Polycarbonate modified material used in sunshade board of LED lamp and preparation method thereof

A technology of polycarbonate and LED lamps, which is applied in the field of polymer materials, can solve problems such as not suitable for LED lamp shades, and achieve the effect of dimensional stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

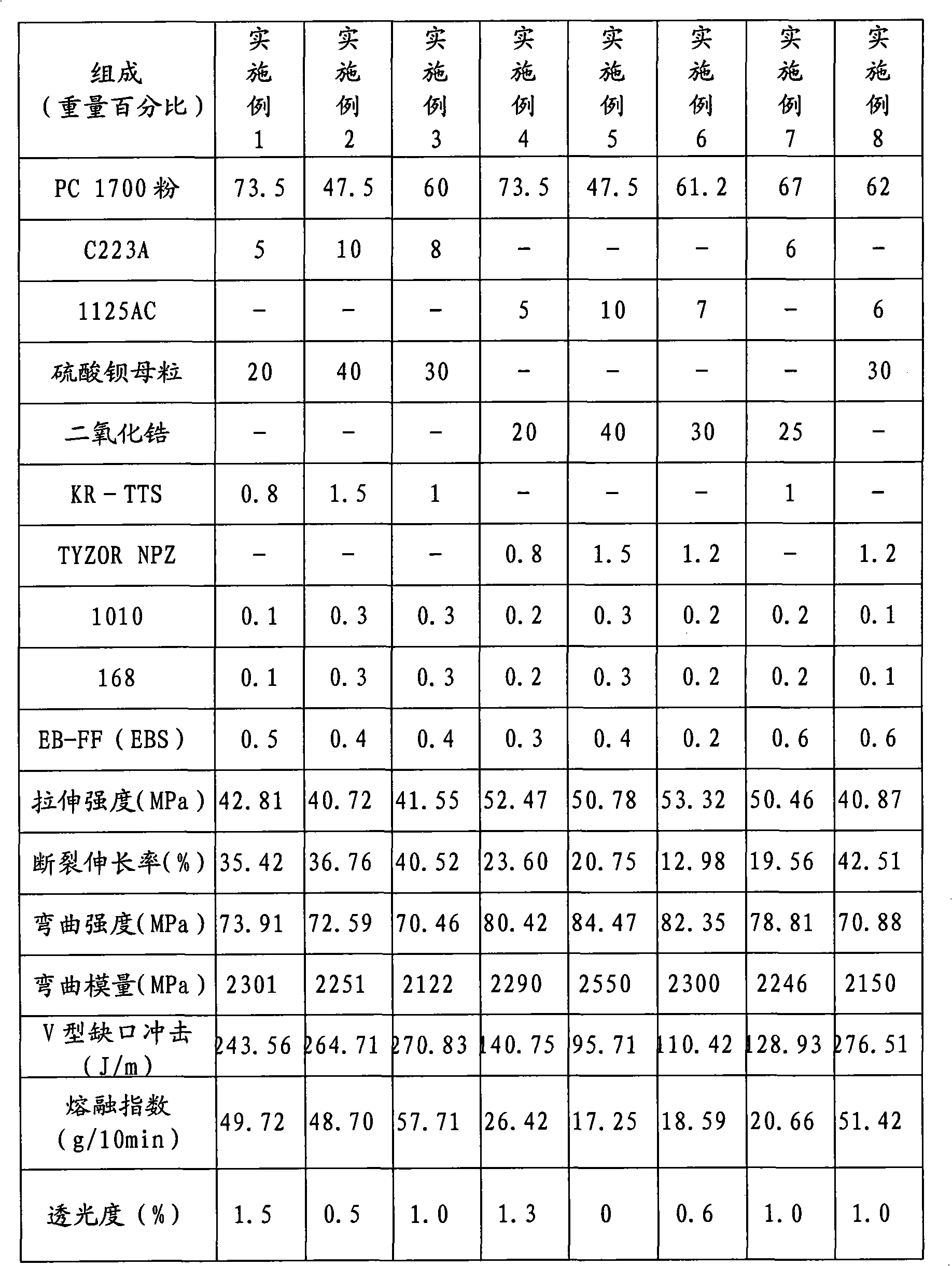

Embodiment 1

[0040] Components and content: polycarbonate 1700 powder 73.5%, impact modifier C223A 5%, filler barium sulfate masterbatch 20%, surface treatment agent KR-TTS 0.8%, compound antioxidant 1076 0.1% 168 0.1% , Processing aid EBS 0.5%.

[0041] First put the filler in an oven at 90-100 degrees and bake for 6 hours to remove moisture; then put it into a high-speed mixer and mix it with surface treatment agent at high speed, the mixing speed is 600r / min, the mixing temperature is 70-90℃, and mix for 15 minutes stand-by;

[0042] Then add the baked polycarbonate resin (drying condition: 120 degrees for 4 hours), impact modifier, antioxidant and processing aid to the high mixer and mix for 15 minutes;

[0043] The mixed raw materials are melted and extruded by a twin-screw extruder, and granulated;

[0044] The twin-screw extruder process is as follows: the temperature of the first zone of the twin-screw extruder is 100°C, the temperature of the second zone is 160°C, the temperatur...

Embodiment 2

[0046] Components and content: polycarbonate 1700 powder 47.5%, impact modifier C223A 10%, filler barium sulfate masterbatch 40%, surface treatment agent KR-TTS 1.5%, compound antioxidant 1076 0.3% 168 0.3% , Processing aid EBS 0.4%.

[0047] All the other are with embodiment 1.

[0048]The twin-screw extruder process is as follows: the temperature of the first zone of the twin-screw extruder is 120°C, the temperature of the second zone is 160°C, the temperature of the third zone is 250°C, the temperature of the fourth zone is 245°C, the temperature of the fifth zone is 240°C, and the temperature of the sixth zone is 240°C. The temperature is 235°C, the temperature of the seventh zone is 235, the temperature of the eighth zone is 240, the temperature of the die head is 250, the screw speed is 420r / min, and the feeding speed of the main engine is 20r / min.

Embodiment 3

[0050] Components and content: polycarbonate 1700 powder 60%, impact modifier C223A 8%, filler barium sulfate masterbatch 30%, surface treatment agent KR-TTS 1%, compound antioxidant 1076 0.3% 1680.3%, Processing aid EBS 0.4%.

[0051] All the other are with embodiment 1.

[0052] The twin-screw extruder process is as follows: the temperature of the first zone of the twin-screw extruder is 110°C, the temperature of the second zone is 180°C, the temperature of the third zone is 235°C, the temperature of the fourth zone is 235°C, the temperature of the fifth zone is 230°C, and the temperature of the sixth zone is 230°C. The temperature is 230°C, the temperature of the seventh zone is 225, the temperature of the eighth zone is 235, the temperature of the die head is 240, the screw speed is 450r / min, and the feeding speed of the main engine is 30r / min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

| bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com