Method for forming amino acid self-assembly corrosion inhibition membrane with fluorescent characteristics on copper surface

A technology with fluorescent properties and amino acids, which is applied in the coating process of metal materials, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The copper samples were polished step by step with metallographic sandpaper (1#-6#), then degreased with absolute ethanol, and finally rinsed with deionized water. Soak the above copper sample in 0.0001mol / L DL-cysteine solution for three hours (pH=5~6), take it out and rinse it with deionized water twice to remove the adsorbate around the electrode, and dry the electrode That is, a Cys / Cu electrode is obtained. The Cys / Cu electrode prepared above was acidified in 0.5mol / L HCl solution for ten minutes, and after the acidified electrode was rinsed with high-purity water, in 0.0001mol / L fluorescent reagent 1-Naphthylamine diacetate (NADA) aqueous solution Soak for 1 hour and keep the pH between 5 and 6. Rinse twice with deionized water, blow dry with nitrogen, and the double-layer membrane electrode is assembled, and a NADA / Cys / Cu double-layer membrane electrode with fluorescence characteristics is obtained, which is stored away from light.

Embodiment 2

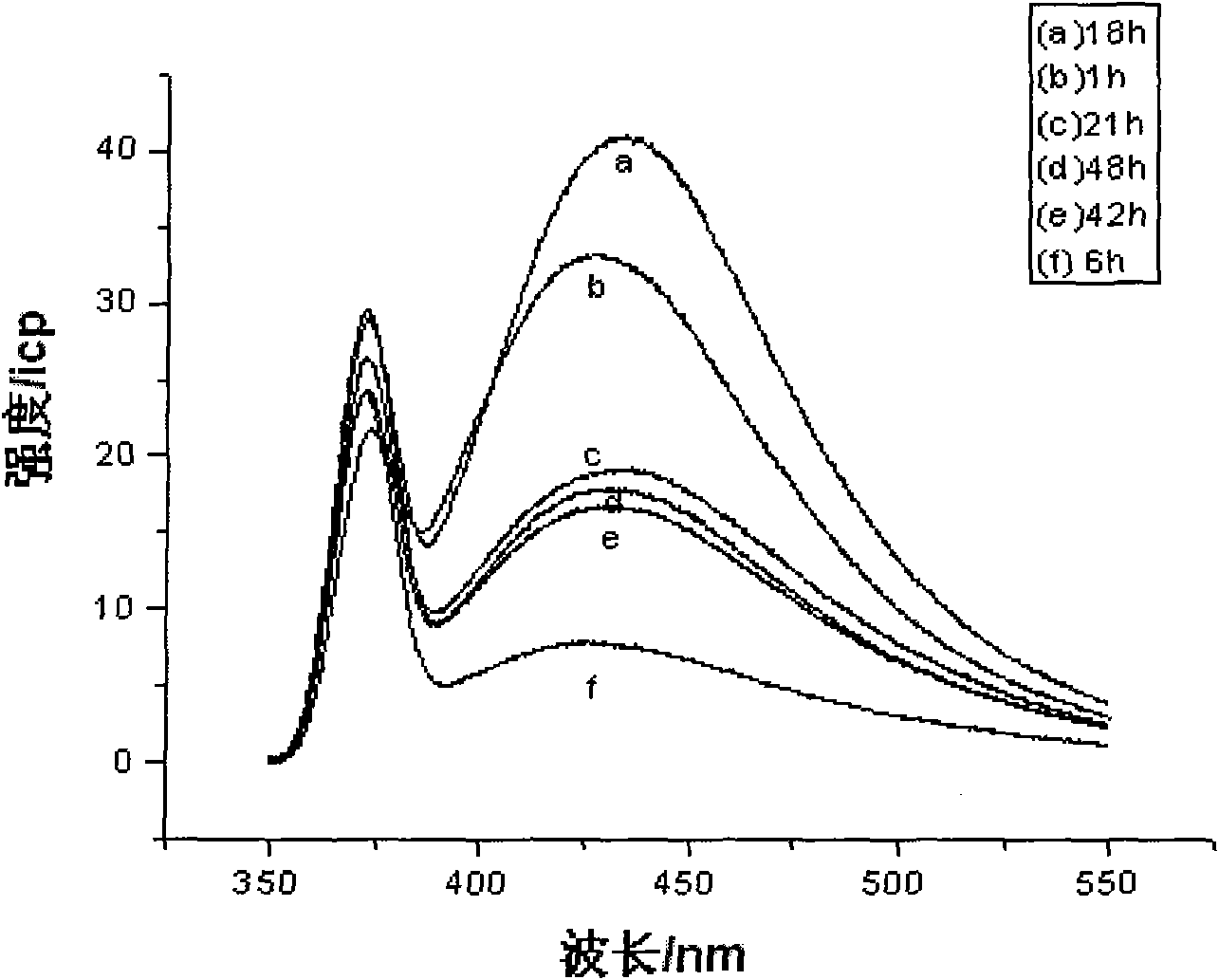

[0028] Fluorescence spectrum measurement was performed on the NADA / Cys / Cu bilayer film electrode obtained in Example 1. figure 1 Fluorescence spectra of NADA / Cys / Cu fluorescent double-layer self-assembled membrane electrode soaked in 0.5M NaCl solution for different time. From figure 1 It can be seen that there are two peaks in the fluorescence emission spectrum, the peak at 375nm is the Rayleigh scattering peak, and the peak at around 420nm is the fluorescence absorption peak of the NADA / Cys / Cu bilayer film. The intensities of fluorescence peaks after different soaking times are shown in Table 1. From Table 1, it can be seen that the fluorescence intensity of fluorescent double-layer membrane electrodes does not show a single increase or decrease trend over time, but decreases, increases, and then decreases. and re-increasing periodic changes.

[0029] Table 2 Fluorescence peak intensities of NADA / Cys / Cu double-layer membrane electrode soaked in 0.5M NaCl solution for diffe...

Embodiment 3

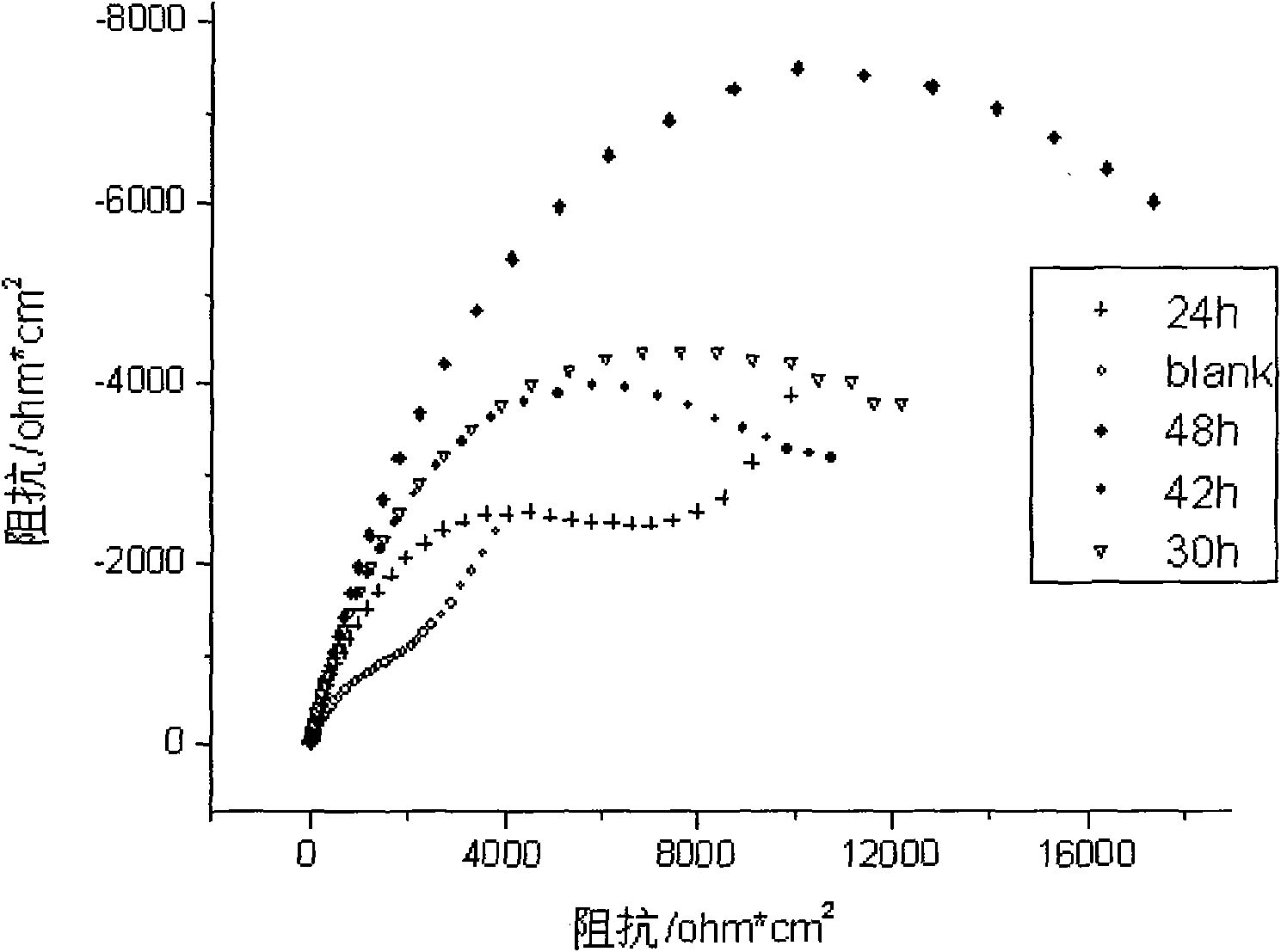

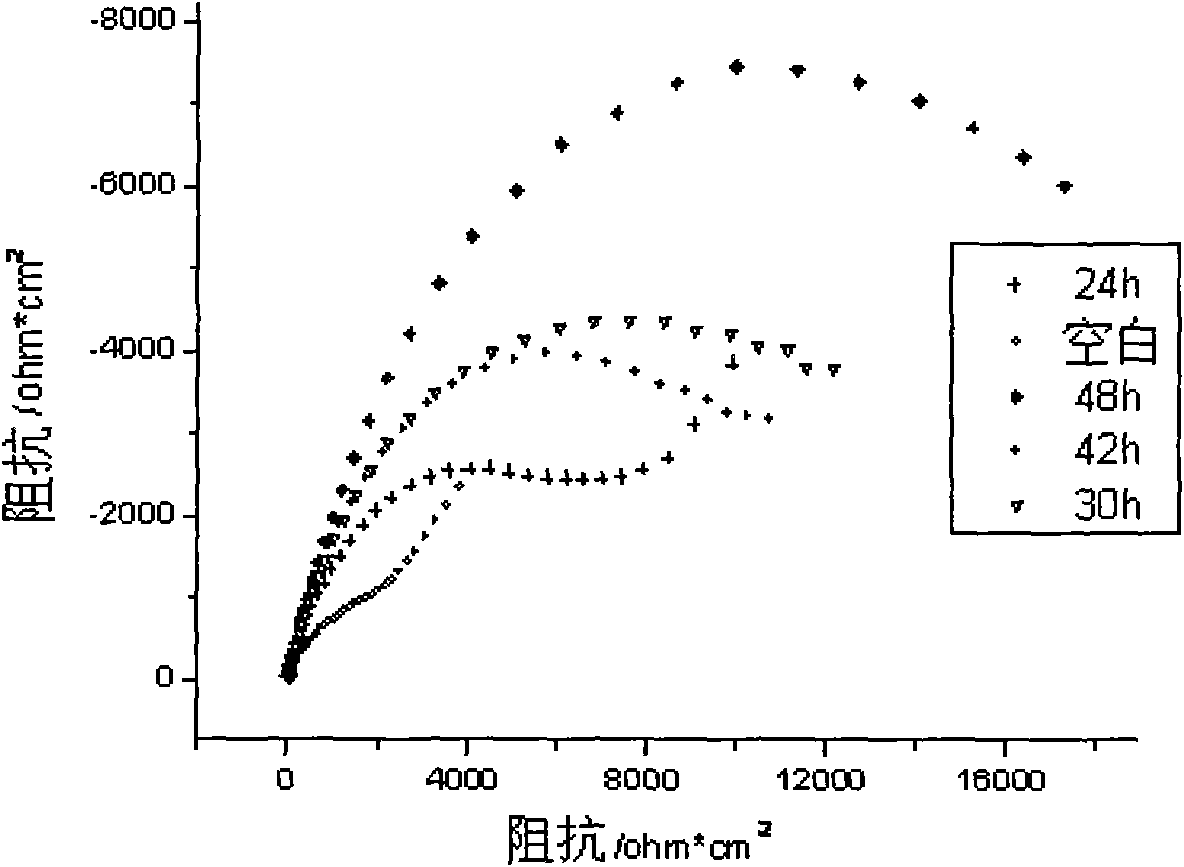

[0032] The electrochemical impedance spectrum of the NADA / Cys / Cu bilayer film electrode obtained in Example 1 was measured. figure 2 It is the electrochemical impedance spectroscopy of NADA / Cys / Cu fluorescent bilayer self-assembled film electrode soaked in 0.5M NaCl solution for different time. image 3 Nyquist plots of NADA / Cys / Cu double-layer membrane electrode soaked in 0.5M NaCl solution for different times. From figure 2 neutralize image 3 It can be seen that with the increase of time, the electrical uuxe resistance of the double-layer film electrode does not show a single increase or decrease trend, but a periodic change of decrease, increase, decrease and increase again, which corresponds to The protective film on the surface of the copper electrode is continuously damaged and then repaired.

[0033] The corrosion resistance of the electrode is determined by the electrochemical polarization resistance Rp, which is given by:

[0034]

[0035] In the formula, Re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com