Heat pipe

A heat pipe and pipe body technology, applied in heat exchange equipment, heat exchanger shells, indirect heat exchangers, etc., can solve problems such as cracks, affecting the thermal conductivity of heat pipes, vacuum degree and working fluid leakage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the embodiments with reference to the accompanying drawings.

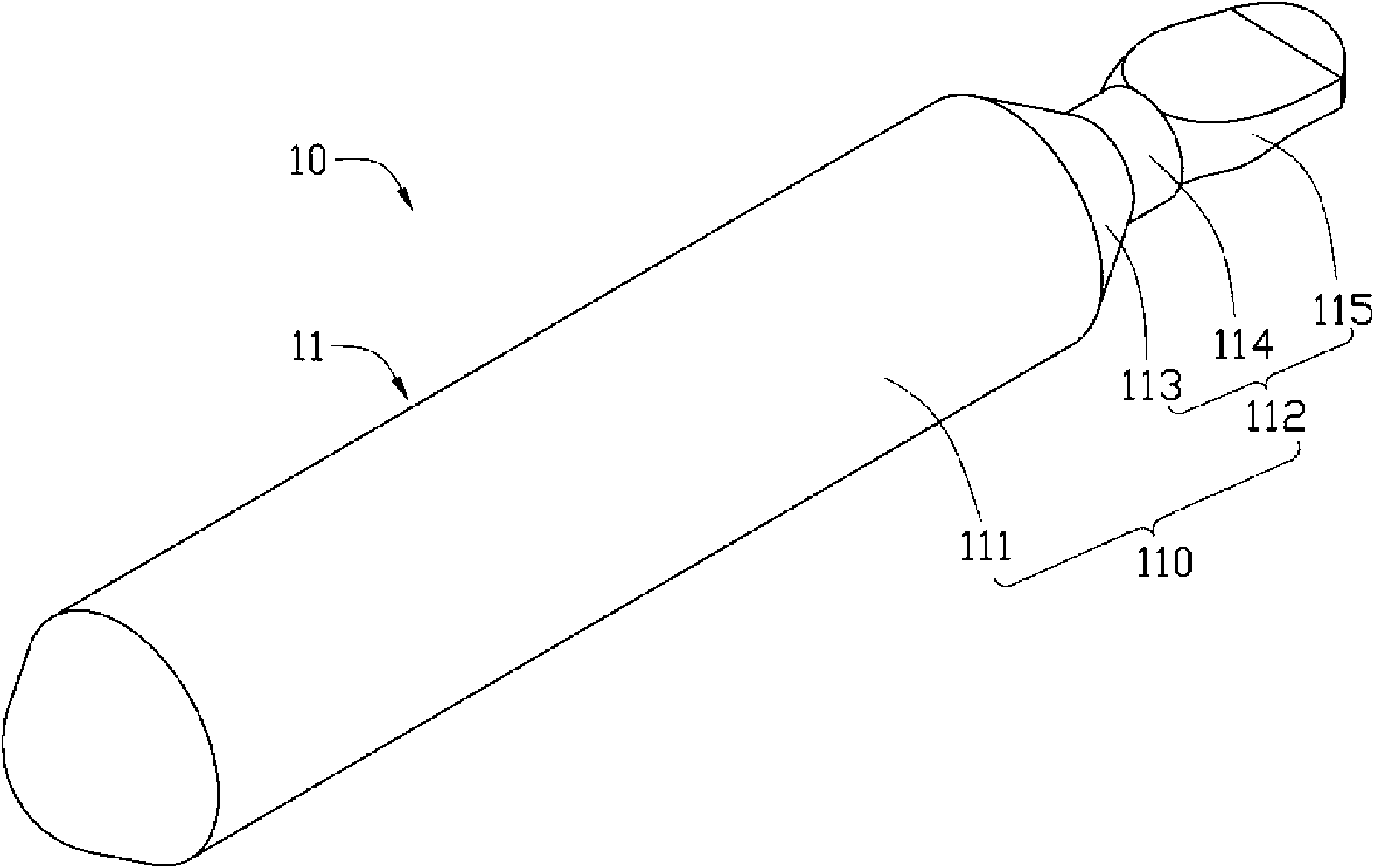

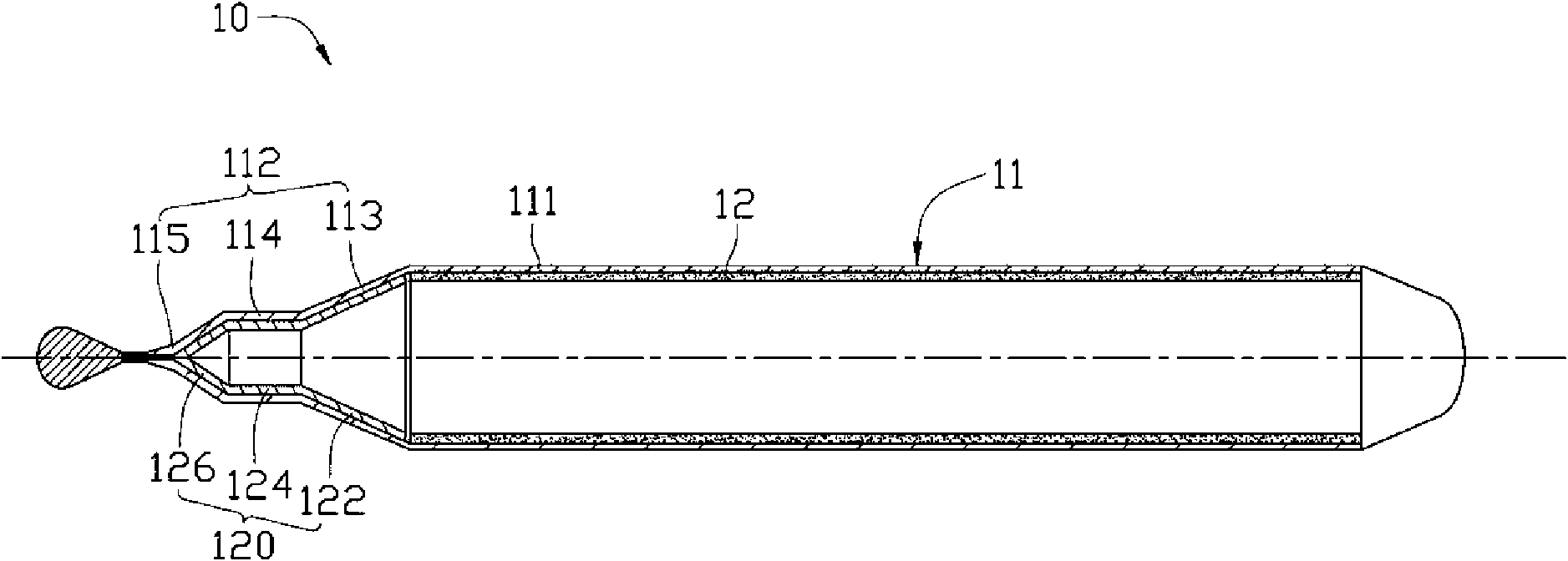

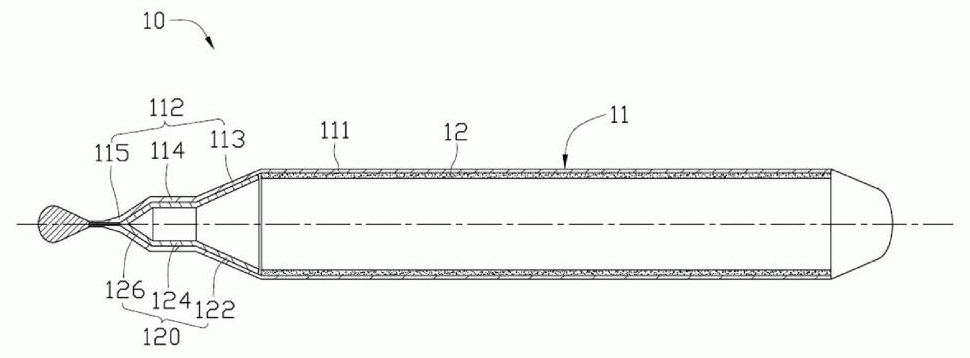

[0010] Such as figure 1 and figure 2 As shown, the heat pipe 10 includes an airtight casing 11 in which a proper amount of working fluid (not shown) is encapsulated, and a capillary structure 12 is provided on the inner wall of the casing 11 .

[0011] The casing 11 includes a tube body 110 and a support body 120 disposed inside one end of the tube body 110 .

[0012] The tube body 110 is made of lightweight titanium. The cross section of the tube body 110 is circular. The tube body 110 includes a cylindrical body 111 and a shrinking tube portion 112 formed at one end of the body 111 . The narrowing portion 112 includes a tapering portion 113 connected to the main body 111 , an extension portion 114 connected to the tapering portion 113 , and a sealing portion 115 formed at the end of the extension portion 114 . The tapered part ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com