Centralized multi-connected cold (heat) source central air conditioning system

A technology for central air-conditioning systems and central air-conditioning units, applied in air-conditioning systems, ventilation systems, heating and ventilation control systems, etc., can solve the problems of difficult installation and maintenance, low safety, and high transmission loss, and reduce installation and maintenance costs. , the effect of eliminating energy consumption and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

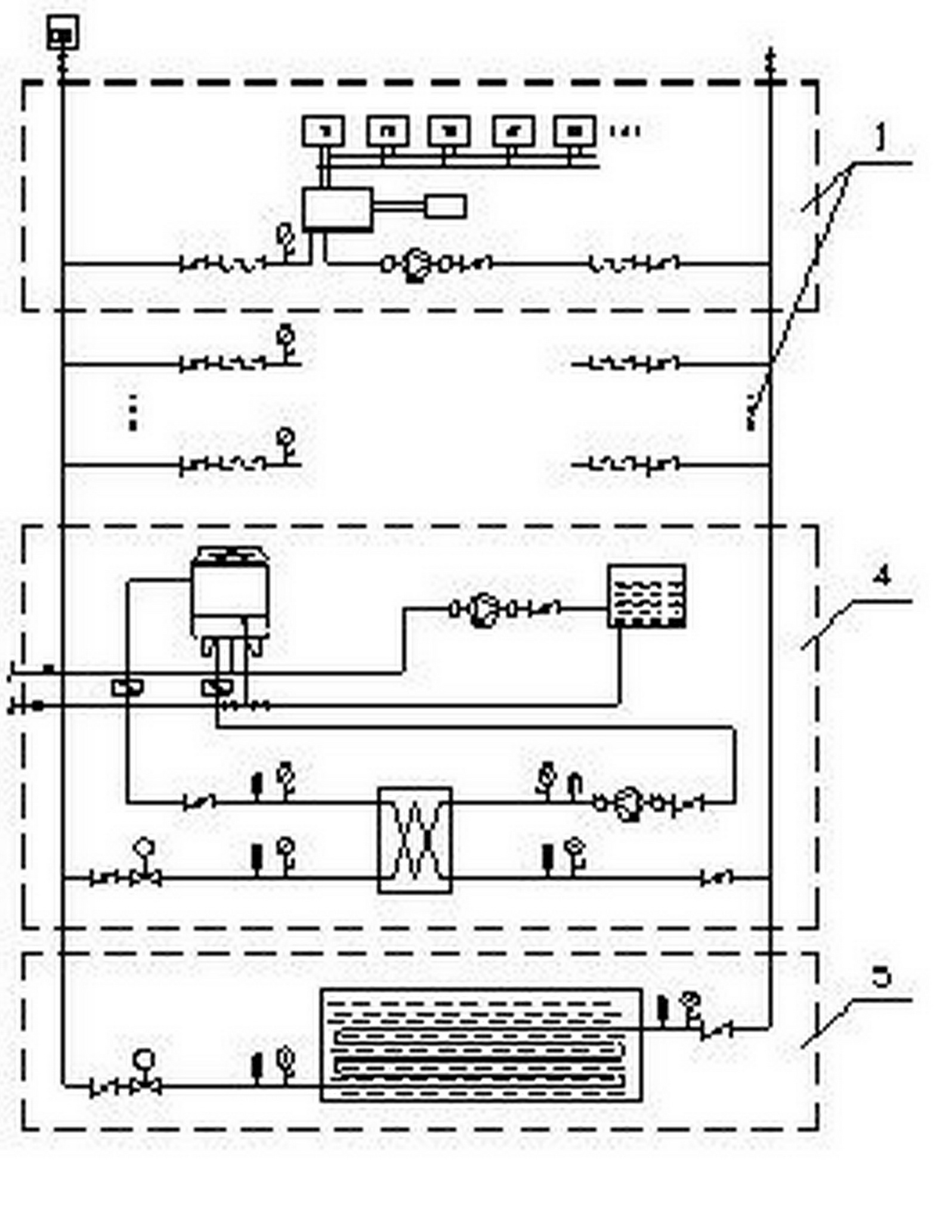

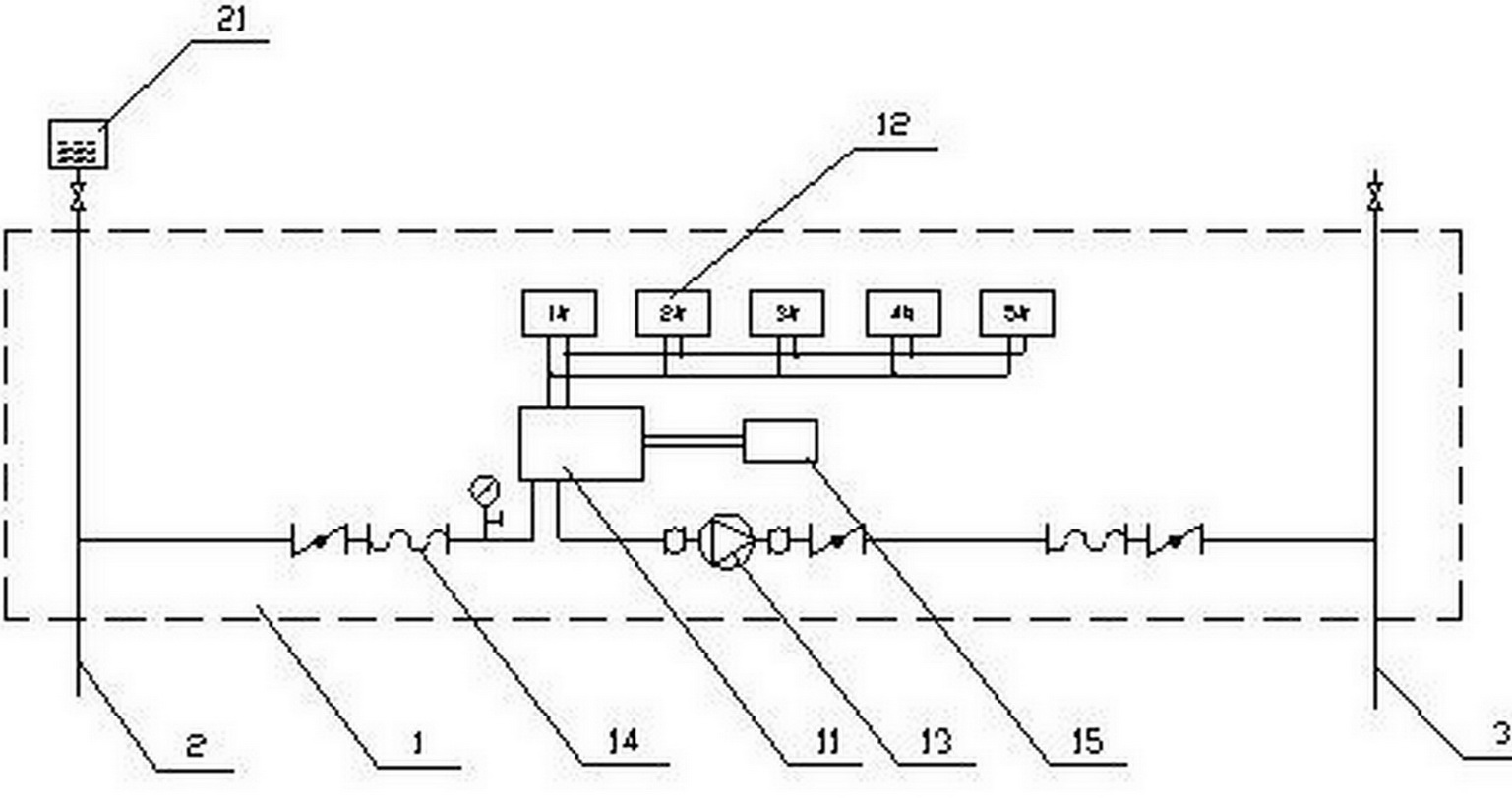

[0042] Embodiment 1: The centralized multi-connected cold (heat) source central air-conditioning system of this embodiment, such as figure 1 as shown,

[0043] Including central air-conditioning device, cold and heat source system and circulation piping system, circulation piping system includes water inlet main pipe 2 and water outlet main pipe 3, water inlet main pipe and water outlet main pipe are respectively connected with central air conditioning device and cold and heat source system, circulation pipe system An expansion tank 21 is installed on the top, and the heat exchange medium in the circulating piping system is antifreeze, and the piping system is also designed with a solution concentration automatic control device, which can monitor and control the concentration of antifreezing liquid in real time; the central air-conditioning device includes central air-conditioning in five areas Machine 1, such as figure 2 As shown, the central air conditioner is a water-cool...

Embodiment 2

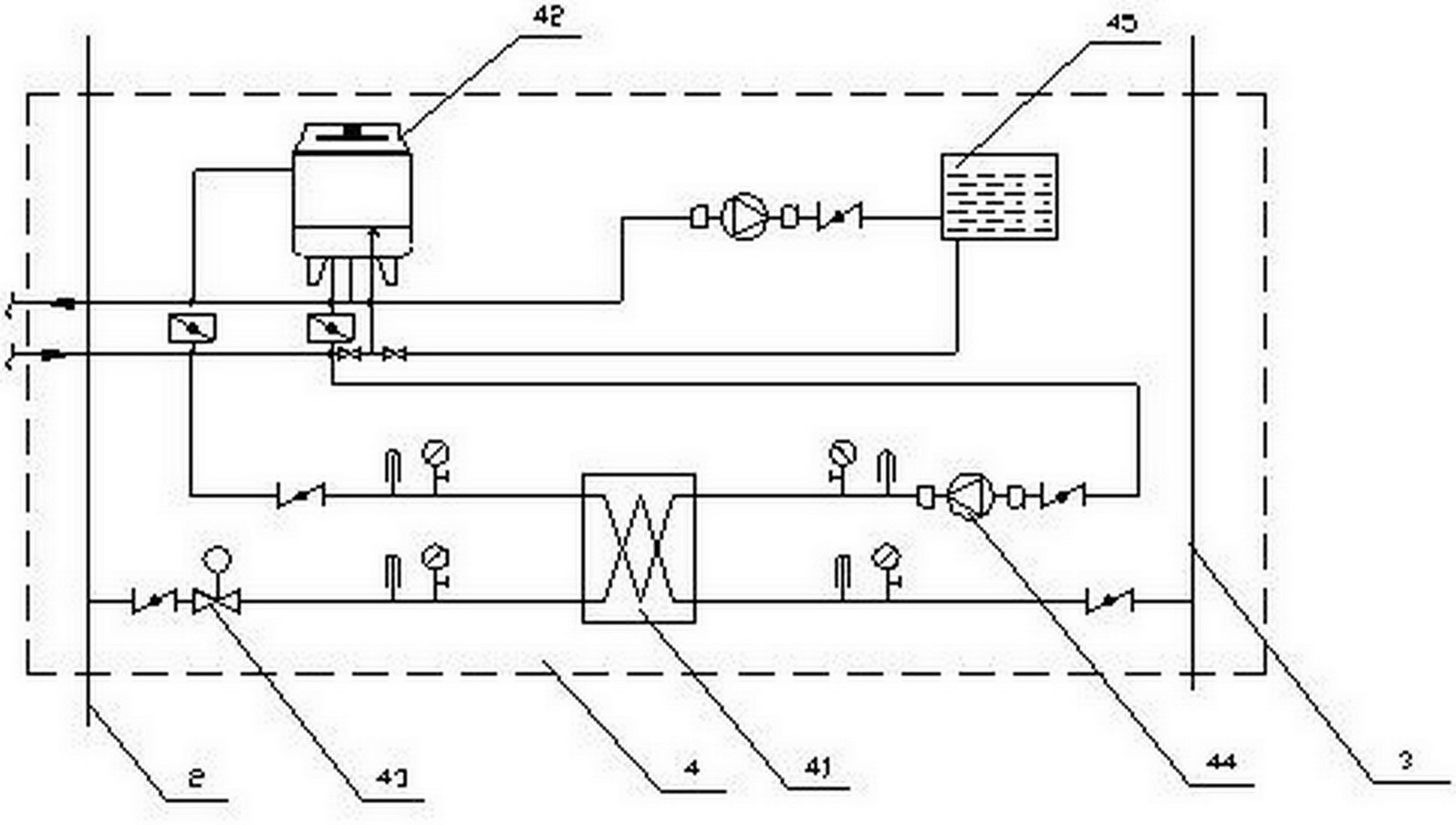

[0053]Embodiment 2: The centralized multi-connected cold (heat) source central air-conditioning system of this embodiment, such as Figure 5 with Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that the cold and heat sources of the central air-conditioning system are different. The cold and heat sources in Embodiment 1 are the waste water heat exchange system 5 and the air source heat exchange system 4. This implementation The cold and heat sources of the example are the ground source heat exchange system 6 and the air source heat exchange system 4, the two heat exchange systems are connected in parallel and connected with the circulation pipeline, the ground source heat exchange system includes the buried pipe heat exchanger 61, the ground source temperature difference The electric valve 62 and the connecting pipeline, the connecting pipeline includes a water inlet pipe and a water outlet pipe, the water inlet pipe is connected with the water in...

Embodiment 3

[0054] Embodiment 3: The centralized multi-connected cold (heat) source central air-conditioning system of this embodiment, such as Image 6 with Figure 8 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the number of cold and heat sources is increased. The cold and heat sources of this embodiment are waste water heat exchange system 5, ground source heat exchange system 6, water source The heat exchange system 7 and the air source heat exchange system 4 are all connected in parallel with each other and connected to the circulation pipeline. The order in which the cold and heat sources are put into operation in this embodiment is: firstly, the waste water heat exchange system, followed by the ground source The heat exchange system is followed by the water source heat exchange system, and finally the air source heat exchange system. The water source heat exchange system in this embodiment includes a water source heat exchanger 71, a wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com