Production method of environment-friendly high-surface quality and pickling-free beamsteel

A technology of automobile girder steel and high surface, which is applied in the field of steel rolling, and can solve problems affecting the service life of stamping dies, affecting the production of auto parts, and polluting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

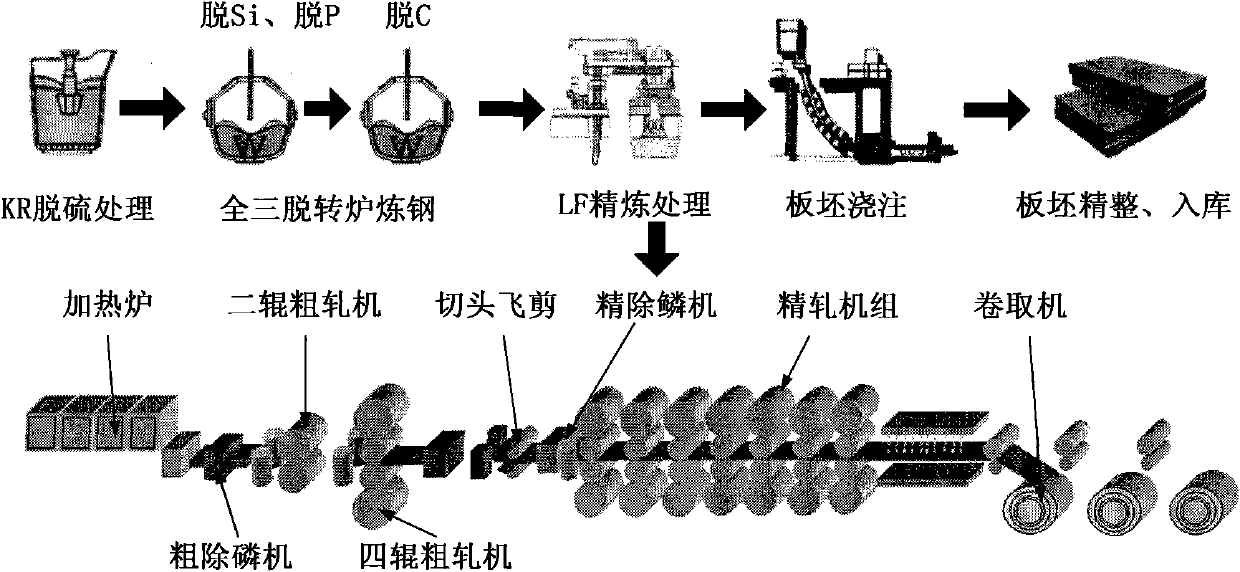

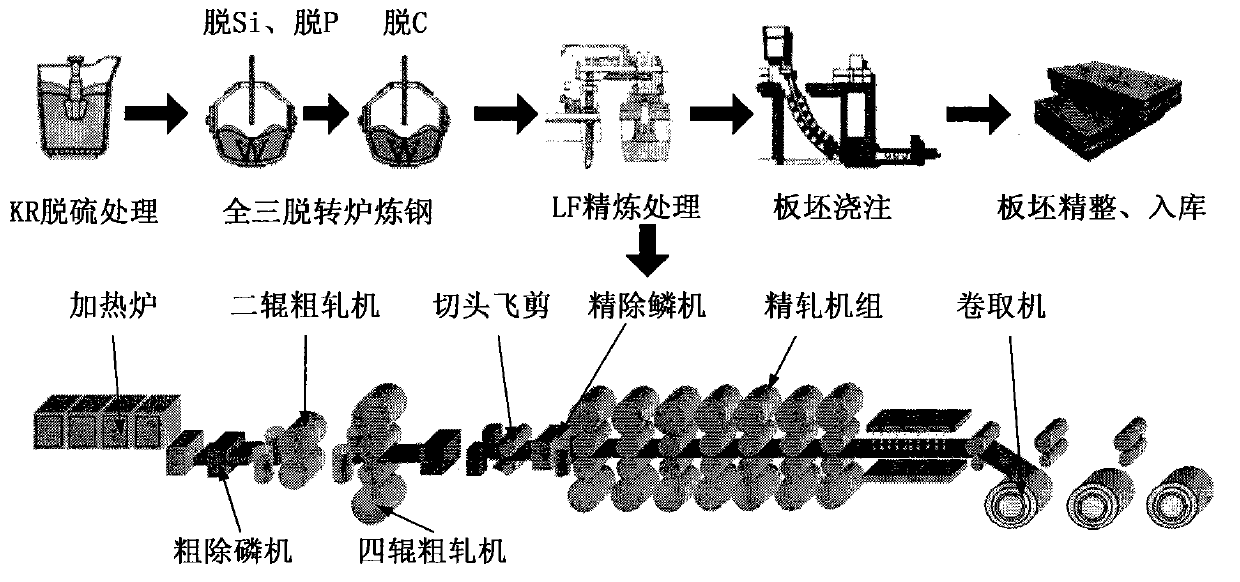

Method used

Image

Examples

Embodiment 1

[0017] The molten iron is subjected to KR desulfurization treatment, full three desulfurization converter, and LF furnace refining treatment, and then continuous casting; the slab smelting composition: C is 0.08wt%, Si is 0.10wt%, Mn is 1.20wt%, P is 0.008 wt%, S is 0.004 wt%, Cr is 0.15 wt%, Nb is 0.03 wt%, and Alt is 0.04 wt%.

[0018] The slab is heated to 1260°C, the heating time is 3.2 hours, the finishing temperature is 890°C, and the coiling temperature is 580°C; in this way, after rough rolling, finishing rolling, and laminar cooling, coiling is carried out. Finally, 510L automobile frame steel was obtained. The yield strength was 410 MPa, the tensile strength was 540 MPa, and the elongation was 32%, the thickness was 8.5 mm, and the width was 1822 mm.

Embodiment 2

[0020] The molten iron is subjected to KR desulfurization treatment, full three desulfurization converter, and LF furnace refining treatment, and then continuous casting; the slab smelting composition: C is 0.09wt%, Si is 0.10wt%, Mn is 1.46wt%, P is 0.008 wt%, S 0.004 wt%, Cr 0.15 wt%, Nb 0.045 wt%, V 0.047 wt%, Ti 0.015 wt%, Alt 0.034 wt%.

[0021] The slab is heated to 1260°C, the heating time is 3.5 hours, the final rolling temperature is 880°C, and the coiling temperature is 560°C; in this way, after rough rolling, finishing rolling, and laminar cooling, coiling is carried out. Finally, 610L automobile frame steel was obtained. The yield strength was 535 MPa, the tensile strength was 640 MPa, and the elongation was 25%, the thickness was 9.8 mm, and the width was 1732 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com