Flocculating agent for cement high pressure jet grouting and preparation method and application thereof

A high-pressure jetting and flocculant technology is applied in the field of high-pressure jet grouting for cement and its preparation field. low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

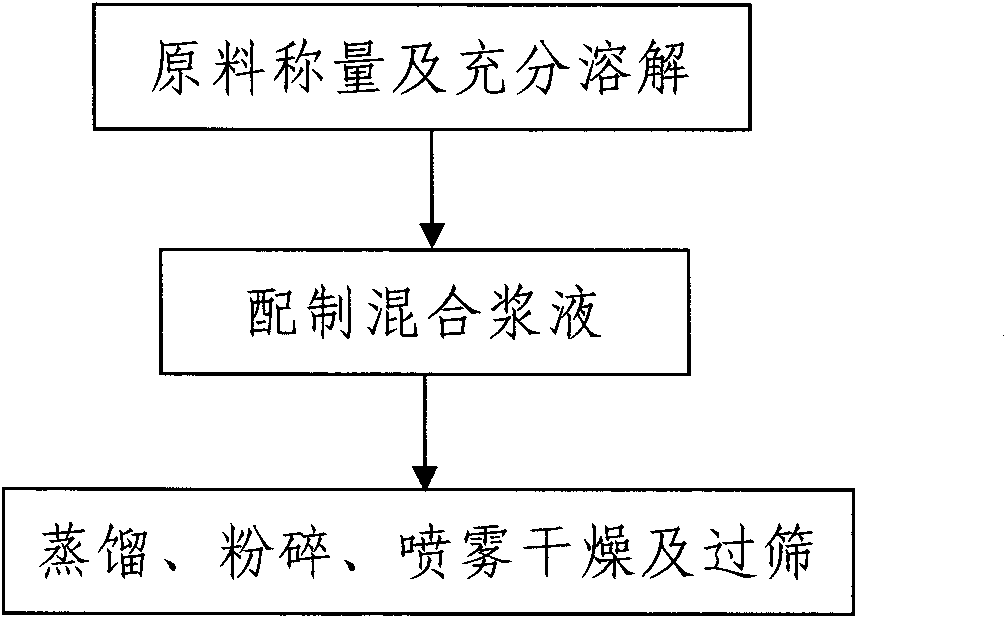

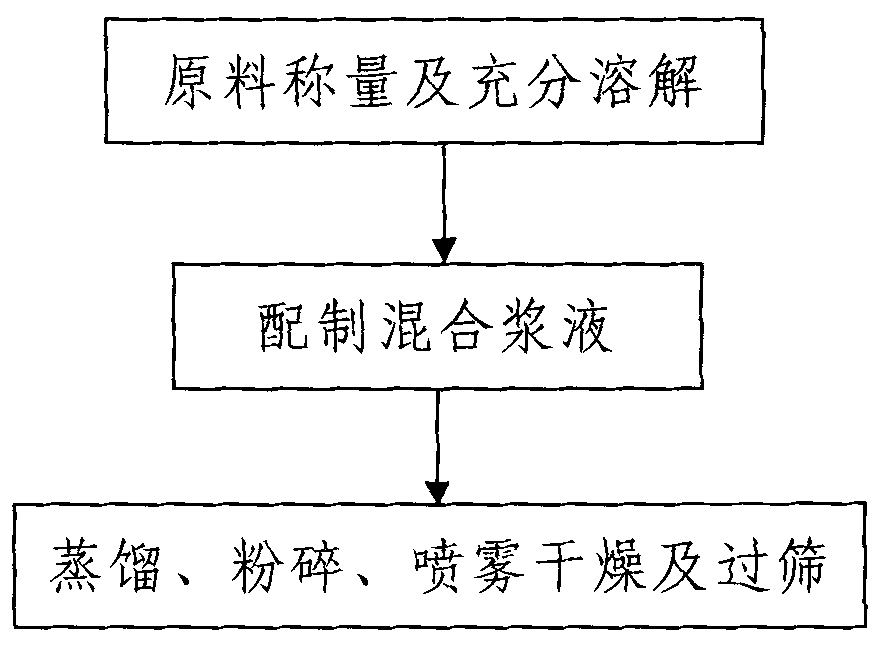

[0031] Such as figure 1 A kind of preparation method of flocculant for cement high-pressure jet grouting shown, comprises the following steps:

[0032] Step 1. Raw material weighing and fully dissolving: first weigh the five raw materials of konjac glucomannan (KGM), carbonate, rheological agent, dispersant and early strength agent according to the designed ratio; After adding water to the five raw materials and fully dissolving them respectively, konjac glucomannan solution, carbonate solution, rheological agent solution, dispersant solution and early strength agent solution were prepared accordingly;

[0033] Step 2. Prepare mixed slurry: Pour the konjac glucomannan solution, carbonate solution, rheological agent solution, dispersant solution and early strength agent solution into the container at the same time as described in step 1, and stir evenly to obtain a mixed slurry ;

[0034]Step 3, distillation, pulverization, spray drying and sieving: put the mixed slurry in st...

Embodiment 1

[0041] In this embodiment, when preparing the flocculant for cement high-pressure jet grouting, first weigh out 4.0kg konjac glucomannan, 2.5kg sodium carbonate, 1.0kg rheological agent, 1.5kg dispersant and 1.0kg early strength agent; Then put five kinds of raw materials weighed out and water (the amount of water added is determined according to the quality of the five kinds of raw materials and their respective solubility respectively) into plastics, glass or enamel containers and fully mixed and stirred evenly. Carry out fully dissolving, and respectively make corresponding quality and fully dissolved konjac glucomannan solution, carbonate solution, rheology agent solution, dispersant solution and early strengthening agent solution; Then, again described konjac glucomannan The polysaccharide solution, the carbonate solution, the rheological agent solution, the dispersant solution and the early strength agent solution are respectively put into plastic, glass or enamel contain...

Embodiment 2

[0045] In this example, when preparing the flocculant for cement high-pressure jet grouting, the difference from Example 1 is: first weigh out 4.5kg of konjac glucomannan, 2.8kg of sodium carbonate, 1.2kg of rheological agent, and 1.7kg of dispersant agent and 1.2kg early-strength agent; then put the weighed five kinds of raw materials and water (the amount of water added is determined according to the quality of the five kinds of raw materials and their respective solubility) respectively into plastic, glass or enamel containers for full mixing Stir evenly, above-mentioned five kinds of raw materials are fully dissolved, and respectively make corresponding quality and fully dissolved konjac glucomannan solution, carbonate solution, rheology agent solution, dispersant solution and early strength agent solution; , and then the konjac glucomannan solution, carbonate solution, rheological agent solution, dispersant solution and early strength agent solution are respectively simult...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com