Novel protein glycosylation grafting method

A technology of protein glycosylation and glycosylated protein, which is applied in the field of protein glycosylation grafting to achieve the effect of overcoming uneven reaction and strong industrial operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

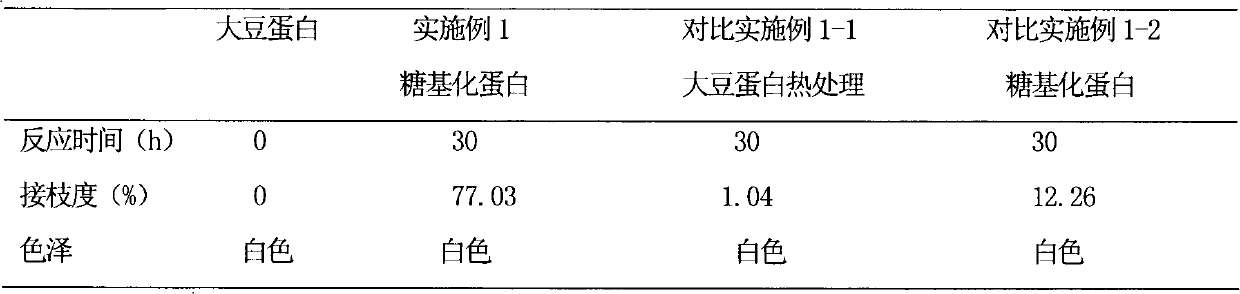

Embodiment 1

[0036] Accurately weigh 0.5g soybean protein and 1.5g dextran, dissolve in 10mL 0.01mol / L sodium phosphate buffer solution with pH 6.5, stir at room temperature for 2h, add 3 drops of NaN 3 (0.02% w / w) for anti-corrosion, placed at 5°C for 24h, kept at a constant temperature of 60°C, and stirred for 30h at a stirring speed of 500r / min. After the reaction is completed, the reaction is rapidly cooled to room temperature to terminate the reaction, and freeze-dried to obtain a glycosylated protein product.

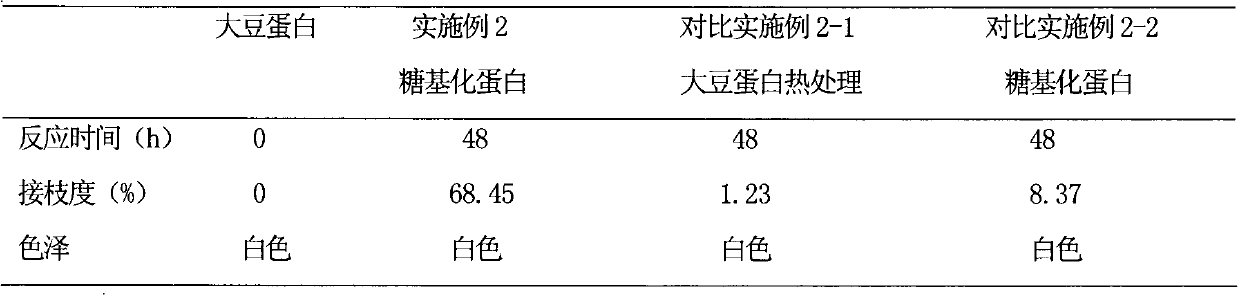

Embodiment 2

[0046]Put 1g of PEG2000 as a crowding reagent in the reaction device, add 10mL of 0.01mol / L sodium phosphate buffer solution with pH 7.0, stir for 2 hours to make it fully hydrated and dissolved, add 0.2g of soybean protein and 0.6g of dextran to the crowding In the solution of the reagent, after fully stirring for 2 hours, add NaN 3 (0.02% w / w) anti-corrosion, placed at 5°C for 24h, stirred at 50°C for 48h, cooled rapidly to 24°C after the reaction to obtain glycosylated protein product, purified by gel filtration chromatography to remove unreacted protein and glucose Polysaccharides and inert polymer PEG2000.

Embodiment 3

[0055] Accurately weigh 0.6g soybean protein and 3.6g dextran, dissolve in 20mL 0.01mol / L sodium phosphate buffer solution with pH 7.5, stir at room temperature for 2h, add 3 drops of NaN 3 (0.02% w / w) for anti-corrosion, placed at 5°C for 24h, kept at a constant temperature of 70°C, and stirred at a stirring speed of 500r / min for 12h. After the reaction was completed, it was rapidly cooled to room temperature to terminate the reaction, and freeze-dried.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com