Process for preparing drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling

A drill bit mud bag and drilling fluid technology, applied in the field of oil drilling, can solve the problems of rapid increase in specific gravity, poor inhibition of drilling fluid, poor lubrication performance, etc., and achieve the effects of increasing the proportion of the mud cake, improving the quality of the mud cake, and improving the lubricity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1. Drilling fluid requirements for vertical well sections before sidetracking

[0031] Before sidetracking, block drilling fluid technical measures should be implemented, and the focus of drilling fluid work should be to prevent collapse of the entire well section and ensure wellbore rules. It is required that the average diameter expansion of the vertical well section be controlled within 10%, and the maximum diameter expansion be controlled within 15%.

[0032] 2. Conversion of drilling fluid:

[0033] Under normal downhole conditions in the vertical well section, polymer drilling fluid should be used as much as possible to drill through the slurry formation in the upper part of Shiqianfeng. Then it is completely transformed into a compound salt-free soil-phase drilling fluid system.

[0034] In the case of abnormal downhole conditions, 40 cubic meters of white clay mud must be used to clean the sand that has not been carried out of the wellbore during conversion, a...

Embodiment 2

[0058] Embodiment 2 is substantially the same as Embodiment 1, and difference is that the treatment agent addition formula of the drilling fluid of the present invention is to be formulated by the following mass ratios in step 2: clear water polymer protoplasm: PAC: QS -4:CMS:SMP:SFT-1:NaCL:WT-1=1000:2:30:20:2:1.5:50:20, performance control: density ρ=1.06-1.10g / cm 3 , funnel viscosity T=38-45s, API dehydration FL=4-6ml; Wherein clear water polymer stock is prepared by the following mass ratio by PAM, K-PAM component: PAM: K-PAM: clear water=1.5 :2:1000. The CMS that present embodiment 2 adopts is carboxymethyl starch CMS-1 type.

Embodiment 3

[0059] Embodiment 3 is substantially the same as embodiment 1, and difference is that the treatment agent addition formula of drilling fluid of the present invention is to be prepared by following components by following mass ratio in step 2: clear water polymer former slurry: PAC: QS -4:CMS:SMP:SFT-1:NaCL:WT-1 is 1000:3:40:30:3:2:100:20, performance control: density ρ is 1.06-1.10g / cm 3 , funnel viscosity T=38-45s, API dehydration FL=4-6ml; Wherein clear water polymer stock is prepared by the following mass ratio by PAM, K-PAM component: PAM: K-PAM: clear water=2.5 :3:1000. The CMS that present embodiment 3 adopts is carboxymethyl starch CMS-1 type.

[0060] In the above-mentioned embodiment, CMS is not limited to carboxymethyl starch CMS-1 type, it can also be carboxymethyl starch CMS-2 type, carboxymethyl starch CMS-3 type and other specification models. The reagents in the formulas of the above examples were all purchased from the Equipment Company of Changqing Drilling ...

PUM

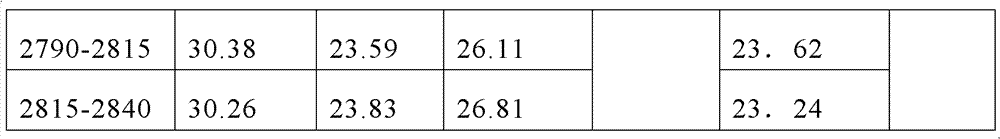

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com