Utilization method for polymeric aluminium reaction residues

A polyaluminum chloride and reaction technology are applied in the field of treatment and utilization of polyaluminum chloride reaction residues to achieve the effects of reducing the content of water-insoluble matter, reducing usage, and facilitating transportation and utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0013] The total acidity of the inorganic mixed acid in this example is 6% (in HCl mass fraction), which is formed by mixing 6% hydrochloric acid, 8% sulfuric acid and 5.4% phosphoric acid, and the mass ratio of the three is 80:1:1.

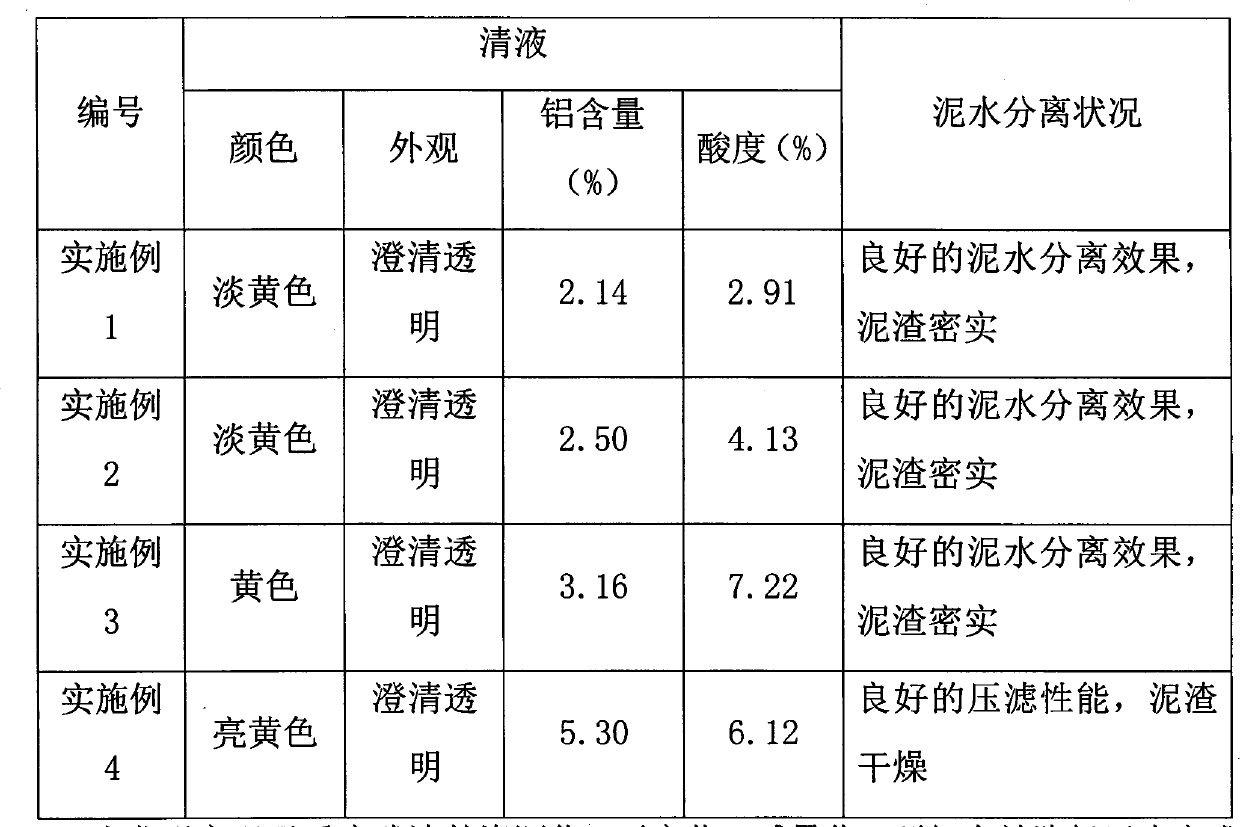

[0014] Add 3600kg of 5% mixed mineral acid in a 5000L reactor, add 600kg of polyaluminum chloride reaction residue successively under continuous stirring, heat and stir at about 50°C for 0.5 hours, then pour the reaction solution into a sedimentation tank for precipitation for 1 hour to obtain The supernatant liquid is the alumina-containing acid liquid, and the specific properties and characteristics of the sludge and the reaction liquid are shown in Table 1.

Embodiment 2

[0016] The total acidity of the inorganic mixed acid of this example is 8% (in terms of HCl mass fraction), which is formed by mixing 8% hydrochloric acid and 10.7% sulfuric acid, and the mass ratio of the two is 30:1.

[0017] Add 3600kg of 8% mixed mineral acid in a 5000L reactor, add 720kg of polyaluminum chloride reaction residue successively under constant stirring, heat and stir at about 70°C for 1 hour, then pour the reaction solution into the sedimentation tank for 0.5 hour precipitation, and obtain The supernatant liquid is the alumina-containing acid liquid, and the specific properties and characteristics of the sludge and the reaction liquid are shown in Table 1.

Embodiment 3

[0019] The total acidity of the inorganic mixed acid of this example is 12% (in HCl mass fraction), which is formed by mixing 12% hydrochloric acid, 16.1% sulfuric acid and 10.7% phosphoric acid, and the mass ratio of the two is 80:1:3.

[0020] Add 3600kg of 12% mixed mineral acid in a 5000L reactor, add 900kg of polyaluminum chloride reaction residue successively under constant stirring, heat and stir at about 90°C for 1.5 hours, then pour the reaction solution into a sedimentation tank for precipitation for 2 hours to obtain The supernatant liquid is the alumina-containing acid liquid, and the specific properties and characteristics of the sludge and the reaction liquid are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com