Rice-wheat combined harvester

A combine harvester, rice and wheat technology, applied in the direction of harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of self-heavy, bulky, difficult to adapt to the needs of important farming seasons and important links, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

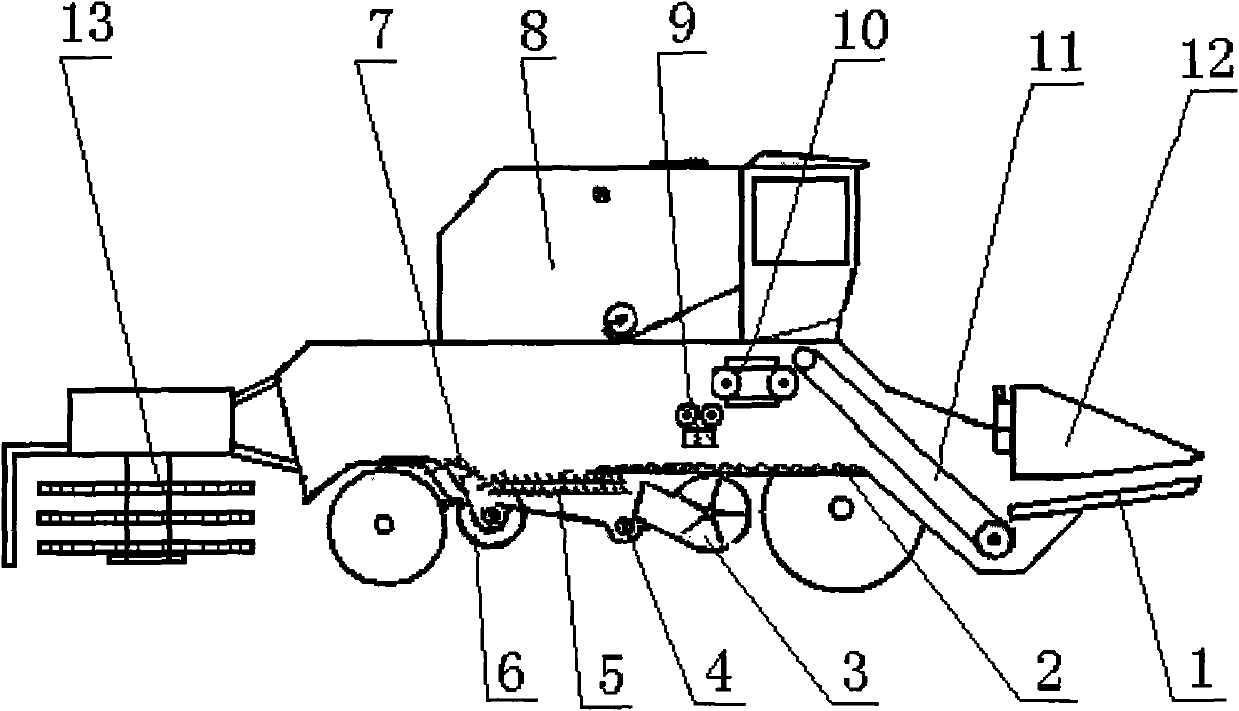

[0011] Such as figure 1 As shown, a rice and wheat combine harvester includes a body, a cutter 12, a fringe bearing plate 1, an inclined conveyor 11, an fringe drying mechanism 10, a threshing mechanism 9, a grain box 8, an auger 4, and a grain cleaning mechanism With the stalk pulverizer 13, the cutter 12 is positioned at the front end of the body, the fringe plate 1 is arranged below the cutter 12, the fringe plate 1 has an inclined conveyer 11 beside the fringe plate 1, and the fringe drying mechanism 10 is arranged on the side of the inclined conveyer 11 top. The threshing mechanism 9 is arranged below the afterbody of the first drying mechanism 10, and the afterbody of the straw pulverizer 13 is detachably connected to the body. The threshing mechanism 9 includes a threshing transmission part, two rollers rotating in opposite directions and a fringe rubbing part, and the fringe rubbing part is arranged directly under the rollers. The grain cleaning mechanism is located b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com