Method for preparing polypropylene composition and polypropylene composition

A technology of polypropylene composition and propylene copolymer, which is applied in the field of polyolefin materials, can solve the problems of cumbersome polymerization process, large energy consumption, and high equipment requirements, and achieve the effects of easy industrialization, low energy consumption, and low equipment requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

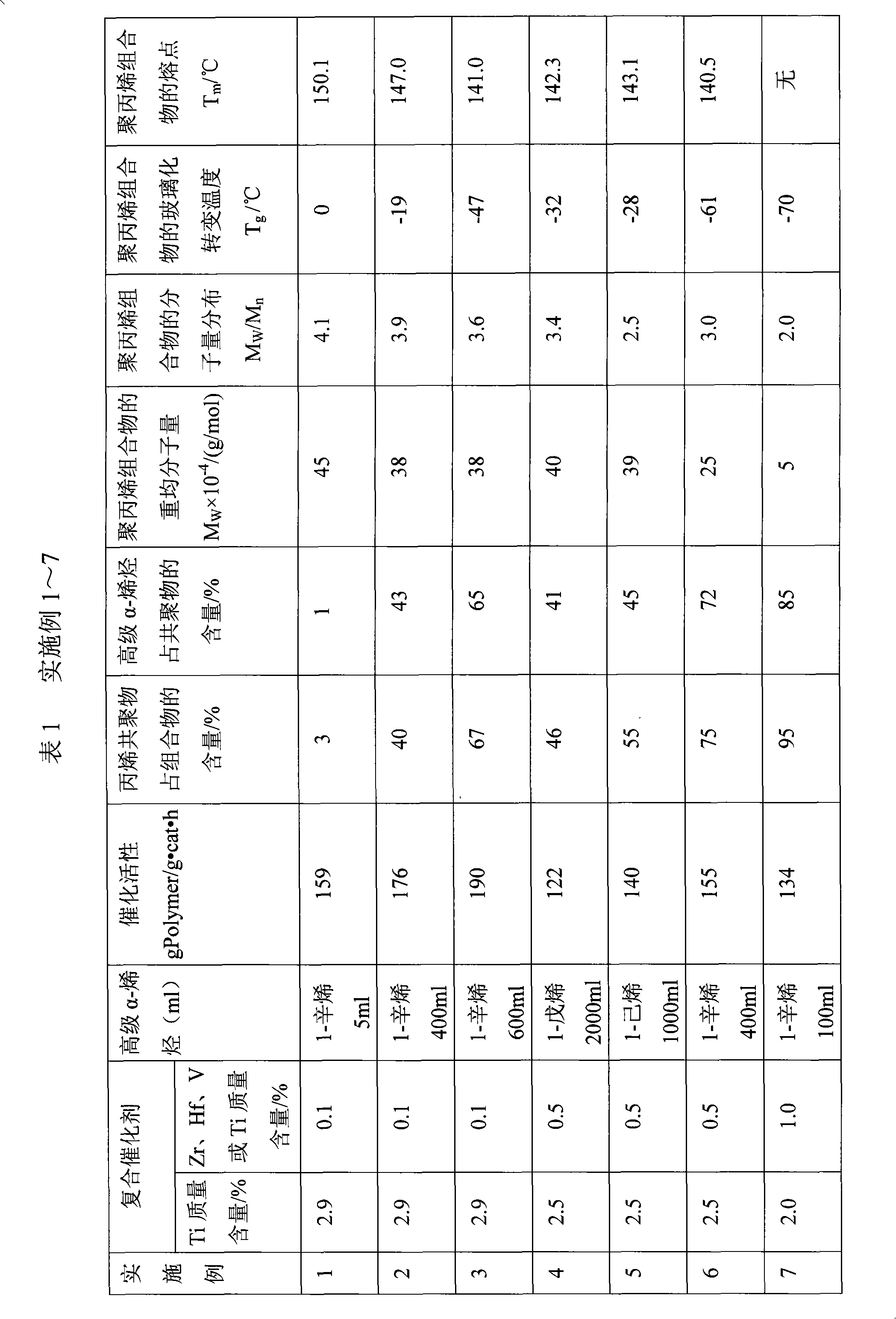

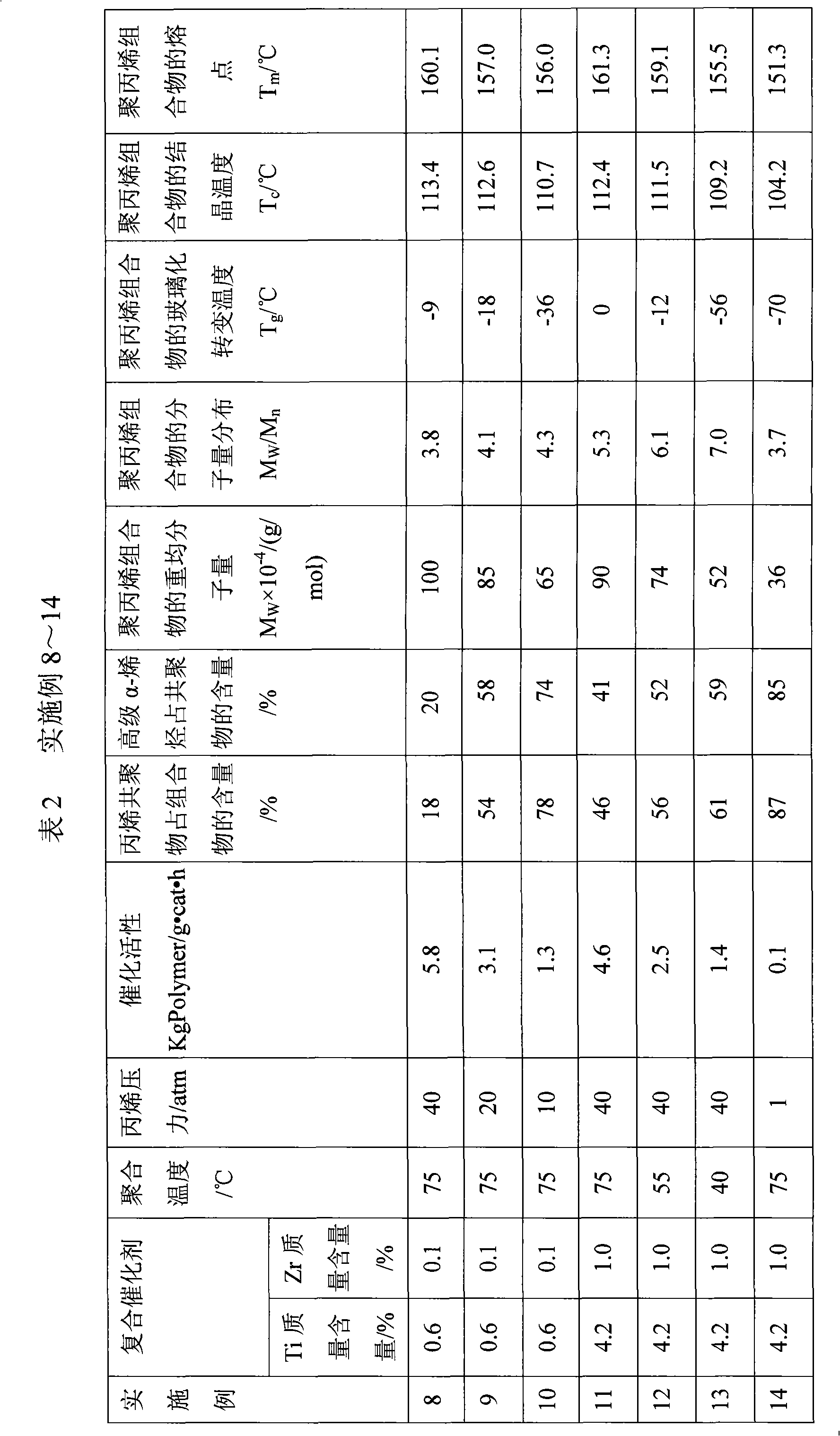

Examples

Embodiment 1

[0043] With 0.05g composite catalyst (composite catalyst is made of heterogeneous Ziegler-Natta catalyst with spherical shape and metallocene compound Me 2 Si(Ind) 2 ZrCl 2 The composite catalyst (Me is methyl, Ind is indenyl) that forms; Me 2 Si(Ind) 2 ZrCl 2 The Zr element in the composite catalyst accounts for 0.1% of the total mass of the composite catalyst; the heterogeneous Ziegler-Natta catalyst is based on MgCl 2 Carrier containing TiCl 4 and diisobutyl phthalate catalysts with spherical morphology, where TiCl 4 The Ti element in the catalyst accounts for 2.9% of the total mass of the composite catalyst, the Ti element accounts for 3.4% of the total mass of the Ziegler-Natta catalyst, and diisobutyl phthalate accounts for 0.5% of the total mass of the Ziegler-Natta catalyst) to join 500ml In the reaction kettle, add 0.06mol of MAO, 5ml of 1-octene, 0.1L of anhydrous n-heptane, at 40°C, feed in 1 atm of propylene, react for 0.5 hours, stop the reaction with 100ml ...

Embodiment 2

[0045] Under the atmosphere of propylene monomer, 1g composite catalyst (composite catalyst is made of heterogeneous phase Ziegler-Natta catalyst with spherical morphology and metallocene compound Me 2 Si(2-Me-4-Ph-Ind) 2 ZrCl 2 The composite catalyst formed (Ph is phenyl); Me 2 Si(2-Me-4-Ph-Ind) 2 ZrCl 2 The Zr element in the composite catalyst accounts for 0.1% of the total mass of the composite catalyst; the heterogeneous Ziegler-Natta catalyst is based on MgBr 2 Carrier containing TiBr 4 and diethyl succinate catalysts with spherical morphology, where TiBr 4 The Ti element in the catalyst accounts for 2.9% of the total mass of the composite catalyst, the Ti element accounts for 3.6% of the total mass of the Ziegler-Natta catalyst, and diethyl succinate accounts for 1% of the total mass of the Ziegler-Natta catalyst), 4L anhydrous Add heptane to the reactor, add 400ml 1-octene, 0.5mol MAO, and 0.5mol dimethoxydiphenylsilane in sequence, the pressure of the propylene m...

Embodiment 3

[0047] Operation is the same as in Example 2, except that the amount of 1-octene added is 600ml. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com