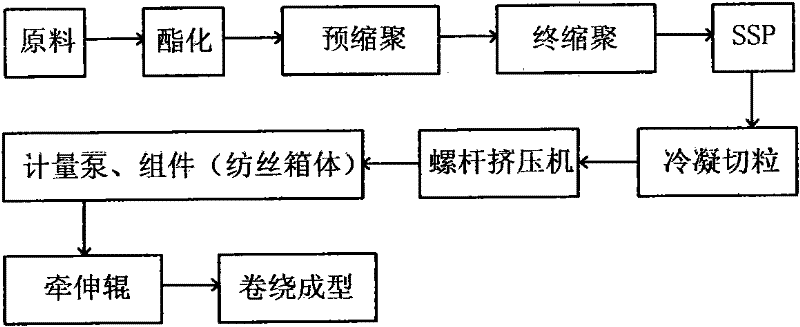

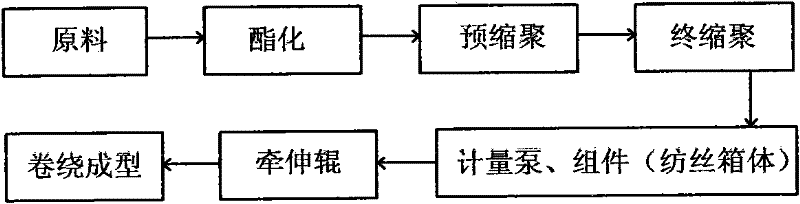

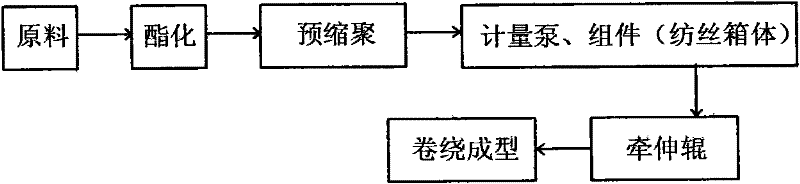

Technology for producing direct spinning terylene industrial filaments after liquid state polycondensation of prepolymer

A liquid phase viscosifying and production process technology, applied in the field of spinning, can solve the problems of unstable polyester industrial yarn product quality, high production cost pressure, complex procedures, etc. shortening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0062] Embodiment 1: Production of high-strength polyester industrial yarn

[0063] 1. Esterification: Put ethylene glycol and phthalic acid in a molar ratio of 1 to 1.3, put in catalyst, trimethyl phosphate, and electrostatic adsorbent to mix into a slurry, and carry out esterification reaction at a temperature of 230 to 260°C to obtain Ethylene terephthalate melt BHET;

[0064] 2. Pre-condensation: Carry out pre-condensation reaction at a temperature of 230-290 ° C and a pressure of 50-1000 Pa for 1.5-2 hours, and discharge when the melt viscosity is 0.3-0.4 dl / g measured by a viscometer;

[0065] 3. Liquid phase thickening: such as Figure 4 As shown, the melt prepared by precondensation is discharged through the melt jacket three-way valve 1, the prepolymer booster pump 2 (commonly known as the gear pump) is pressurized, and the melt three-way valve 3 is collected, and then passed through the double-connected Type melt filter 4 (double parallel connection can be switched...

Embodiment 2

[0067] Embodiment 2: Production of low-shrinkage polyester industrial filament

[0068] 1. Esterification: Put ethylene glycol and phthalic acid in a molar ratio of 1 to 1.3, put in catalyst, trimethyl phosphate, and electrostatic adsorbent to mix into a slurry, and carry out esterification reaction at a temperature of 230 to 260°C to obtain Ethylene terephthalate melt BHET;

[0069] 2. Pre-condensation: Carry out pre-condensation reaction at a temperature of 230-290 ° C and a pressure of 50-1000 Pa for 1.5-2 hours, and discharge when the melt viscosity is 0.3-0.4 dl / g measured by a viscometer;

[0070] 3. Viscosification in liquid phase: Put the above-mentioned melt in a vertical reactor for liquid phase viscosification. The melt enters and distributes from the top, and forms a film naturally under the action of gravity. The vacuum degree in the kettle is 50Pa~100Pa, and the temperature is 280℃ ~295°C, melt residence time 40min~90min. After liquid-phase thickening, the melt...

Embodiment 3

[0072] Example 3: Production of high-modulus low-shrinkage polyester industrial yarn

[0073] 1. Esterification: Put ethylene glycol and phthalic acid in a molar ratio of 1 to 1.3, put in catalyst, trimethyl phosphate, and electrostatic adsorbent to mix into a slurry, and carry out esterification reaction at a temperature of 230 to 260°C to obtain Ethylene terephthalate melt BHET;

[0074] 2. Pre-condensation: Carry out pre-condensation reaction at a temperature of 230-290 ° C and a pressure of 50-1000 Pa for 1.5-2 hours, and discharge when the melt viscosity is 0.3-0.4 dl / g measured by a viscometer;

[0075] 3. Liquid phase thickening: The above melt is subjected to liquid phase thickening in a vertical reactor. The melt enters from the top and distributes freely, and forms a film naturally under the action of gravity. The vacuum degree in the kettle is 70Pa~120Pa, and the temperature is 290 ℃~300℃, the melt residence time is 60min~110min. After liquid-phase thickening, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com