Reciprocating type heat radiation air-preheating energy-saving fire grate

A technology of air preheating and heat radiation, applied in the field of grate, can solve the problems of large heat radiation loss, rising combustion temperature, easy corrosion and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

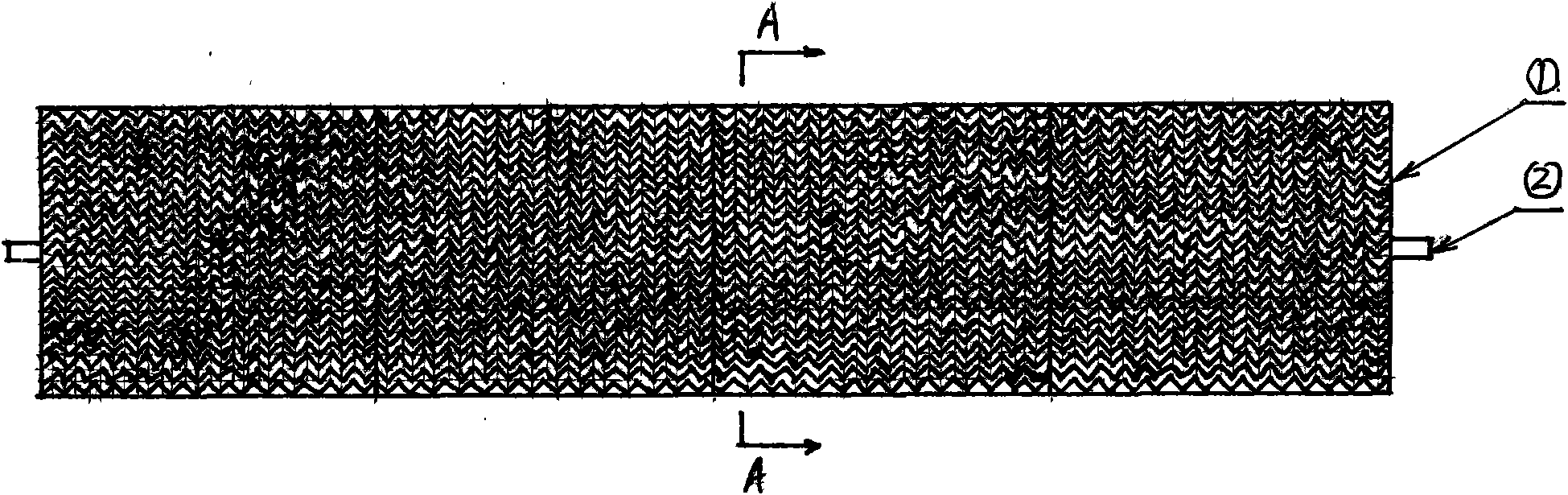

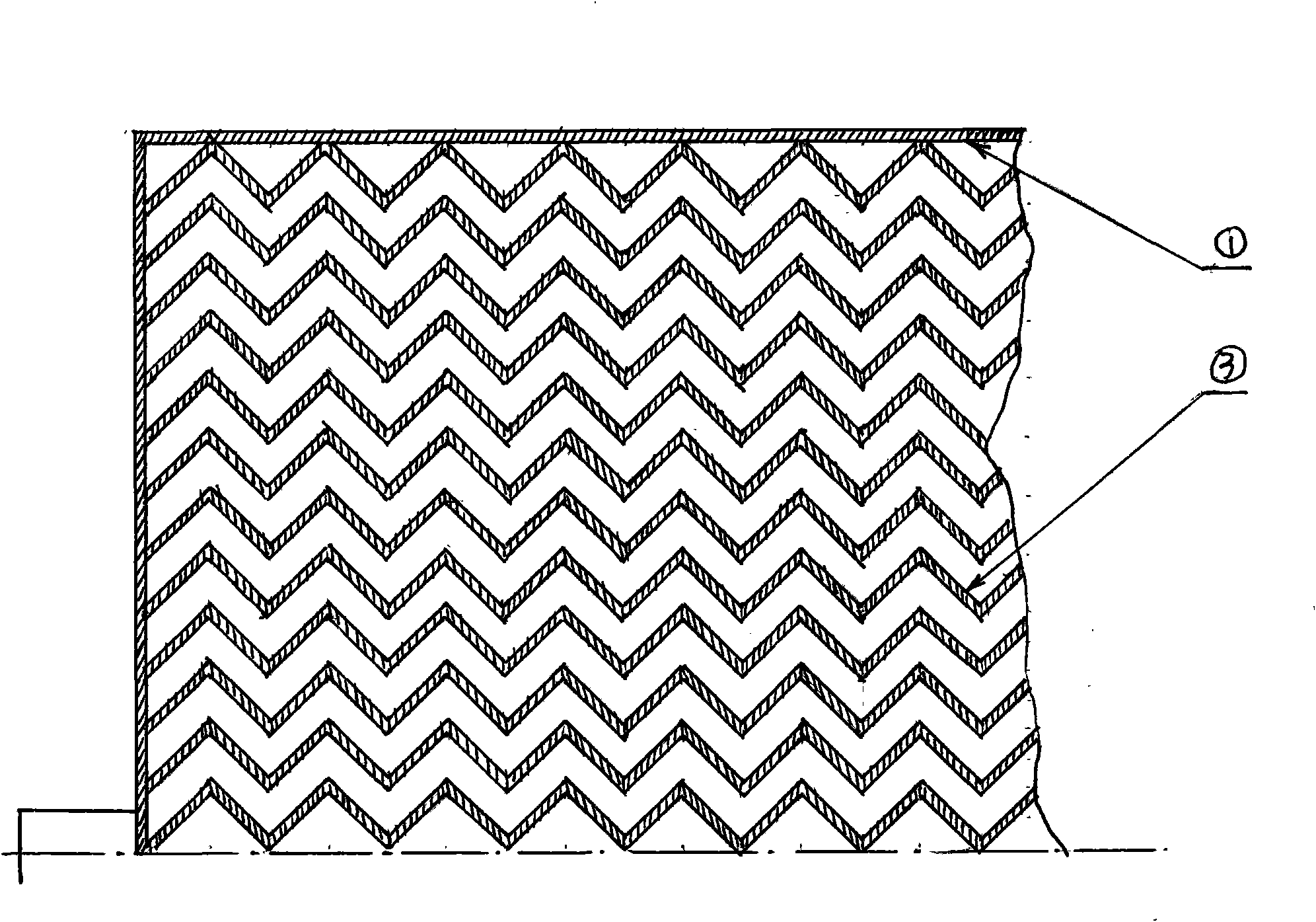

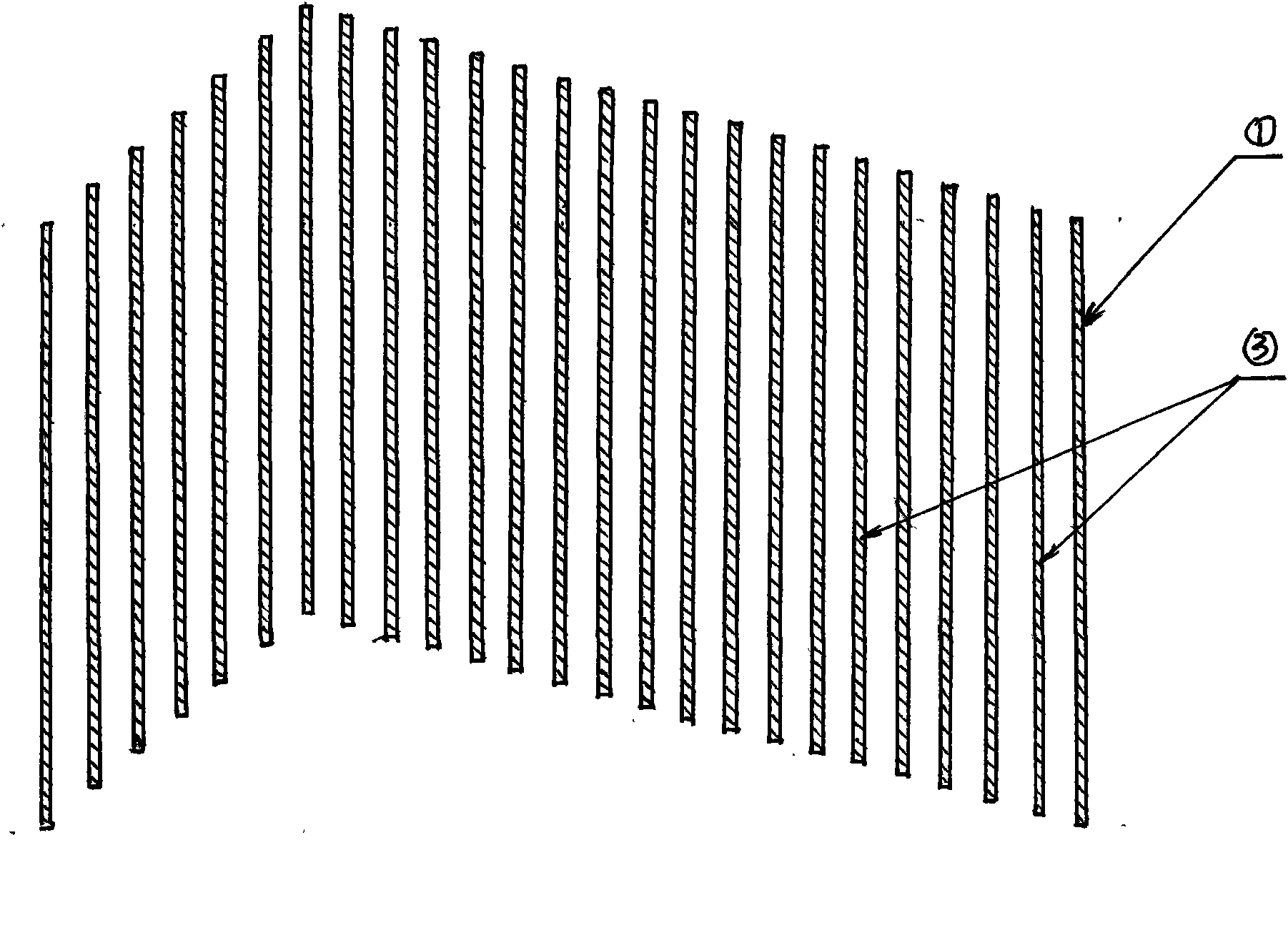

[0072] Example 1: In figure 1 In the square outer frame or frame 1, the corrugated slats 3 are erected equidistantly, and the support arms 2 are symmetrically installed outside the frame 1 to form a sub-grate; Figure 5 Among them, the support arm 2 on each sub-grate and the corresponding round hole 6 on the grate bracket 4 form a pair of rotary motion pairs, which can be partially rotated under the action of the push rod, so that the upper surface of the row bar can be used as a rotary motion. Reciprocating semi-arc movement, thereby stirring the fuel, several sub-grates form a grate.

Embodiment 2

[0073] Embodiment 2: The sub-grate structure remains unchanged. exist Figure 4 Among them, the round hole 6 on the grate support 4 is opened on the trapezoidal slider 7, and the grooves formed by the trapezoidal slider 7 and the vertical pair of trapezoidal retaining bars 5 form a pair of sliding kinematic pairs, and the slider 7 can be positioned at the top Under the action of the rod 8, it moves up and down. When the wedge 9 is pushed forward to the corresponding position, due to the action of the inclined plane of the wedge 9, the ejector rod 8 is pushed upward to the top dead center, so that the corresponding sub-grate rises to the top dead center, and the corresponding Due to the lack of support of the wedge 9, the adjacent sub-grate falls to the bottom dead center under the action of its own gravity or spring force. In this way, the adjacent sub-grate forms a certain height difference. At this time, the push rod pushes the lower position. The lower part of the sub-grat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com