Preparation method of bio-ceramic coating titanium-wire sintering porous titanium artificial bone

A technology of ceramic coating and porous titanium, which is applied in the field of preparation in the field of biomedical engineering technology, can solve problems such as inability to overcome cracks, and achieve the effects of good biological activity and high mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

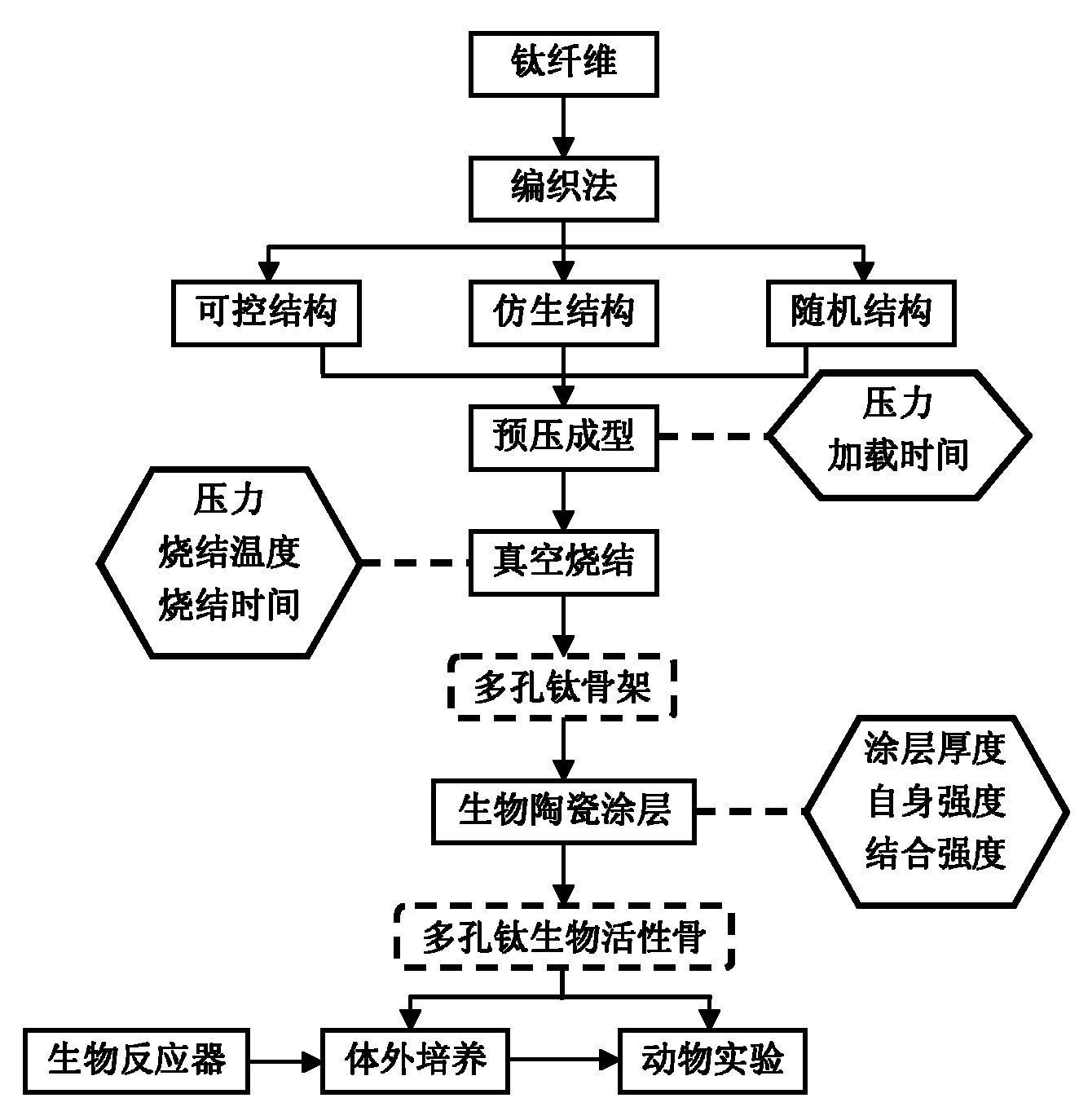

[0027] Such as figure 1As shown, the technological process of preparing porous titanium artificial bone by sintering titanium fiber three-dimensional weaving technology and preparing bioceramic coating on the surface of porous titanium artificial bone, using three-dimensional weaving method to construct an orthogonal porous structure titanium grid, a diameter of 0.2 mm titanium metal fiber wires are woven according to the orthogonal structure. Firstly, the titanium wires are woven horizontally into a uniform and parallel horizontal arrangement structure in a circular area with a diameter of 20 mm, and the distance between each arrangement is 1 mm. The wires shuttle and weave back and forth from the parallel lines just woven, and form a set of uniform and parallel arrangement structures in the longitudinal direction, with the same spacing of 1mm. The parallel arrangement structures of the horizontal and vertical titanium wires are vertically interlaced Together, on the basis of...

Embodiment 2

[0030] The three-dimensional weaving method is used to construct an orthogonal porous structure titanium grid, and a titanium metal fiber wire with a diameter of 0.6mm is woven according to the orthogonal structure. , a parallel arrangement structure, the distance between each arrangement is 0.5mm, and then the titanium wire is shuttled back and forth from the parallel line just woven along the longitudinal direction, forming a group of uniform and parallel arrangement structures in the longitudinal direction. The spacing is also 0.5mm, and the horizontal and vertical titanium wires are arranged in parallel and interlaced vertically. On the basis of this layer, weave the second layer according to the same method and steps until a porous titanium wire with a height of 30mm is formed. The wire mesh frame structure is then placed in the mold, and a load of 200MPa is applied for pre-compression molding, and the loading time is maintained for 10 minutes, so that the titanium metal f...

Embodiment 3

[0033] The three-dimensional weaving method is used to construct an orthogonal porous structure titanium grid. A titanium metal fiber wire with a diameter of 0.4mm is woven according to the orthogonal structure. First, the titanium wire is woven horizontally in a circular area with a diameter of 10mm , parallel arrangement structure, the distance between each arrangement is 1.5mm, and then weave the titanium wire back and forth from the parallel lines just woven along the longitudinal direction, and form a group of uniform and parallel arrangement structures in the longitudinal direction. The spacing is also 1.5mm, and the horizontal and vertical titanium wires are arranged in parallel and vertically interlaced with each other. On the basis of this layer, weave the second layer according to the same method and steps until a porous titanium with a height of 20mm is formed. The wire mesh frame structure is then placed in the mold, and a load of 80MPa is applied for pre-compressio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com