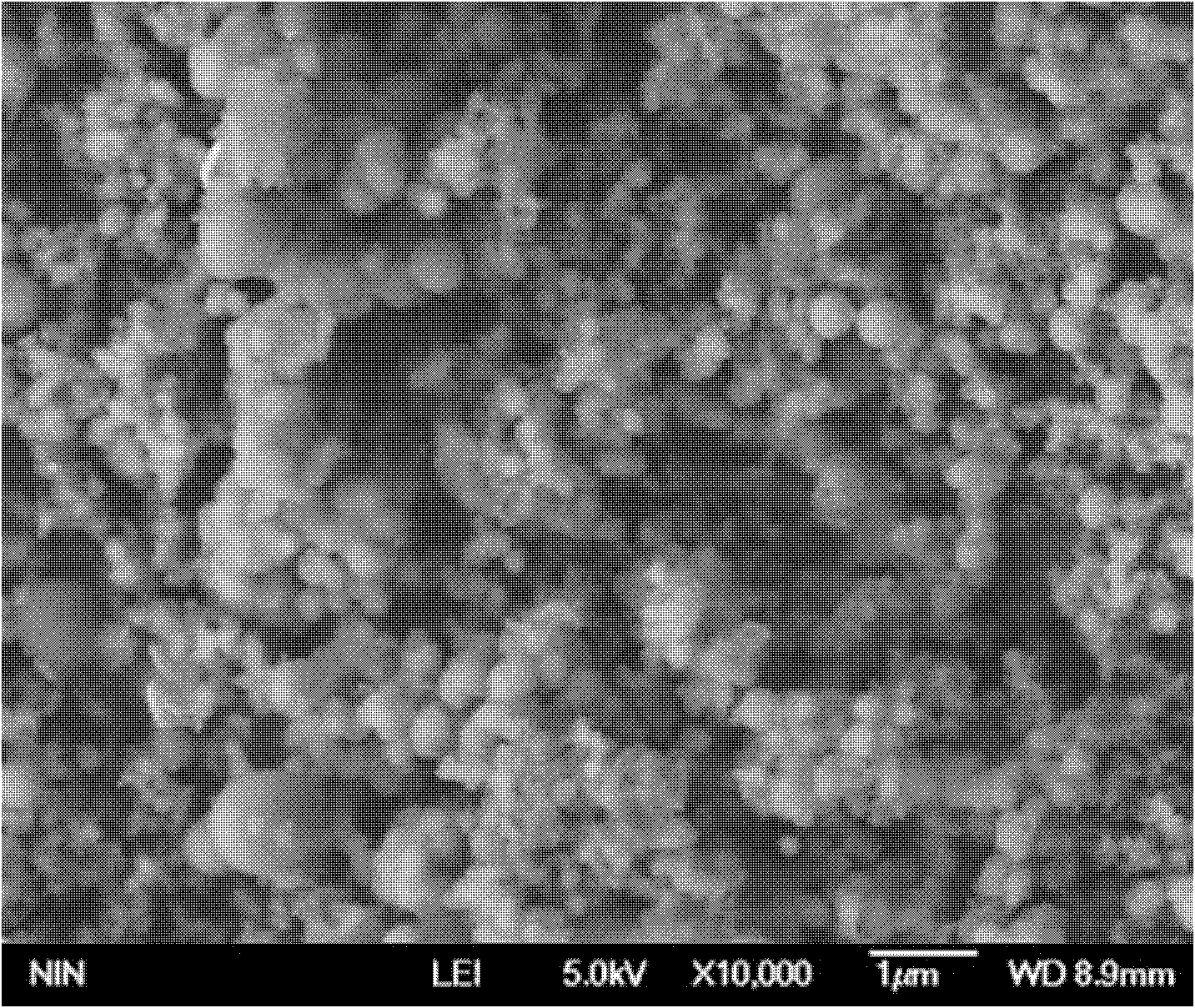

Method for preparing TiO2/SiO2 composite microspheres

A technology of composite microspheres and ammonia water, applied in the field of nanomaterials, can solve the problems of high processing temperature, low utilization rate of sunlight, and many impurities, and achieves the effects of uniform particle size, shortened preparation period, and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A kind of TiO 2 / SiO 2 The preparation method of composite microsphere comprises the following steps:

[0023] 1) Dissolve 192.14g (1mol) of citric acid in 300ml of ammonia water with a volume concentration of 25%, then add 0.5mol of ethyl orthosilicate, stir to dissolve the ethyl orthosilicate; after dissolving, add 100ml in sequence Dehydrated ethanol and 64.05g of polyethylene glycol (PEG4000), heated to 50 ° C and stirred to completely dissolve; adjust the pH value to 7.0 with ammonia water to obtain Sol A;

[0024] 2) Dissolve 192.14g (1mol) of citric acid in 300ml of ammonia water with a volume concentration of 25%, then add 0.5mol of butyl titanate, stir to dissolve the butyl titanate; Water ethanol and 64.05g of polyethylene glycol (PEG4000), heated to 50°C and stirred to dissolve completely; adjusted the pH value to 7.0 with ammonia water, and evaporated in a water bath at 80°C until wet gel B was obtained;

[0025] 3) According to the molar ratio of Si:Ti=1...

Embodiment 2

[0029] A kind of TiO 2 / SiO 2 The preparation method of composite microsphere comprises the following steps:

[0030] 1) Dissolve 192.14g (1mol) of citric acid in 300ml of ammonia water with a volume concentration of 28%, then add 0.67mol of ethyl orthosilicate, stir to dissolve the ethyl orthosilicate; after dissolving, add 150ml in sequence Anhydrous ethanol and 96.07g of polyethylene glycol (PEG4000) were heated to 60°C and stirred to dissolve completely; the pH value was adjusted to 8.0 with ammonia water to obtain Sol A;

[0031] 2) Dissolve 192.14g (1mol) of citric acid in 300ml of ammonia water with a volume concentration of 28%, then add 0.67mol of butyl titanate, stir to dissolve the butyl titanate; Water ethanol and 96.07g of polyethylene glycol (PEG4000), heated to 60°C and stirred to dissolve completely; adjusted the pH value to 8.0 with ammonia water, and evaporated in a water bath at 90°C until wet gel B was obtained;

[0032] 3) According to the molar ratio o...

Embodiment 3

[0035] A kind of TiO 2 / SiO 2 The preparation method of composite microsphere comprises the following steps:

[0036]1) Dissolve 192.14g (1mol) of citric acid in 300ml of ammonia water with a volume concentration of 28%, then add 0.55mol of ethyl orthosilicate, stir to dissolve the ethyl orthosilicate; after dissolving, add 120ml in sequence Anhydrous ethanol and 85g of polyethylene glycol were heated to 56°C and stirred to dissolve completely; the pH value was adjusted to 7.5 with ammonia water to obtain Sol A;

[0037] 2) Dissolve 192.14g (1mol) of citric acid in 300ml of ammonia water with a volume concentration of 28%, then add 0.55mol of butyl titanate, stir to dissolve the butyl titanate; Water ethanol and 75g of polyethylene glycol, heated to 50°C and stirred to dissolve completely; adjust the pH value to 7.0 with ammonia water, and evaporate in a water bath at 90°C until wet gel B is obtained;

[0038] 3) According to the molar ratio of Si:Ti=1:6, sol A was added to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com