Method for manufacturing hammer shaft of single-stage hammer crusher

A manufacturing method, single-stage hammer-type technology, applied in the manufacturing field of crusher parts, can solve the problems of non-conformity with energy saving and environmental protection, inconsistent mechanical properties of parts core and surface, high scrap rate, etc., and achieve obvious economic and social benefits , Eliminate abnormal fracture and improve the tool life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

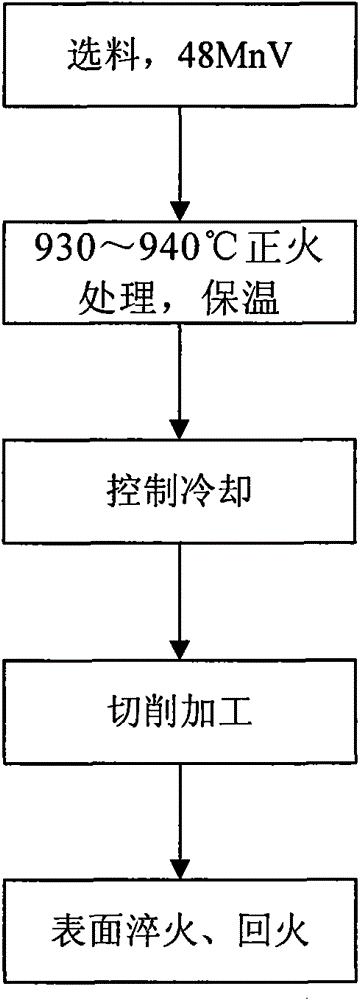

[0027] image 3 A method for manufacturing a hammer shaft of a single-stage hammer crusher according to the present invention is shown, and the method steps include:

[0028] a. Select hot-rolled 48MnV round steel;

[0029] b. Normalizing treatment at 930~940℃, holding time: 70~75 minutes;

[0030] c. Cooling, using air cooling; control the cooling speed, the cooling speed is controlled at 30-40 °C / min when the temperature is above 500 °C, and it can be air-cooled to room temperature when the temperature is below 500 °C;

[0031] d. Cutting and forming;

[0032] e. Surface induction hardening and tempering.

[0033] Surface induction hardening (intermediate frequency induction hardening, heating temperature 900°C, water cooling), tempering (200°C heating, heat preservation, air cooling). The above-mentioned surface induction hardening and tempering process is a conventional heat treatment process to ensure that the surface hardness of the quenched part is ≥52HRC; it is als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com