Water-borne phenolic epoxy resin emulsion and preparation method thereof

A novolac epoxy resin, water-based technology, applied in the direction of epoxy resin coatings, coatings, etc., can solve the problems of full water-based novolac epoxy resin, many functional groups, large molecular hindrance, etc., to achieve excellent adhesion, color and luster Shallow, stable and good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

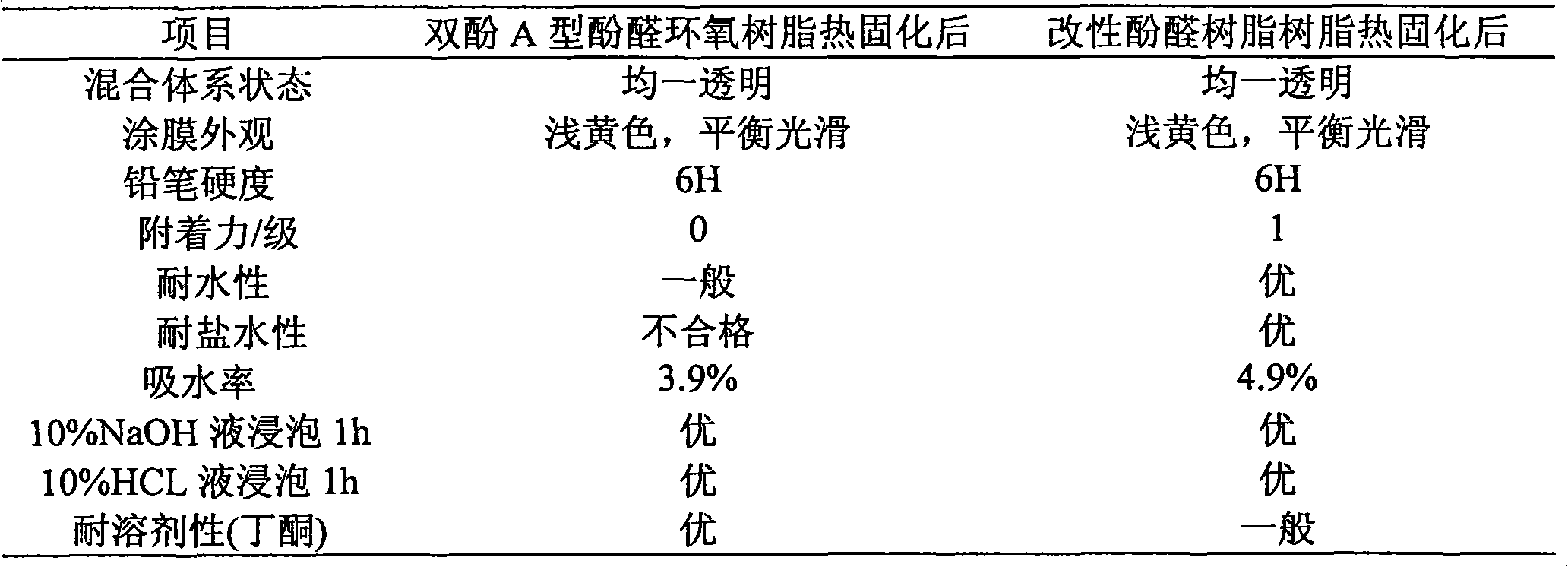

Examples

Embodiment 1

[0038] A kind of raw material formula of water-based novolac epoxy resin emulsion is:

[0039] Bisphenol A Novolak Epoxy Resin 30g

[0040] Dioxane 10g

[0041] p-aminobenzoic acid 4g

[0042] Sodium Lauryl Sulfate SDS 5g

[0043] Ethanolamine 2g

[0044] Distilled water 30g

[0045]During preparation, the bisphenol A type novolak epoxy resin (epoxy equivalent is 220g / eq) and dioxane in the material formula are added to the 500mL reaction kettle equipped with stirring device, condensation device, thermometer and dry nitrogen system In the process, heat until the bisphenol A novolak epoxy resin is completely dissolved, raise the temperature to 85°C, add p-aminobenzoic acid, react for 60h, add the surfactant sodium dodecyl sulfate SDS for auxiliary emulsification, cool down to 40°C, Add neutralizing agent ethanolamine, under high-speed stirring (2000rpm) condition, slowly add distilled water and carry out phase inversion in 2min, make aqueous novolac epoxy resin emulsion, i...

Embodiment 2

[0051] A kind of raw material formula of water-based novolac epoxy resin emulsion is:

[0052] O-methyl novolac epoxy resin 35g

[0053] Dioxane 15g

[0054] Thioglycolic acid 3g

[0055] Octylphenol Ethoxylate X-405 3g

[0056] 2-Dimethylamino-2-methyl-1-propanol 4g

[0057] Distilled water 30g

[0058] During preparation, the o-methyl novolac epoxy resin (epoxy equivalent is 210g / eq) and dioxane in the material formula are added to the 500mL reactor equipped with stirring device, condensation device, thermometer and dry nitrogen system , heat until it is completely dissolved, raise the temperature to 100°C, add thioglycolic acid to react for 4 hours, add surfactant octylphenol polyoxyethylene ether X-405 for auxiliary emulsification, cool down to 60°C, add neutralizing agent 2-dimethyl Amino-2-methyl-1-propanol, under the condition of high-speed stirring (2000rpm), slowly add distilled water and carry out phase inversion in 2min, make aqueous novolak epoxy resin emulsio...

Embodiment 3

[0060] A kind of raw material formula of water-based novolac epoxy resin emulsion is:

[0061] Bisphenol A Novolak Epoxy Resin 40g

[0062] Dioxane 18g

[0063] p-aminobenzoic acid 5g

[0064] Nonylphenol polyoxyethylene ether NP-10 3g

[0065] N,N-Dimethylethanolamine 3g

[0066] Distilled water 50g

[0067] During preparation, the bisphenol A type novolak epoxy resin (epoxy equivalent is 220g / eq) and dioxane in the material formula are added to the 500mL reaction kettle equipped with stirring device, condensation device, thermometer and dry nitrogen system In the medium, heat until it is completely dissolved, then raise the temperature to 95°C, add p-aminobenzoic acid to react for 10 hours, add surfactant nonylphenol polyoxyethylene ether NP-10 for auxiliary emulsification, cool down to 60°C, add neutralizing agent N , N-dimethylethanolamine, under high-speed stirring (2000rpm) condition, slowly distilled water carries out phase inversion in 2min, makes aqueous novolak ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com