Interface system method of mechanical property prediction of welding joint based on computer technology

A technology for performance prediction and welded joints, which is applied in the field of interface systems for prediction of mechanical properties of welded joints, can solve the problems of huge cost, delay in production, long cycle, etc., and achieve the effect of improving qualification rate, improving production efficiency, and comprehensive functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

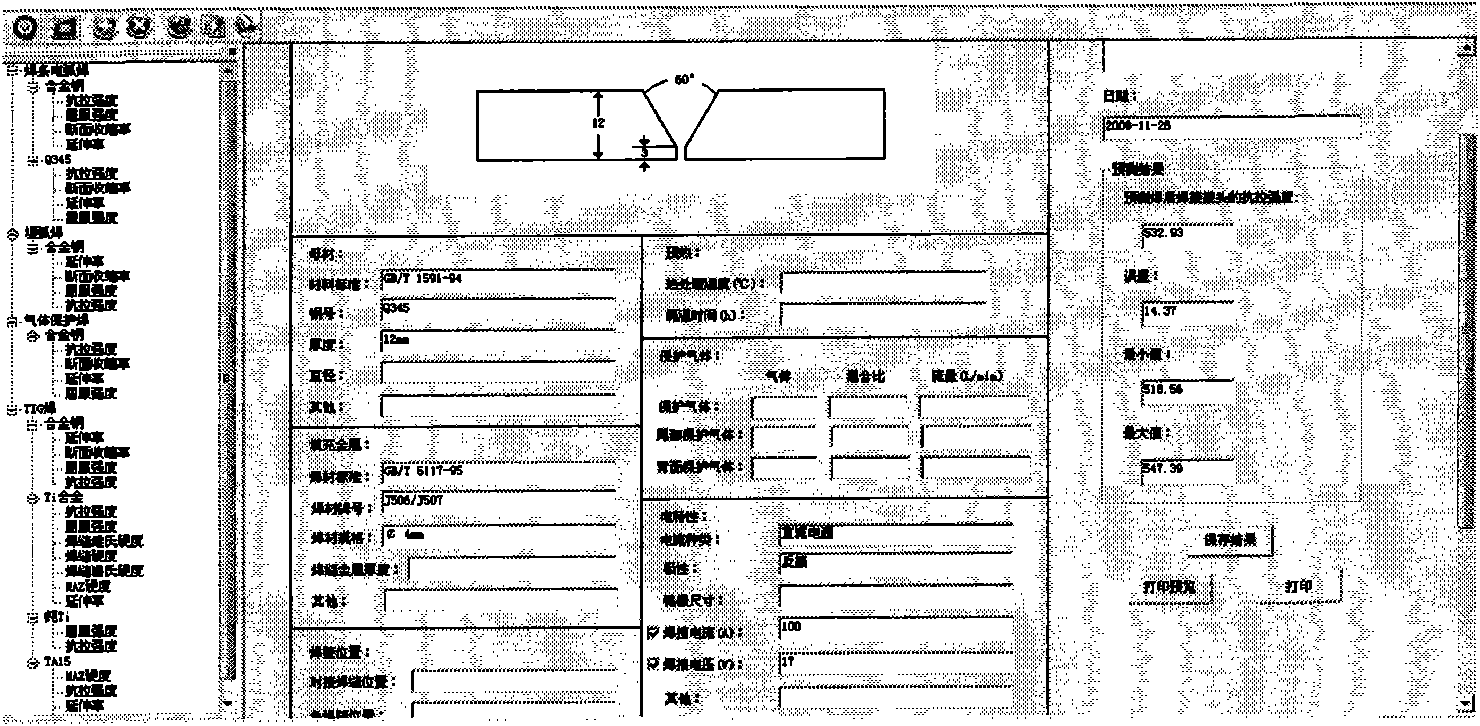

[0031] The present invention will be described in further detail below through specific embodiments and in conjunction with the accompanying drawings.

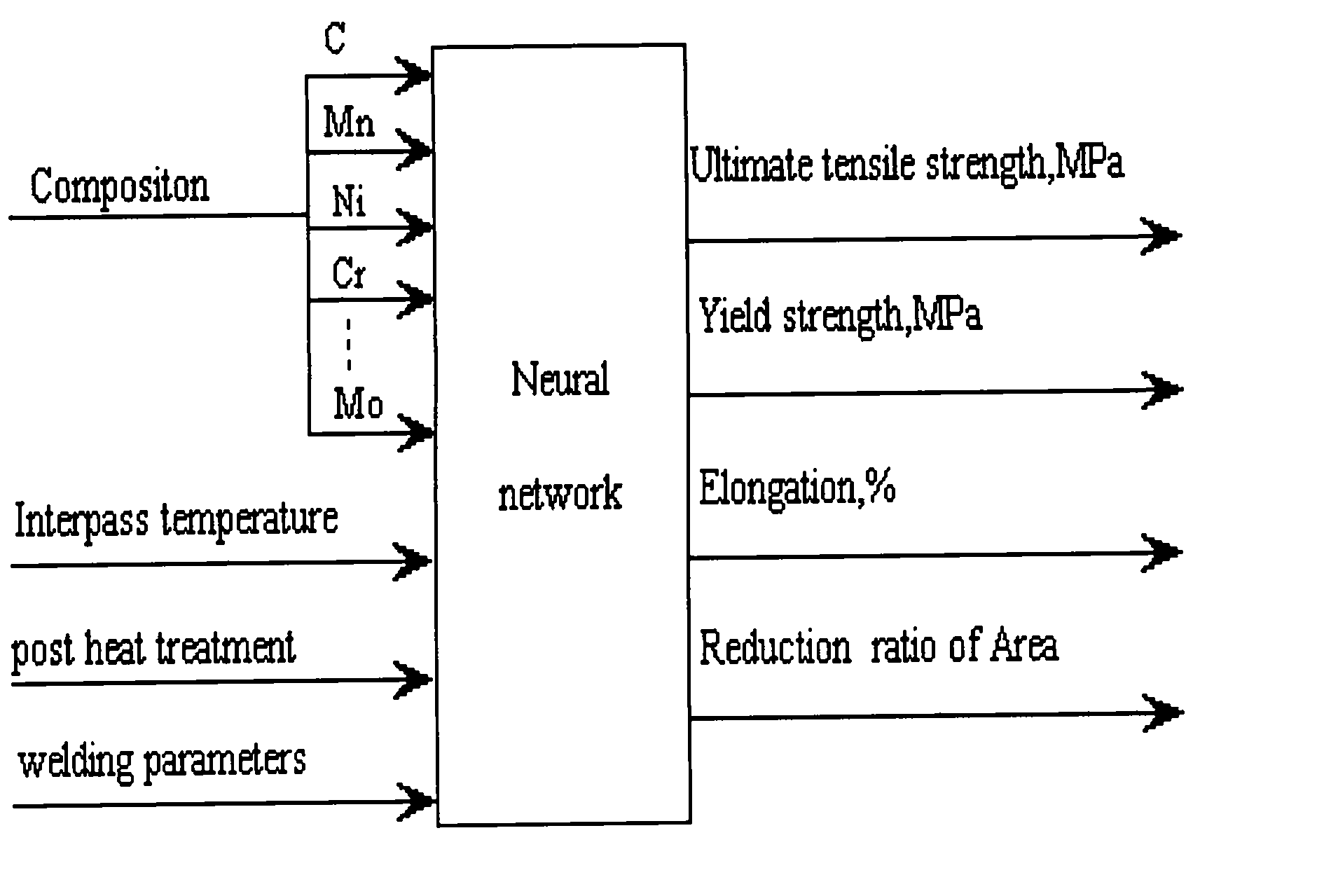

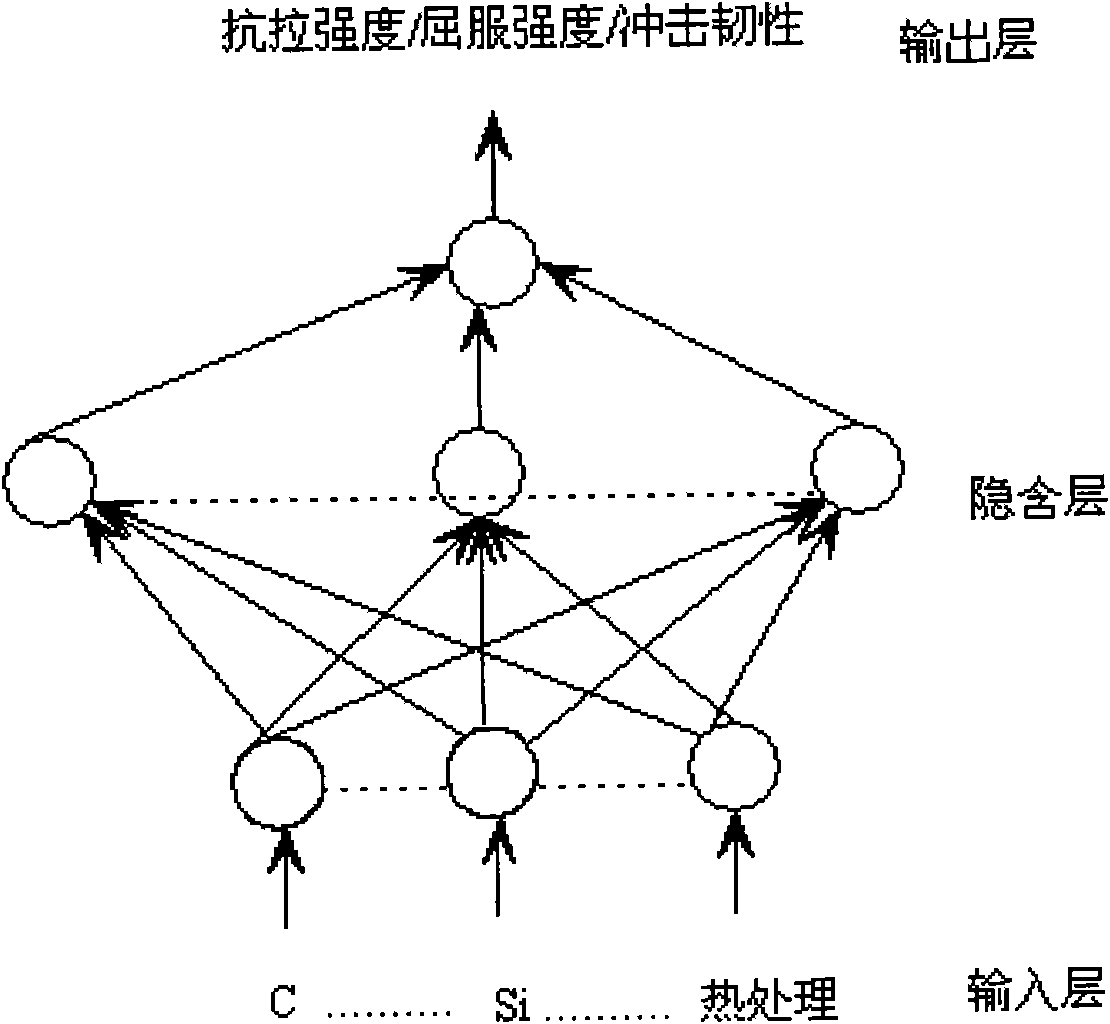

[0032] The interface system for predicting the mechanical properties of welded joints based on computer technology is as follows:

[0033] (1) Management and maintenance of the model

[0034] Due to the diversity of welding methods, the models produced are more diverse, and with the continuous generation of new models, in order to facilitate the management and update of models, this system realizes the function of adding and deleting models;

[0035] (1.1) Add model

[0036] The model generated by the neural network is stored in a folder, which contains some files used to define the input parameters and input parameter range of the model, as well as the weights, deviations, number of hidden units, and submodels of the neural network model Numbers, etc.; when using the neural network model to make predictions, the data must b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com