Processing equipment for bearing cage

A bearing cage and processing equipment technology, applied in metal processing equipment, manufacturing tools, feeding devices, etc., can solve the problems of poor manual feeding accuracy, low production efficiency, operation level, proficiency, and physical condition. , to reduce the requirements of operating skills, improve the accuracy of feeding, and reduce the effects of unsafe factors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

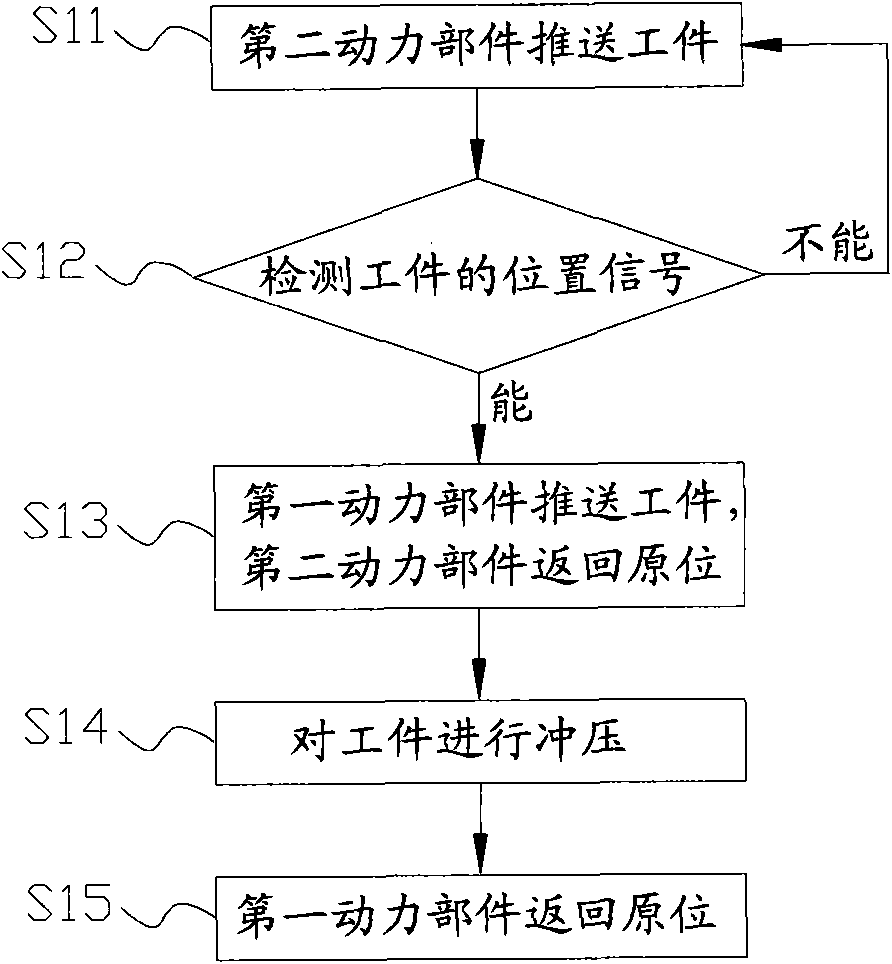

[0022] The core of the present invention is to provide a production equipment for bearing cages, which can effectively improve the production efficiency of bearing cages, reduce the influence of human factors on bearing cages, and improve the production quality of bearing cages.

[0023] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

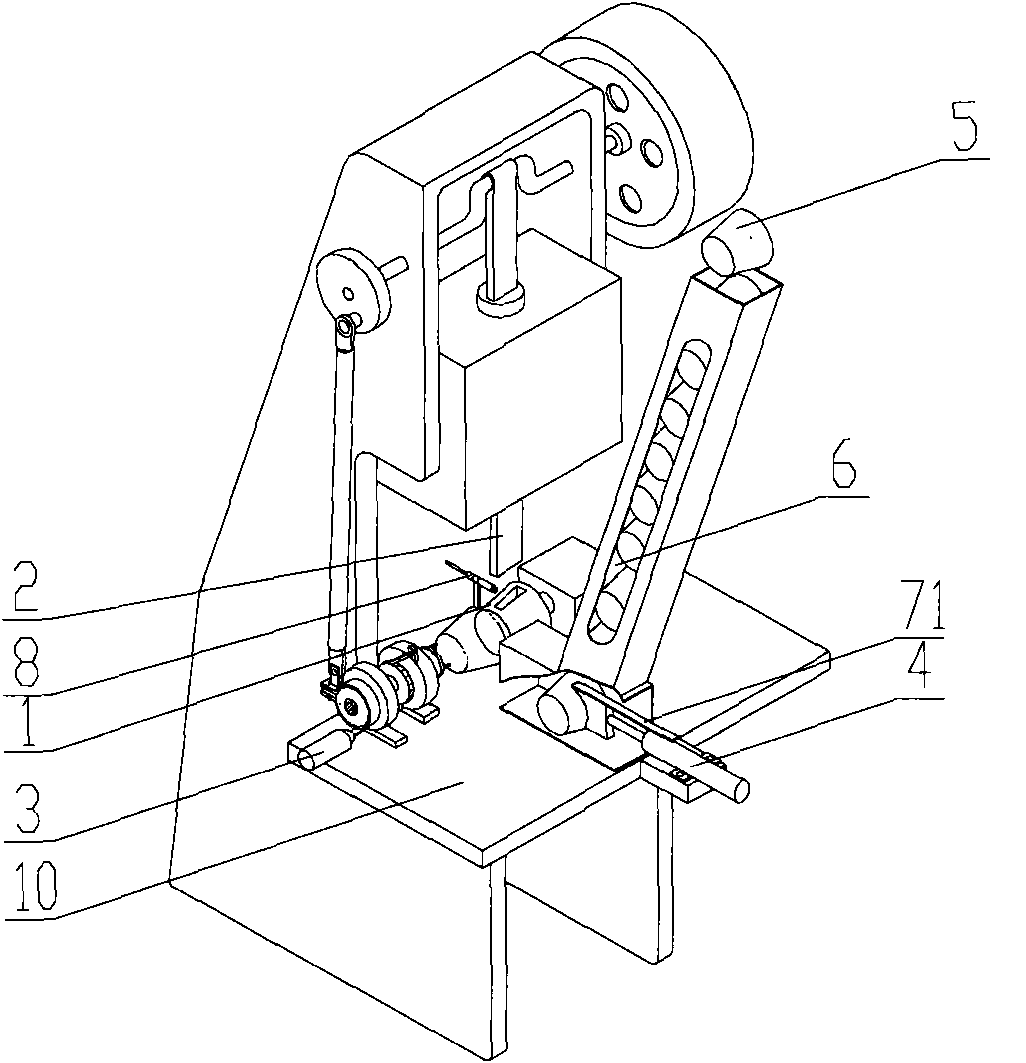

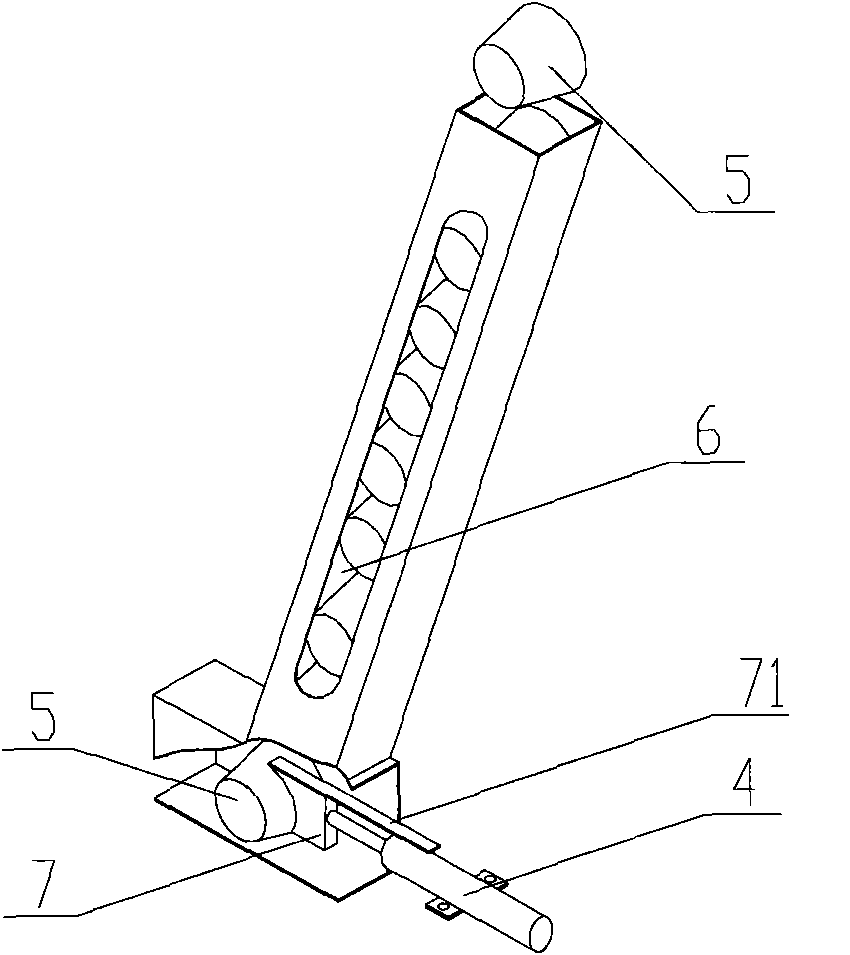

[0024] The upper, lower and other localizers involved in this article are based on figure 1 Processing equipment shown is defined as a baseline. It should be understood that the orientation words used herein shall not limit the protection scope of this patent. Meanwhile, the connections described herein include direct connections and indirect connections.

[0025] Please refer to figure 1 and figure 2 , figure 1 It is a structural schematic diagram o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com