Manufacturing method for oblique rolling of bimetallic compound seamless steel pipe by centrifugal blank

A technology of a seamless steel pipe and a manufacturing method, which is applied in the manufacturing field, can solve the problems of low metal yield, high cost, and low yield, and achieve the effects of improving metal yield, refining grains, and reducing processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

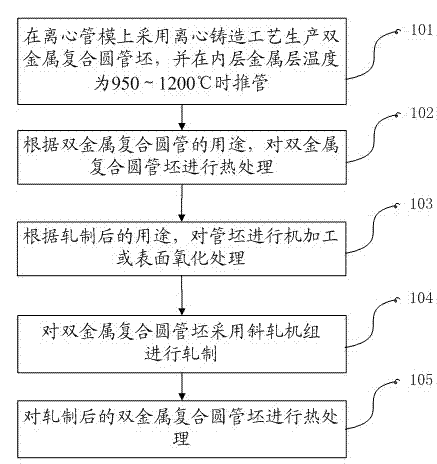

[0038] The first embodiment of the present invention proposes a method for manufacturing a centrifugal billet cross-rolled double-metal composite seamless steel pipe, the process of which is as follows figure 1 shown, including:

[0039] Step 101, using a centrifugal casting process on the centrifugal pipe mold to produce a bimetallic composite round pipe billet, and pushing the pipe when the temperature of the inner metal layer is 950-1400°C;

[0040] Step 102, performing heat treatment on the billet of the bimetal composite round tube according to the application of the bimetal composite round tube;

[0041] Step 103, performing machining or surface oxidation treatment on the tube billet according to the usage after rolling;

[0042] Step 104, rolling the bimetal composite round billet by a skew rolling mill;

[0043] Step 105, performing heat treatment on the rolled bimetallic composite round tube billet.

[0044] The manufacturing method of the centrifugal billet cross-...

no. 2 example

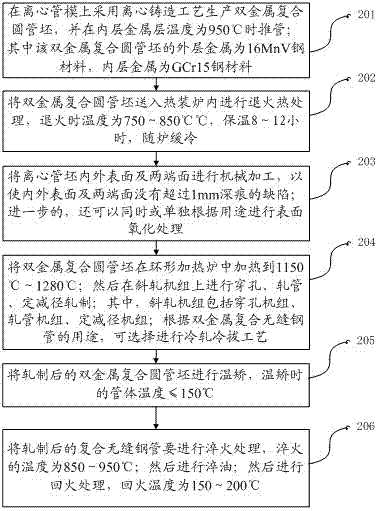

[0046] The second embodiment of the present invention proposes a method for manufacturing a centrifugal billet cross-rolled bimetal composite seamless steel pipe, which is used to manufacture a 16MnV and GCr15 centrifugal billet cross-rolled bimetal composite seamless steel pipe. The outer and inner thicknesses are 36.5mm and 18.5mm respectively, the diameter of the tube blank is 210mm, and the length is 2009mm. Process such as figure 2 shown, including:

[0047] Step 201: Produce a bimetallic composite round billet by adopting a centrifugal casting process on a centrifugal pipe mold, and push the pipe when the temperature of the inner metal layer is 950°C; wherein the outer metal of the bimetallic composite round billet is 16MnV steel material , the inner metal is GCr15 steel material;

[0048] Step 202, sending the bimetallic composite round tube billet into a hot charging furnace for annealing heat treatment, the temperature during annealing is 750-850°C, heat preservati...

no. 3 example

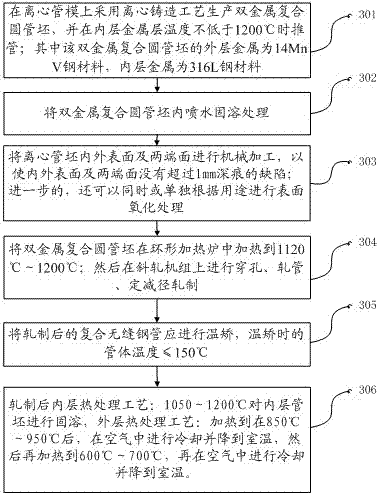

[0055] The third embodiment of the present invention also proposes a method for manufacturing 14MnV and 316L centrifugal billet cross-rolled bimetallic composite seamless steel pipes. The outer and inner thicknesses are 39mm and 14mm respectively, the diameter of the tube blank is 210mm, and the length is 1995mm. Process such as image 3 shown, including:

[0056] Step 301, using the centrifugal casting process on the centrifugal pipe mold to produce a bimetal composite round tube blank, and push the tube when the temperature of the inner metal layer is not lower than 1200°C; wherein the outer metal of the bimetal composite round tube blank is 14MnV Steel material, the inner metal is 316L steel material;

[0057] Step 302, spraying water into the bimetallic composite circular tube for solid solution treatment;

[0058] Step 303, machining the inner and outer surfaces and both ends of the centrifugal tube blank so that there are no defects exceeding 1mm deep marks on the inn...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com