Method for treating organic matters in large-capacity industrial waste gas

A technology for industrial waste gas and organic matter, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, which can solve problems such as increasing the processing load of organic waste gas treatment systems, increasing system construction costs, and increasing the number of auxiliary equipment, etc., to reduce system waste. The failure rate, saving transformation investment, and realizing the effect of continuous adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

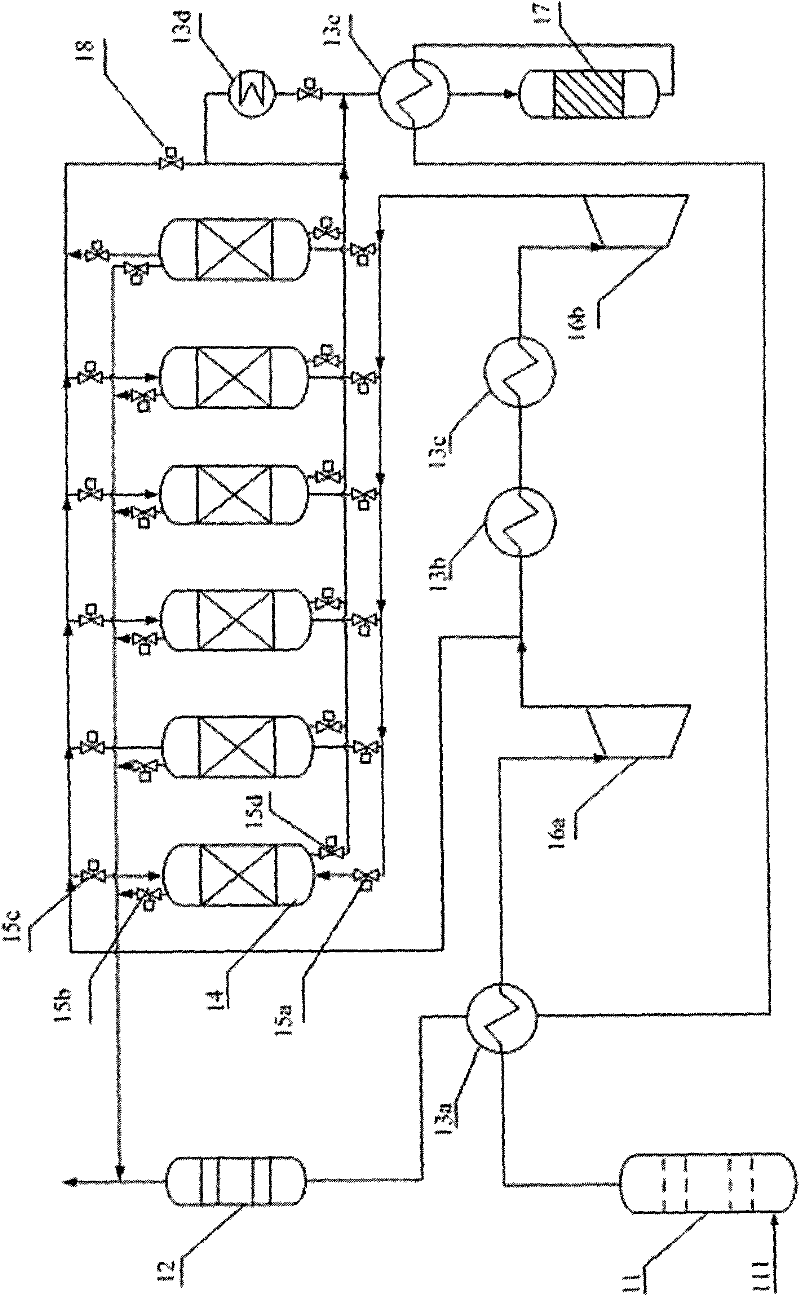

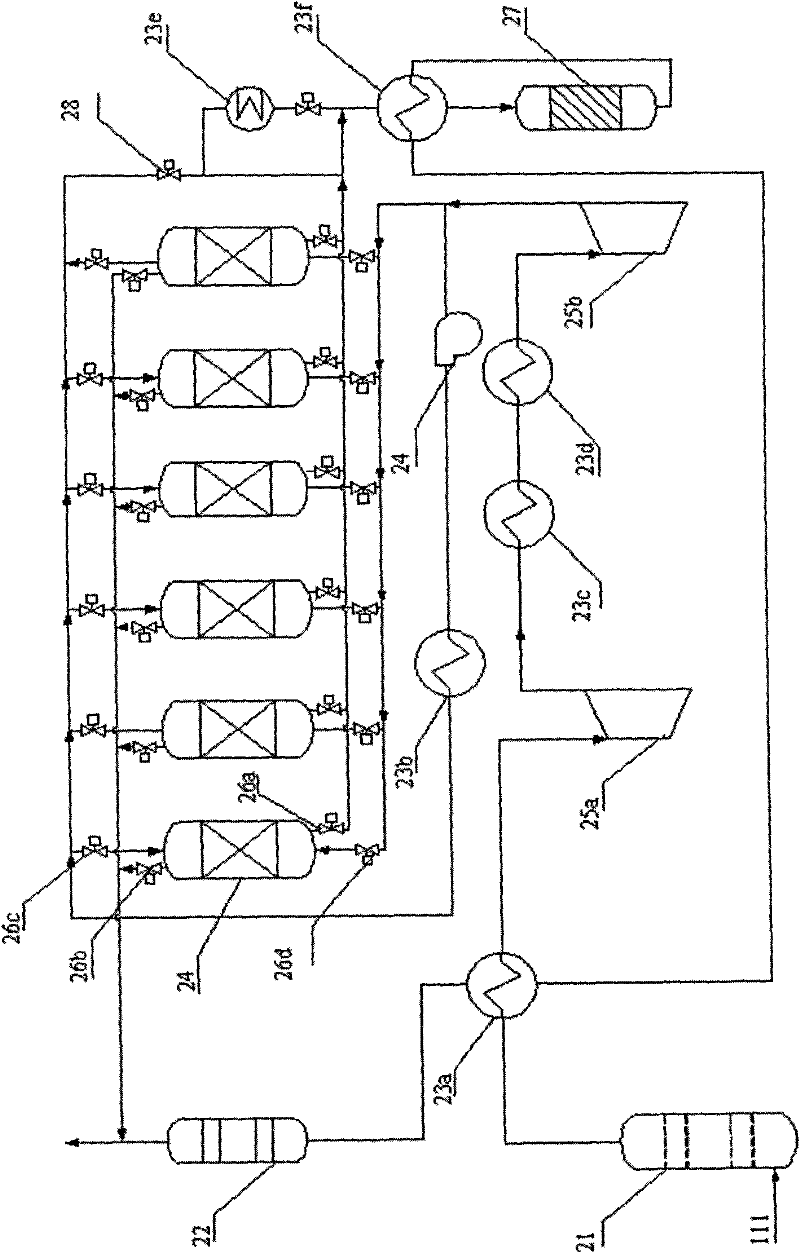

[0029] The invention will be described in detail below in conjunction with the drawings and examples, which do not limit the invention in any way. In this example, the purification treatment of oxidized industrial waste gas in the production of terephthalic acid (PTA) is taken as an example to illustrate. Its process is as follows figure 1 with figure 2 shown.

[0030] The main components of PTA oxidation waste gas are nitrogen, oxygen, carbon dioxide, carbon monoxide, methyl acetate, benzene, p-xylene, toluene, methyl bromide, acetic acid, and water. Usually, the operating pressure of the production system is about 10atm, and the temperature is about 110°C. . The concentrations of benzene, p-xylene, toluene and methyl bromide in the waste gas are respectively 20-100 mg / m 3 , are toxic carcinogens, easy to cause great harm to the human body, and need to be dealt with.

[0031] Such as figure 1 As shown, first, the waste gas 111 produced by oxidation is washed 11 by a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com