Filtering material and application thereof

A filter material and fabric technology, applied in the direction of filtration separation, separation/purification of carboxylic acid compounds, carboxylate preparation, etc., can solve the problems of short material replacement cycle, small flux, low elongation, etc., and achieve mechanical properties Superior, good filtering effect, high breaking strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

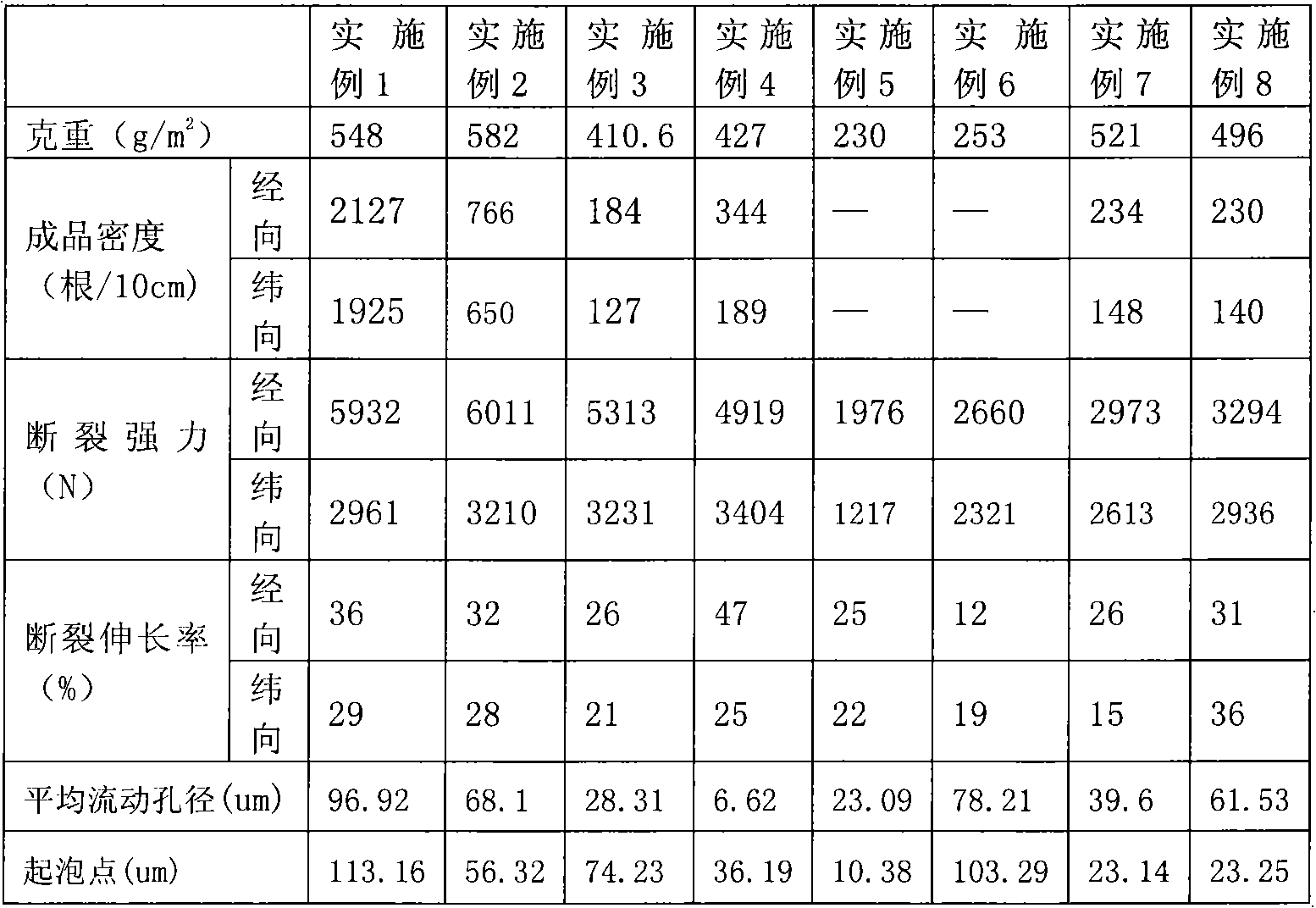

[0035] The PPS monofilament (manufactured by Toray Co., Ltd.) with an average fiber diameter of 36 μm is warped, and the warp density is 2235 / 10cm, the weft density is 1948 / 10cm, and the organization is 1 / 3 twill weaving, and the warp density is 2127 The PPS monofilament twill fabric with threads / 10cm and weft density of 1925 threads / 10cm can be used as a filter material for liquid filtration in the production process of PTA or TPA. The characteristics of this filter material were evaluated and are shown in Table 1.

Embodiment 2

[0037] The PPS monofilament (manufactured by Toray Co., Ltd.) with an average fiber diameter of 120 μm is warped, and the warp density is 800 / 10cm, the weft density is 660 / 10cm, and the organization is 1 / 3 twill weaving, and the warp density is 766 The PPS monofilament twill fabric with threads / 10cm and weft density of 650 threads / 10cm can be used as a filter material for liquid filtration in the production process of PTA or TPA. The characteristics of this filter material were evaluated and are shown in Table 1.

Embodiment 3

[0039]Warp the PPS filaments (manufactured by Toray Co., Ltd.) with a total fiber fineness of 220dtex*6 and a single filament diameter of 7 μm. The warp density is 173 / 10cm, the weft density is 118 / 10cm, and the weave is 1 / 1 Weaving the plain weave to obtain a PPS filament plain weave fabric with a warp density of 184 / 10cm and a weft density of 127 / 10cm. The resulting fabric can be used as a filter material for liquid filtration in the production process of PTA or TPA. The characteristics of this filter material were evaluated and are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com