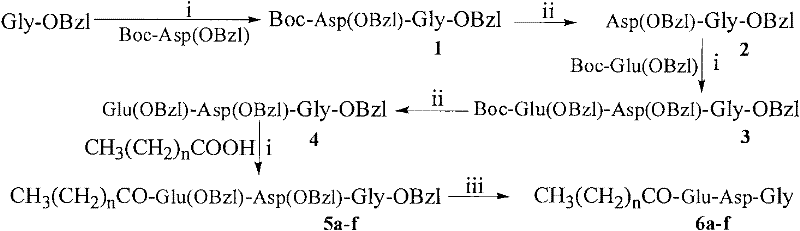

Saturated fatty chain acid Glu-Asp-Gly tripeptide amide, synthetic method and application thereof

A technology of glu-asp-gly and fatty chain acid, which is applied in the direction of tripeptide ingredients, medical preparations of non-active ingredients, non-effective ingredients of polymer compounds, etc., can solve the problem of cyclosporin A's poor water solubility, dosage form and curative effect Unsatisfactory, strong nephrotoxicity and other problems, to achieve excellent immunosuppressive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Preparation of Boc-Asp(OBzl)-Gly-OBzl

[0029] 8.08g (25.00mmol) Boc-Asp (OBzl) was dissolved in 200ml dry THF, 3.38g (25.00mmol) N-hydroxybenzotriazole (HOBt) was added to the resulting solution under ice bath, and completely dissolved. After 10 minutes, 6.20 g (30 mmol) of dicyclohexylcarbodiimide (DCC) was added to obtain the reaction solution (I), which was set aside. Under ice bath, 8.43g (25.00mmol) TosH·Gly-OBzl was suspended in 20ml anhydrous THF, and then 1ml N-methylmorpholine (NMM) was added to adjust the pH to 8-9. Stir for 35 minutes to obtain reaction solution (II), which is set aside. The reaction solution (I) was added to the reaction solution (II) in an ice bath, and the mixture was stirred for 1 h under ice bath, and then stirred at room temperature for 12 h. TLC (chloroform / methanol, 10:1) showed that Boc-Asp(OBzl)-OH disappeared. Dicyclohexylurea (DCU) was filtered off, and THF was removed under reduced pressure. The residue was dissolved ...

Embodiment 2

[0030] Example 2 Preparation of HCl·Asp(OBzl)-Gly-OBzl

[0031] 11.04g (23.50mmol) Boc-Asp(OBzl)-Gly-OBzl was dissolved in 250ml of 4mol / l hydrogen chloride-ethyl acetate solution, stirred at room temperature for 2 hours, TLC (chloroform: methanol, 5:1) showed that the starting material point disappeared , Concentrate under reduced pressure to remove ethyl acetate, and add a small amount of ether to the residue repeatedly and concentrate under reduced pressure to remove hydrogen chloride. Finally, a small amount of ether was added to grind the residue into 9.17 g (96%) of the title compound, which was a colorless solid powder, which was directly used in the next reaction. ESI-MS(m / z): 371[M+H] + .

Embodiment 3

[0032] Example 3 Preparation of Boc-Glu(OBzl)-Asp(OBzl)-Gly-OBzl

[0033] According to the method of Example 1, from 7.61 g (22.56 mmol) Boc-Glu (OBzl) and 9.17 g (22.56 mmol) HCl·Asp(OBzl)-Gly-OBzl, a beige oil was obtained. The obtained compound was purified by silica gel column chromatography to obtain 10.73 g of a colorless oily target. Purification conditions: chloroform:methanol=100:1, and the yield was 69%. ESI-MS(m / z): 690[M+H] + , [Α] 20 D =-24.4(c=1.0, CH 3 OH).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com