroplastic technology, applied in the field of automobile manufacturing, can solve the problems of reducing the strength of rivets, the rigidity of equipment punching riveting ability, reducing the plastic deformation resistance of riveted advanced high-strength steel, and the radial cracks of joints. Plastic deformation capacity, improved connection quality, strong mechanical interlocking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

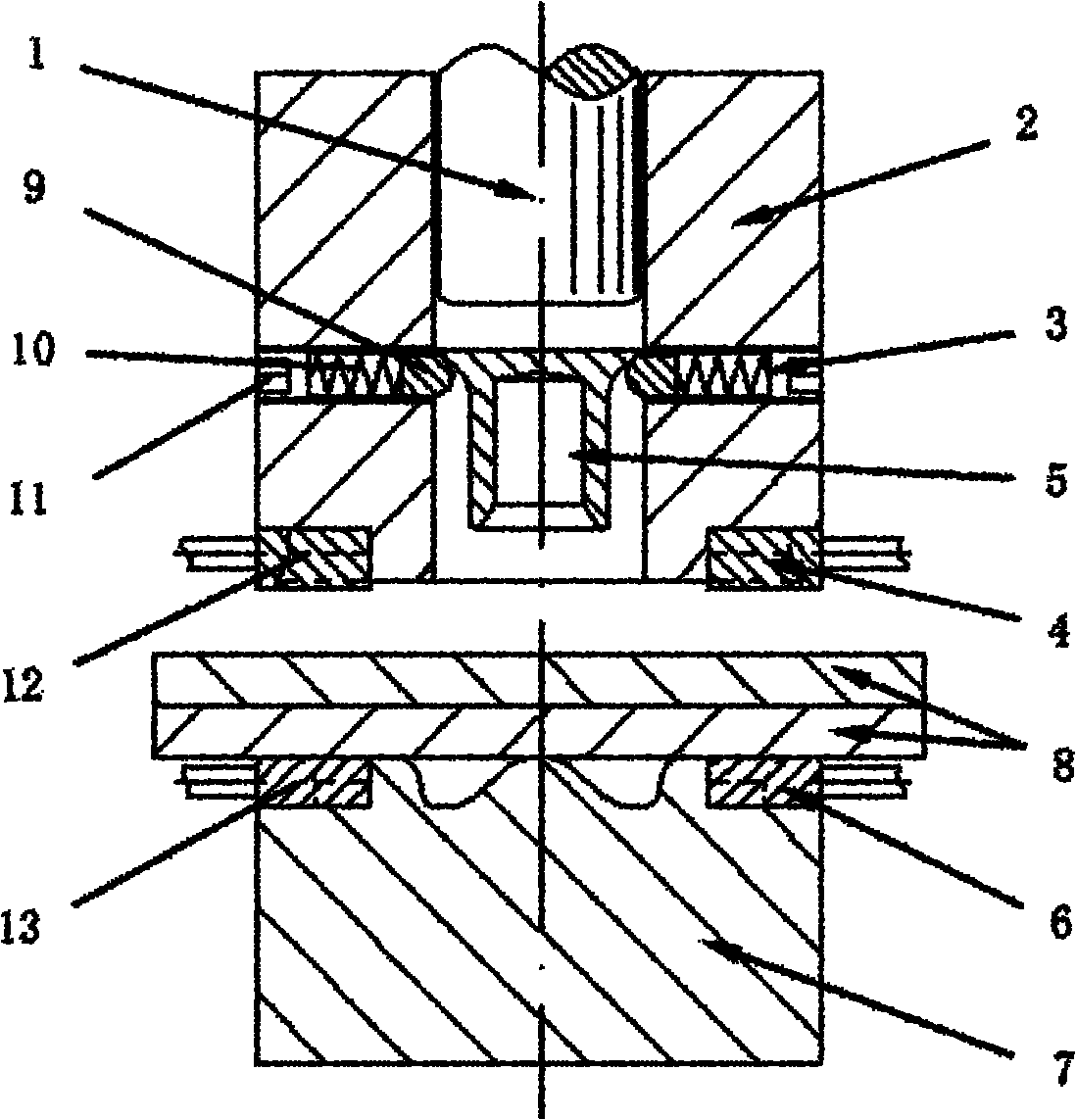

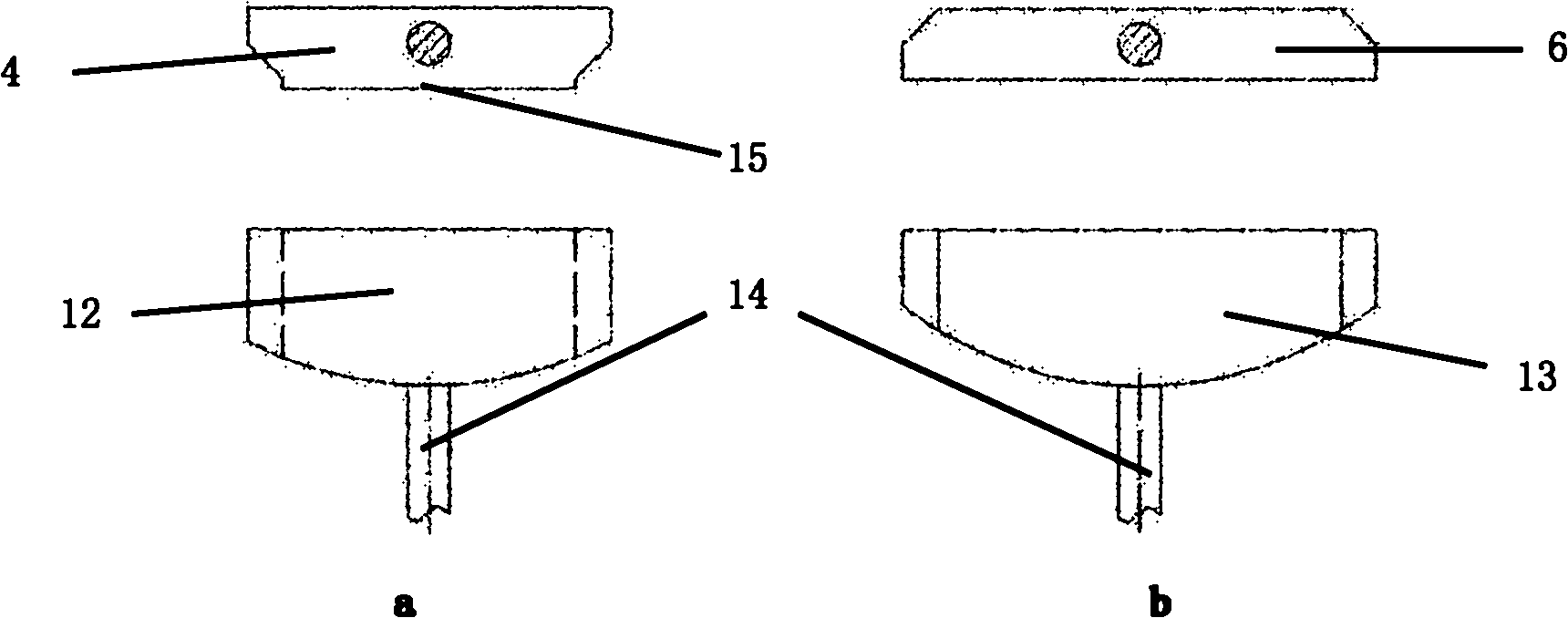

[0031] like figure 1 As shown, this embodiment includes: driving rod 1, blank holder ring 2, several spring bead positioning mechanisms 3, upper brush 4, semi-hollow rivet 5, lower brush 6 and die 7, wherein: blank holder ring 2 , The plates to be connected 8 and the die 7 are arranged sequentially from top to bottom, the driving rod 1 is sleeved in the blank holder 2, and several spring bead positioning mechanisms 3 are distributed horizontally in the radial direction in the blank holder 2, semi-hollow Rivet 5 is vertically placed in blankholder 2 and contacts with spring bead positioning mechanism 3, and drive rod 1, blankholder 2, semi-hollow rivet 5 and die 7 are coaxially arranged.

[0032] The driving rod 1 is made of insulating material or high-strength steel coated with insulating paint, and the diameter of the rod body is 7.8mm.

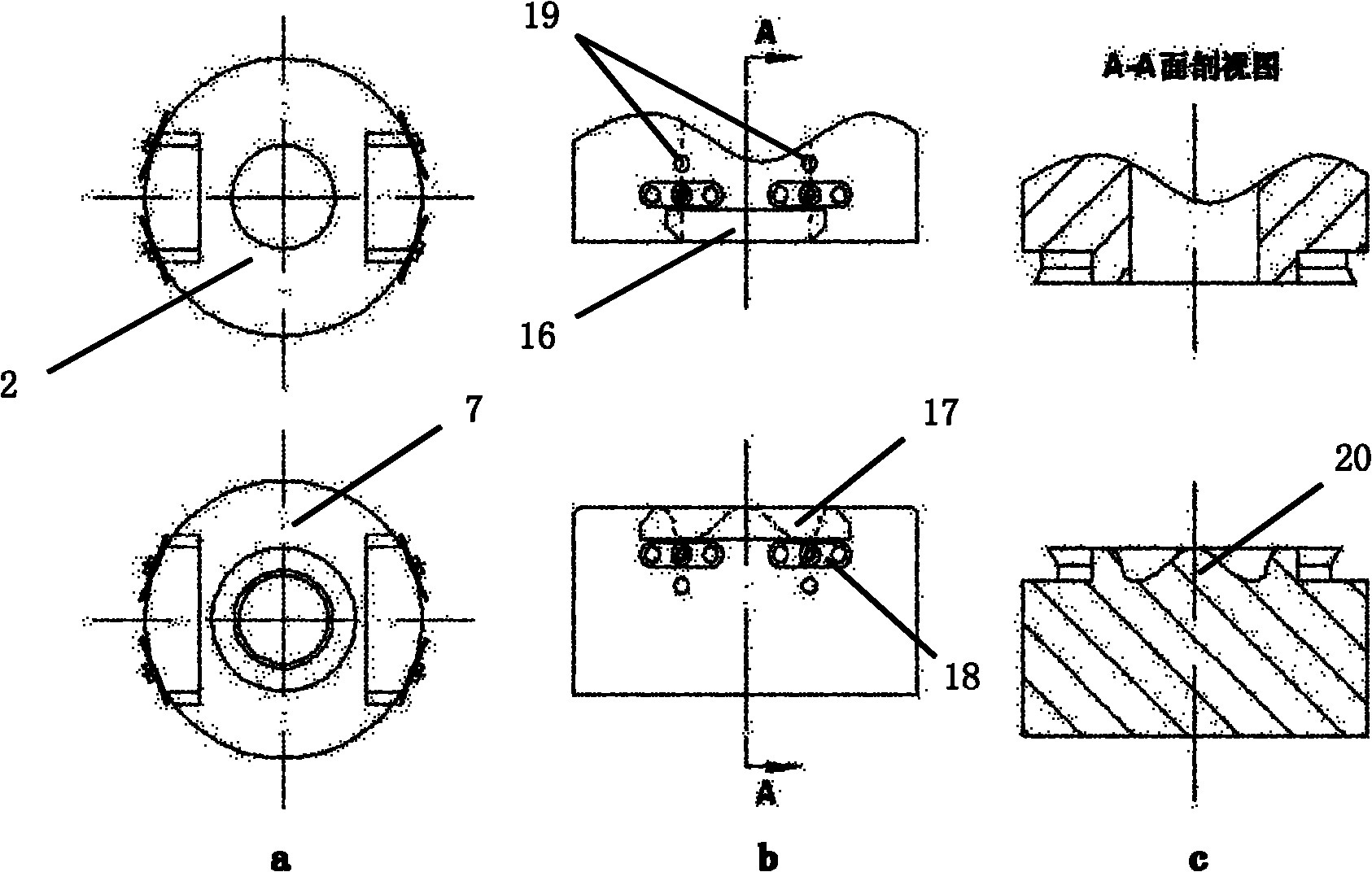

[0033] The inner diameter of the blank holder 2 is 8.2 mm, the outer diameter is 22 mm, and there are four threaded holes of φ2.4 evenly d...

Embodiment 2

[0052] The plates 8 to be connected in this embodiment are: aluminum alloy AA6061-T6+cast aluminum A356-T6, and the thickness of the plates matches: 1mm+3mm.

[0053] The semi-hollow rivet 5 in this embodiment adopts a traditional self-piercing riveting countersunk rivet with a head diameter of 7.8 mm, a leg outer diameter of 5.3 mm, and a rivet length of 7 mm. The material is boron-treated medium carbon steel.

[0054] Process parameters: the impact speed of the driving rod 1 is 100mm / in, the impact stroke is 7mm, the current of the upper brush 4 is 1800A, and the current of the lower brush 6 is 2400A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com