Preparation method of optical activity layer of polymer solar cell

A technology for solar cells and photoactive layers, applied in circuits, photovoltaic power generation, electrical components, etc., can solve problems such as difficult removal of surface modifiers, dispersants, impact on solar cell device performance, complexity, etc., to improve light absorption performance and carrier transport performance, improved photoelectric conversion efficiency, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

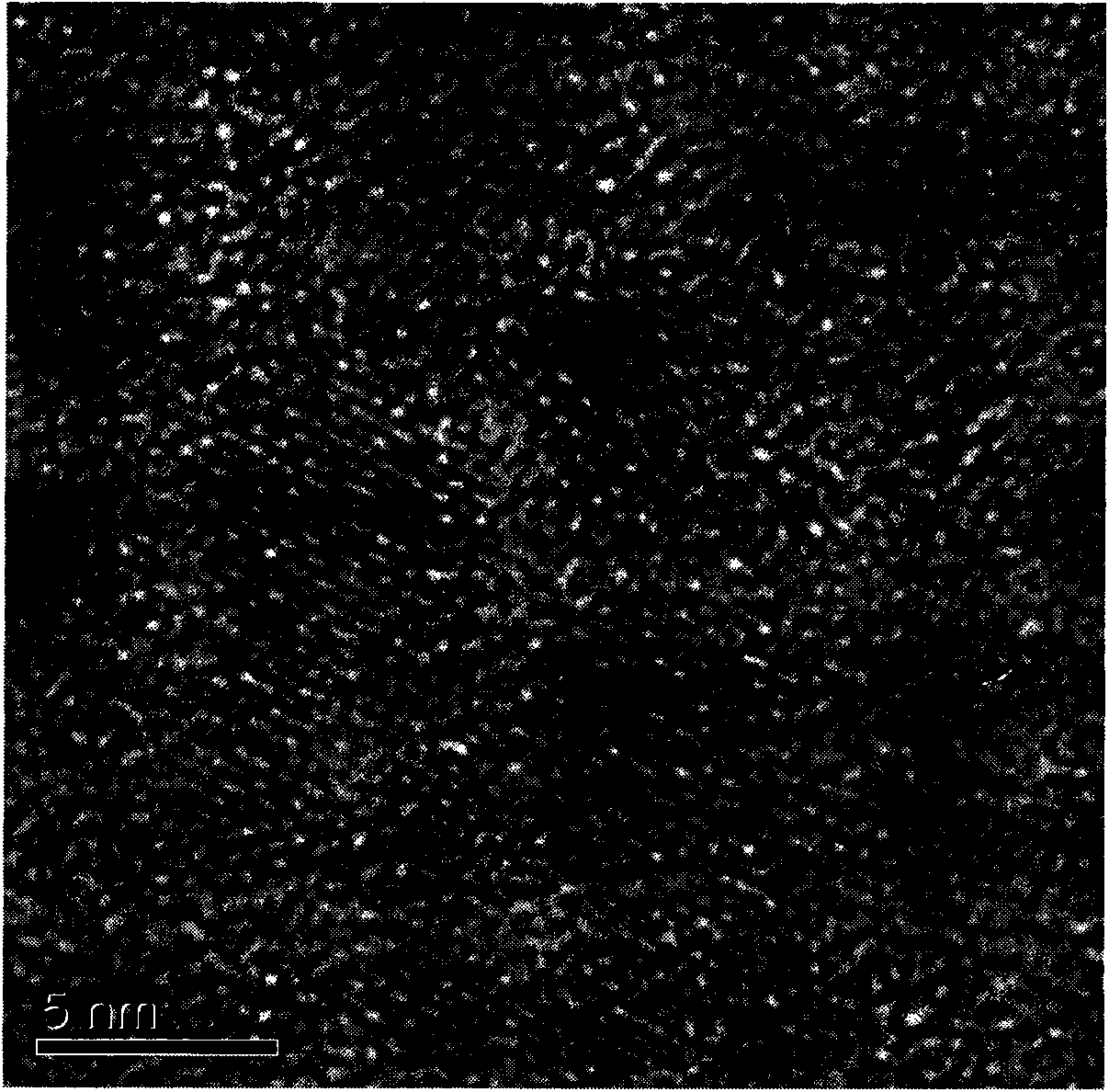

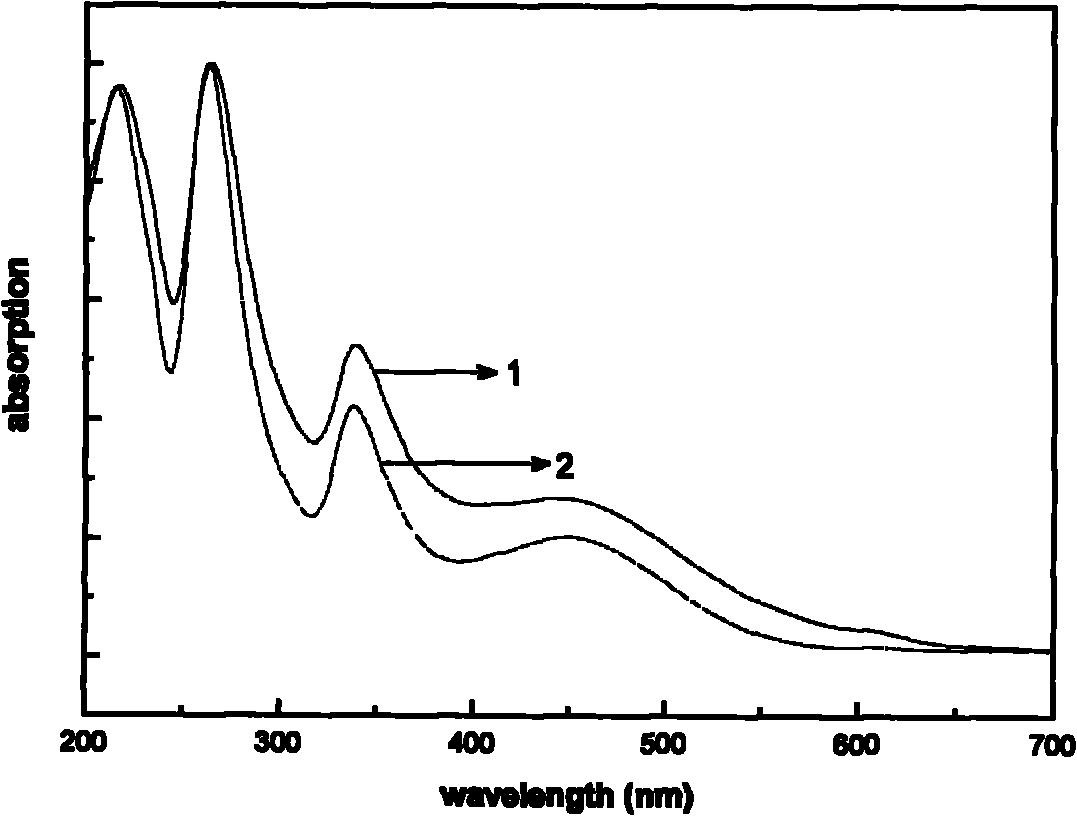

[0027] (1) Dissolve lead methacrylate in methacrylic acid to obtain a solution of 1440mg / mL; (2) Combine poly(3-hexyl)thiophene (P3HT) and C with a mass ratio of 1:1 60 Dissolve in o-dichlorobenzene to obtain a solution with a P3HT concentration of 17mg / mL. Place the solution at 50°C and stir for 12 hours to fully dissolve; (3) Mix the above two solutions at a volume ratio of 1:20. Stir at 50℃ for 12 hours, spin-coated film, place the composite film in H at room temperature 2 In an atmosphere of S for 1 hour, a photoactive film doped with PbS nanocrystals is obtained. The size of the nanocrystals is 3-6nm as measured by high-resolution transmission electron micrographs, such as figure 1 As shown, calculated by the reaction equation, the mass percentage of PbS nanocrystals is 43.4%, the mass percentage of poly(3-hexyl)thiophene (P3HT) is 28.3%, C 60 The mass percentage content is 28.3%. The PbS nanocrystal-doped photoactive film spin-coated on PEDOT:PSS / ITO was vapor-deposited wit...

Embodiment 2

[0029] (1) Dissolve lead methacrylate in methacrylic acid to obtain a solution of 1440mg / mL; (2) Combine poly(3-hexyl)thiophene (P3HT) and C with a mass ratio of 1:1 60 Dissolve in o-dichlorobenzene to obtain a solution with a P3HT concentration of 17mg / mL. Place the solution at 50°C and stir for 12 hours to fully dissolve; (3) Mix the above two solutions at a volume ratio of 1:20. Stir at 50℃ for 12 hours, spin-coated film, place the composite film in H at room temperature 2 In a Se atmosphere for 1 hour, a photoactive film doped with PbSe nanocrystals was obtained. The size of the nanocrystals was 3-6nm measured by high-resolution transmission electron microscopy. The mass percentage of PbSe nanocrystals was calculated by the reaction equation to be 51.8%. The mass percentage of (3-hexyl)thiophene (P3HT) is 24.1%, C 60 The mass percentage content is 24.1%. The photoactive film doped with PbSe nanocrystals spin-coated on PEDOT:PSS / ITO was vapor-deposited with a metal aluminum e...

Embodiment 3

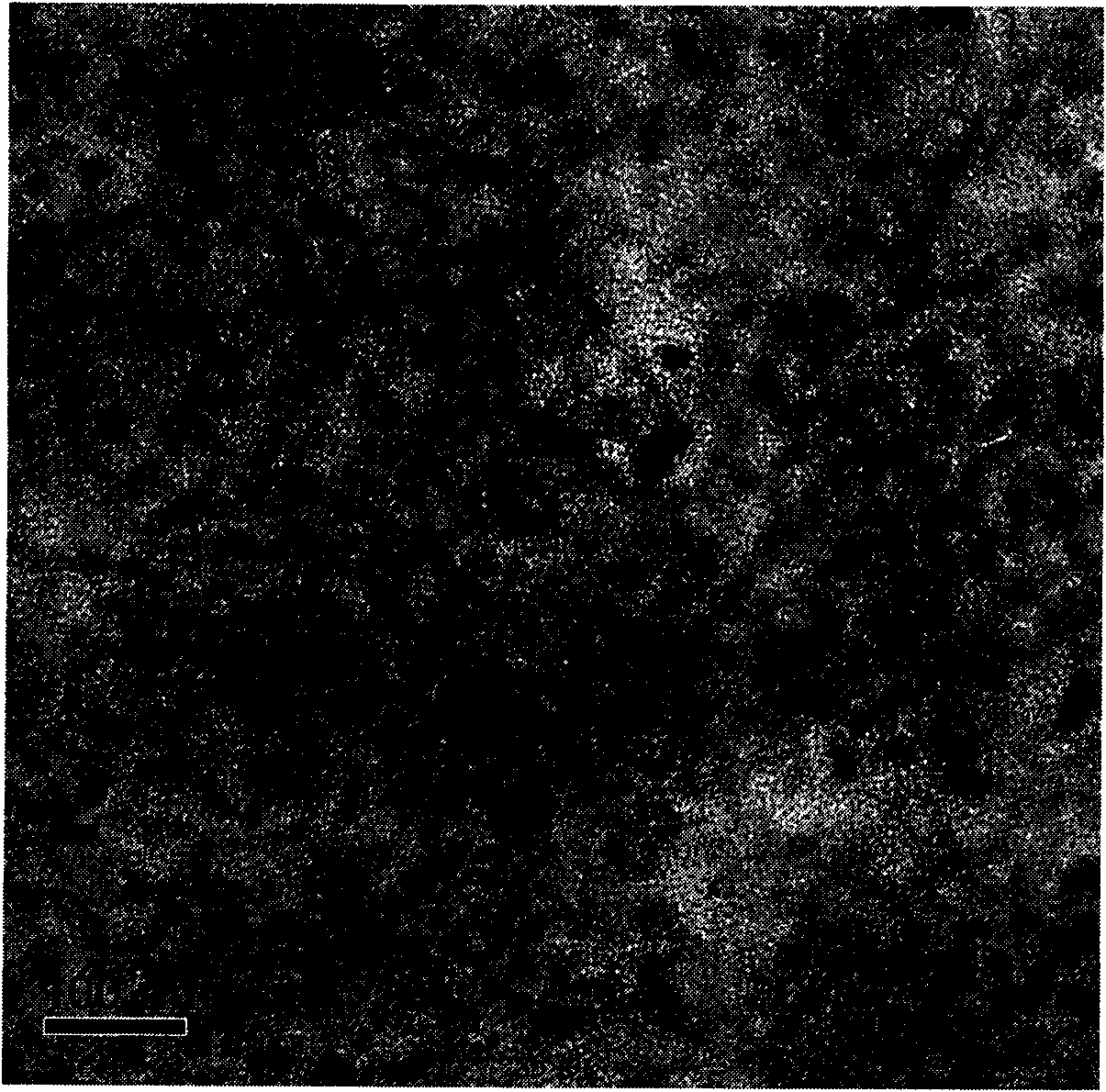

[0031] (1) Dissolve lead methacrylate in methacrylic acid to obtain a solution of 240mg / mL; (2) Combine poly(3-hexyl)thiophene (P3HT) and C with a mass ratio of 1:1 60 Dissolve in o-dichlorobenzene to obtain a solution with a P3HT concentration of 17mg / mL. Place the solution at 50°C and stir for 12 hours to fully dissolve; (3) Mix the above two solutions at a volume ratio of 1:5. Stir at 50℃ for 12 hours, spin-coated film, place the composite film in H at room temperature 2 In an S atmosphere for 1 hour, a photoactive film doped with PbS nanocrystals is obtained, the size of the nanocrystals is 10-40nm, such as figure 2 As shown, the mass percentage of PbS nanocrystals calculated by the reaction equation is 37.2%, and the mass percentage of poly(3-hexyl)thiophene (P3HT) is 31.4%, C 60 The mass percentage content is 31.4%. The PbS nanocrystal-doped photoactive film spin-coated on PEDOT:PSS / ITO was vapor-deposited with a metal aluminum electrode to obtain a polymer solar cell. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com