Guide die structure for growing extra-thick monocrystal alumina wafer

A single-crystal alumina, extra-thick technology, applied in the directions of single-crystal growth, crystal growth, single-crystal growth, etc., can solve the problem of unsuitable growth of extra-thick large single-crystal alumina sheets, complex crystallizer core structure, and single crystal growth. Alumina sheet cracking and other problems, to achieve the effect of simple structure, high qualified rate of finished products and stable temperature field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

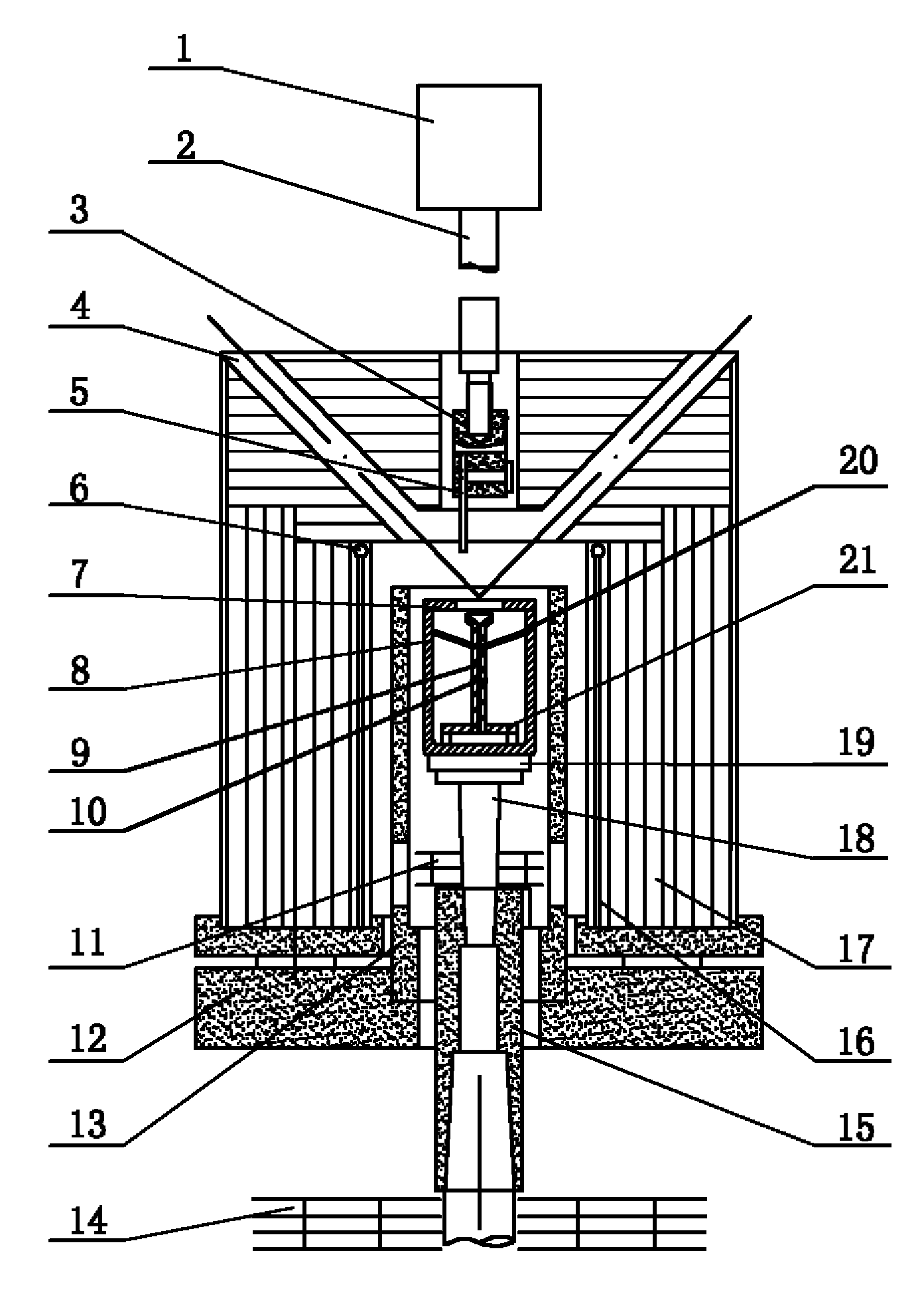

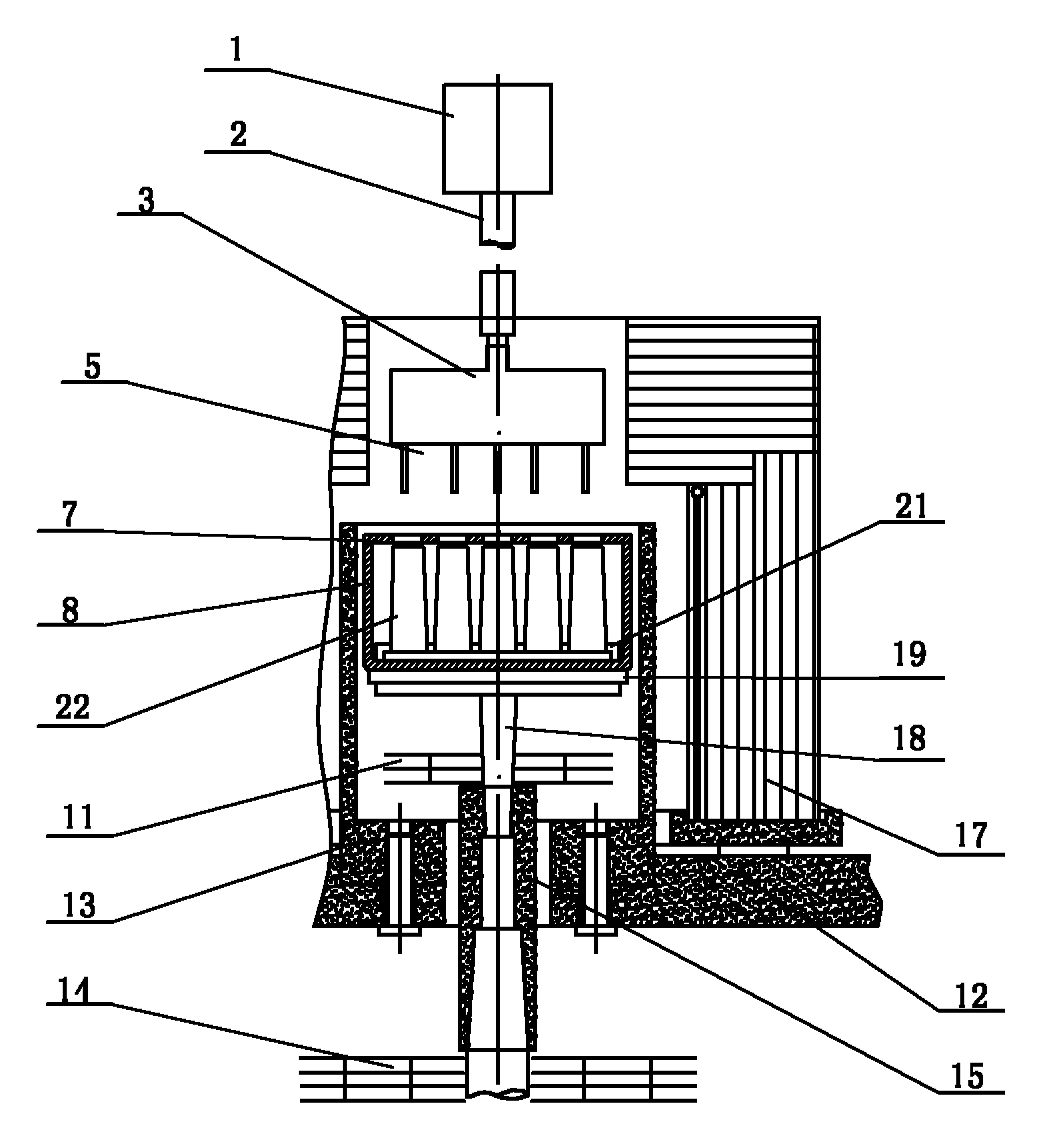

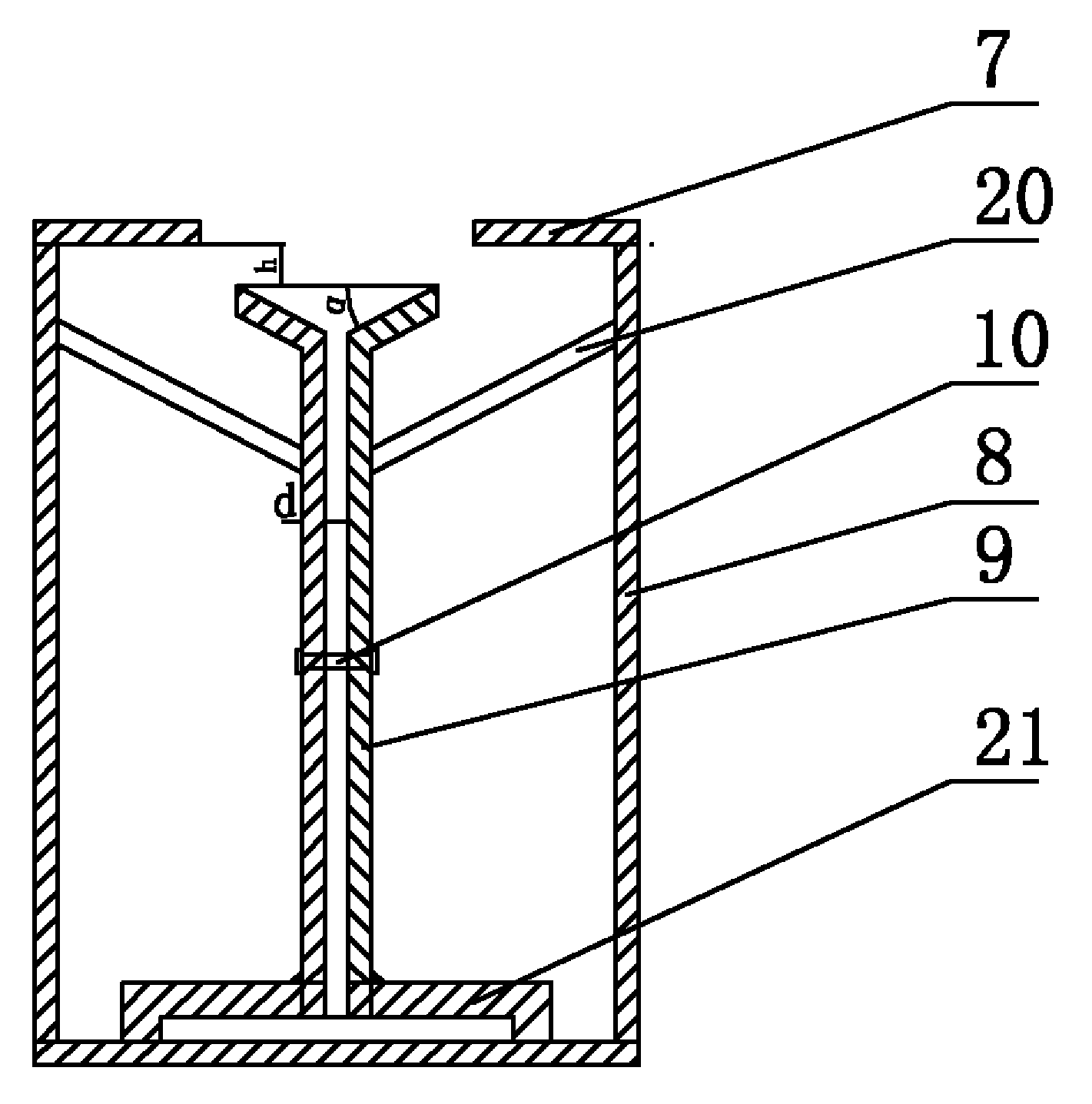

[0010] See figure 1 , figure 2 and image 3 , the present invention comprises crucible 8, and crucible 8 is installed in heater 13 by handle 18, and heater 13 is installed in electrode plate 12, and heater 13 is provided with insulation screen 17, and crucible 8 is provided with crystallizer 22, and crystallizer 22. A seed crystal 5 is arranged above the crystallization table, and the seed crystal 5 is connected to the seed crystal shaft sleeve 1 through a connection structure. It is connected with the seed crystal 5 by screws, the crucible 8 is in the shape of a cuboid or a rectangular bar with circular arcs at both ends, and the crystallizers 22 are arranged sequentially along the centerline of the length direction of the crucible 8. In this embodiment, the crystallizers 22 Five are arranged along the center line of the length direction of the crucible 3, and the heater 13 is a rectangular parallelepiped or a rectangular strip with circular arcs at both ends; the crystall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com