Method for preparing high-temperature-resistant BPO4-ABPBI nanometer composite proton exchange membrane for fuel cell

A BPO4-ABPBI, proton exchange membrane technology, used in fuel cell parts, fuel cells, battery pack parts, etc., can solve the problems of PEMFC performance degradation, easy loss, and proton exchange membrane proton conductivity. The effect of good proton conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

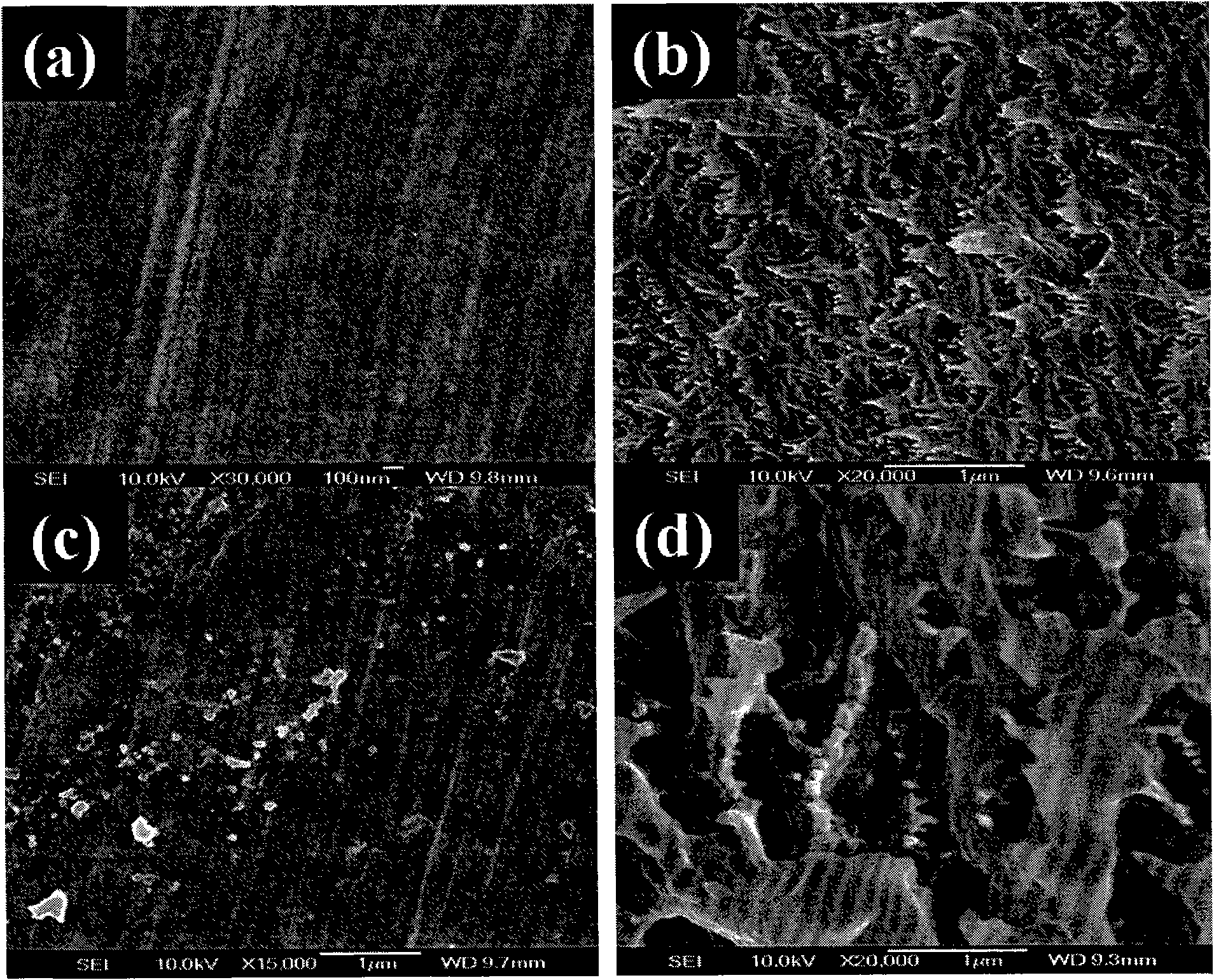

[0022] Example 1: High temperature resistant BPO 4 -Preparation of ABPBI nanocomposite proton exchange membrane

[0023] (1) Weigh 34.0g ABPBI solution, add 0.30g BPO 4 and dispersant (PEG / SDBS / TBAB), grind for 2 hours to obtain nano-dispersion system;

[0024] (2) Stand still at about 80°C for 30 minutes to make the bubbles in the nano-dispersion system disappear;

[0025] (3) Pour the nano-dispersion system obtained in (2) onto a clean glass plate while it is hot, and quickly scrape it evenly with a wet film preparation device to obtain a wet film;

[0026] (4) Immerse the glass plate together with the wet film in deionized water. After about 30 seconds, the yellow translucent film falls off automatically, and the original acidic film is obtained;

[0027] (5) Pull out the acidic original film, put into 10% NaOH solution or dilute ammonia water and soak for 24 hours, remove acidic substances such as methanesulfonic acid contained in the acidic original film, and obtain t...

Embodiment 2

[0031] Example 2: High temperature resistant BPO 4 -Preparation of ABPBI nanocomposite proton exchange membrane

[0032] (1) Weigh 34.0g ABPBI solution, add 0.20g BPO 4 and dispersant (PEG / SDBS / TBAB), grind for 2 hours to obtain nano-dispersion system;

[0033] (2) Stand still at about 80°C for 30 minutes to make the bubbles in the nano-dispersion system disappear;

[0034] (3) Pour the nano-dispersion system obtained in (2) onto a clean glass plate while it is hot, and quickly scrape it evenly with a wet film preparation device to obtain a wet film;

[0035] (4) Immerse the glass plate together with the wet film in deionized water. After about 30 seconds, the yellow translucent film falls off automatically, and the original acidic film is obtained;

[0036] (5) Pull out the acidic original film, put into 10% NaOH solution or dilute ammonia water and soak for 24 hours, remove acidic substances such as methanesulfonic acid contained in the acidic original film, and obtain t...

Embodiment 3

[0040] Example 3: High temperature resistant BPO 4 -Preparation of ABPBI nanocomposite proton exchange membrane

[0041] (1) Weigh 34.0g ABPBI solution, add 0.10g BPO 4 and dispersant (PEG / SDBS / TBAB), grind for 2 hours to obtain nano-dispersion system;

[0042] (2) Stand still at about 80°C for 30 minutes to make the bubbles in the nano-dispersion system disappear;

[0043] (3) Pour the nano-dispersion system obtained in (2) onto a clean glass plate while it is hot, and quickly scrape it evenly with a wet film preparation device to obtain a wet film;

[0044] (4) Immerse the glass plate together with the wet film in deionized water. After about 30 seconds, the yellow translucent film falls off automatically, and the original acidic film is obtained;

[0045] (5) Pull out the acidic original film, put into 10% NaOH solution or dilute ammonia water and soak for 24 hours, remove acidic substances such as methanesulfonic acid contained in the acidic original film, and obtain t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com