Method of producing coral powder

A coral powder and coral technology, applied in the field of coral powder preparation, can solve the problems of weathered corals, such as the ability to absorb hydrogen is not high, hydrogen cannot be confirmed, and the electrode is not clear, so as to improve the antioxidant capacity, prevent tissue damage, Improve the effect of plant cultivation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Wash 1 kg of dry weathered coral with tap water and dry it in the sun, then crush the dried weathered coral into a size of approximately 5×5mm by a pulverizer, and heat-treat the crushed coral at 300°C for 4 hours, so that the inside of the coral The organic matter is dissipated, and then adjusted so that the conductivity of the sodium chloride aqueous solution reaches 500μS / cm, and the coral is placed in the cathode-side electrolyzed water (alkaline ionized water) generated by applying a direct current of 1L4A per minute for electrolysis. Dried after soaking for 5 hours. After drying, hydrogen gas is adsorbed (attached) to the coral pieces in an airtight container, and crushed to about 100 mesh with a pulverizer.

[0049] The coral powder without the above-mentioned treatment was dissolved in pure water as a control group, and the electrical conductivity and redox potential were compared.

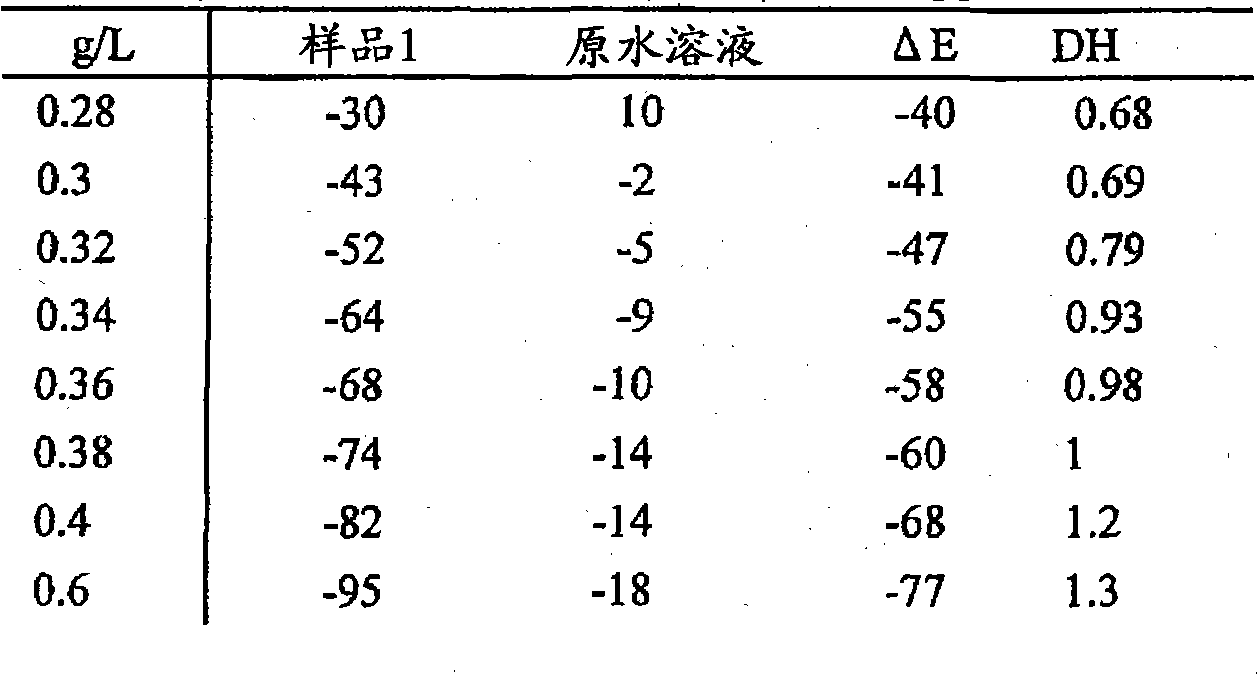

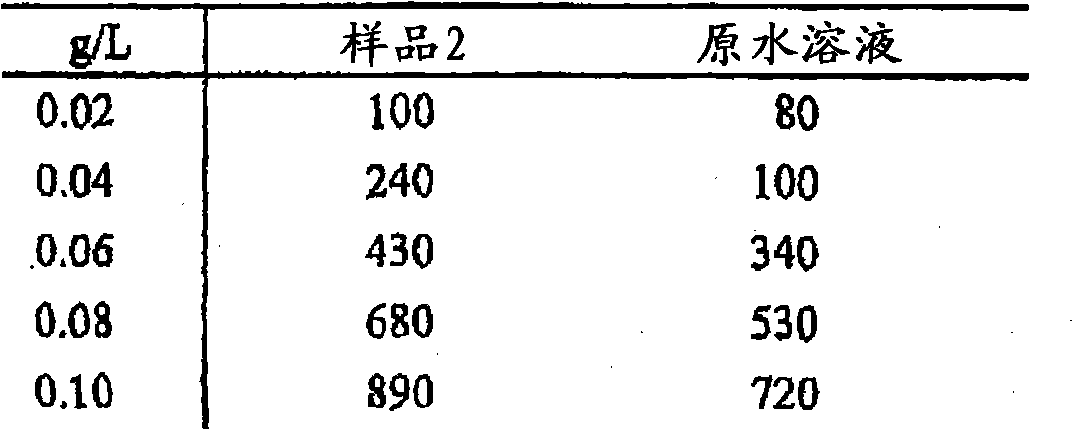

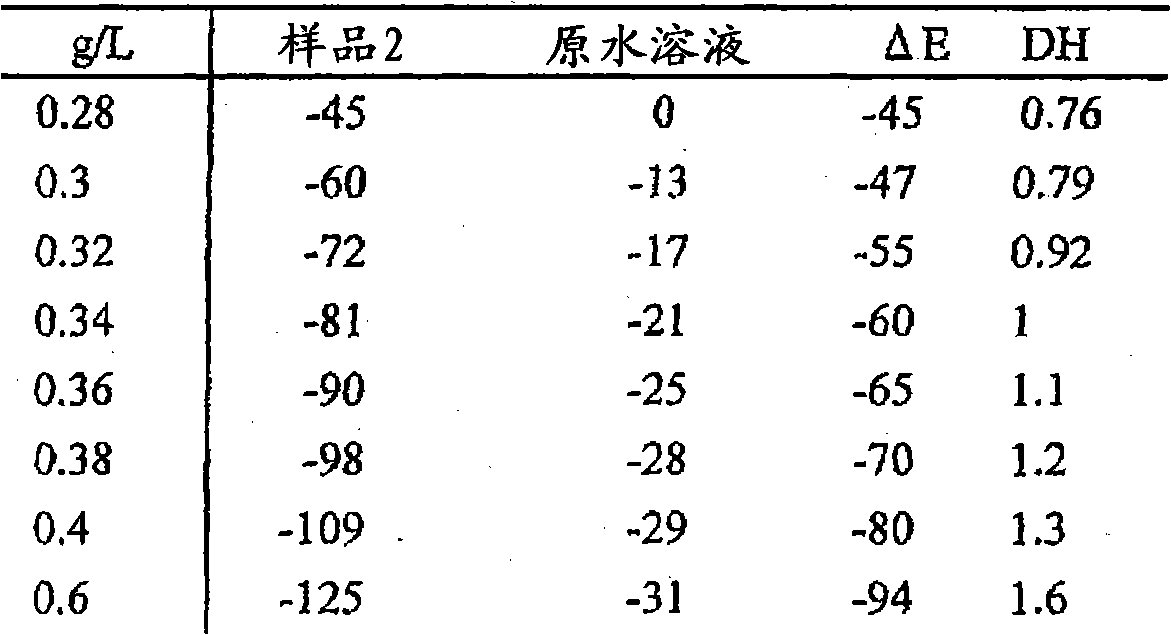

[0050] Dissolve 0.02g, 0.04g, 0.06g, 0.08g, 0.1g of the coral fine powder of s...

Embodiment 2

[0059] Wash 1 kg of dry weathered coral with tap water and dry it in the sun, then crush the dried weathered coral into a size of approximately 5×5mm by a pulverizer, adjust the conductivity of potassium chloride aqueous solution to 500 μS / cm, and apply The crushed coral was immersed in the cathode-side electrolyzed water (alkaline ionized water) generated by electrolysis at 1L7A of direct current per minute for 5 hours, and then the crushed coral was heat-treated at 800°C for 1 hour, so that the inside of the coral The organic matter escapes and dries up. The dried pulverized coral was allowed to absorb hydrogen in an airtight container, and then micronized to about 100 mesh with a pulverizer to obtain sample 3.

[0060] The electrical conductivity and oxidation-reduction potential were compared between the case of dissolving the coral powder of sample 3 containing hydrogen in pure water and the case of the original aqueous solution not containing hydrogen.

[0061] The cora...

Embodiment 3

[0070] Wash 1kg of dry weathered coral with tap water and dry it in the sun, then crush the dried weathered coral into a size of approximately 5×5mm by a pulverizer, and heat the crushed coral at 500°C for 3 hours, so that the coral in the coral Dissipate organic matter, then adjust the conductivity of sodium bicarbonate aqueous solution to 500μS / cm, and immerse the crushed coral in cathode-side electrolyzed water (alkaline ionized water) generated by electrolysis with a direct current of 1L7A per minute Dry after 5 hours. The dried pulverized coral and zeolite fine powder were mixed at a ratio of 1:1, and hydrogen gas was adsorbed or attached to the mixed material in a closed container, and then pulverized to about 100 mesh by a pulverizer to obtain sample 4.

[0071] The conductivity and oxidation-reduction potential of sample 4 obtained by dissolving a mixture of coral powder and zeolite containing hydrogen in pure water were compared with those of the original solution not...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com