Copper alloy based sepiolite, ferric oxide, vermiculite and barium ferric oxide composite material and preparation method thereof

A technology of barium iron oxide and composite materials, which is applied in the field of metal materials and can solve problems such as poor microwave absorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

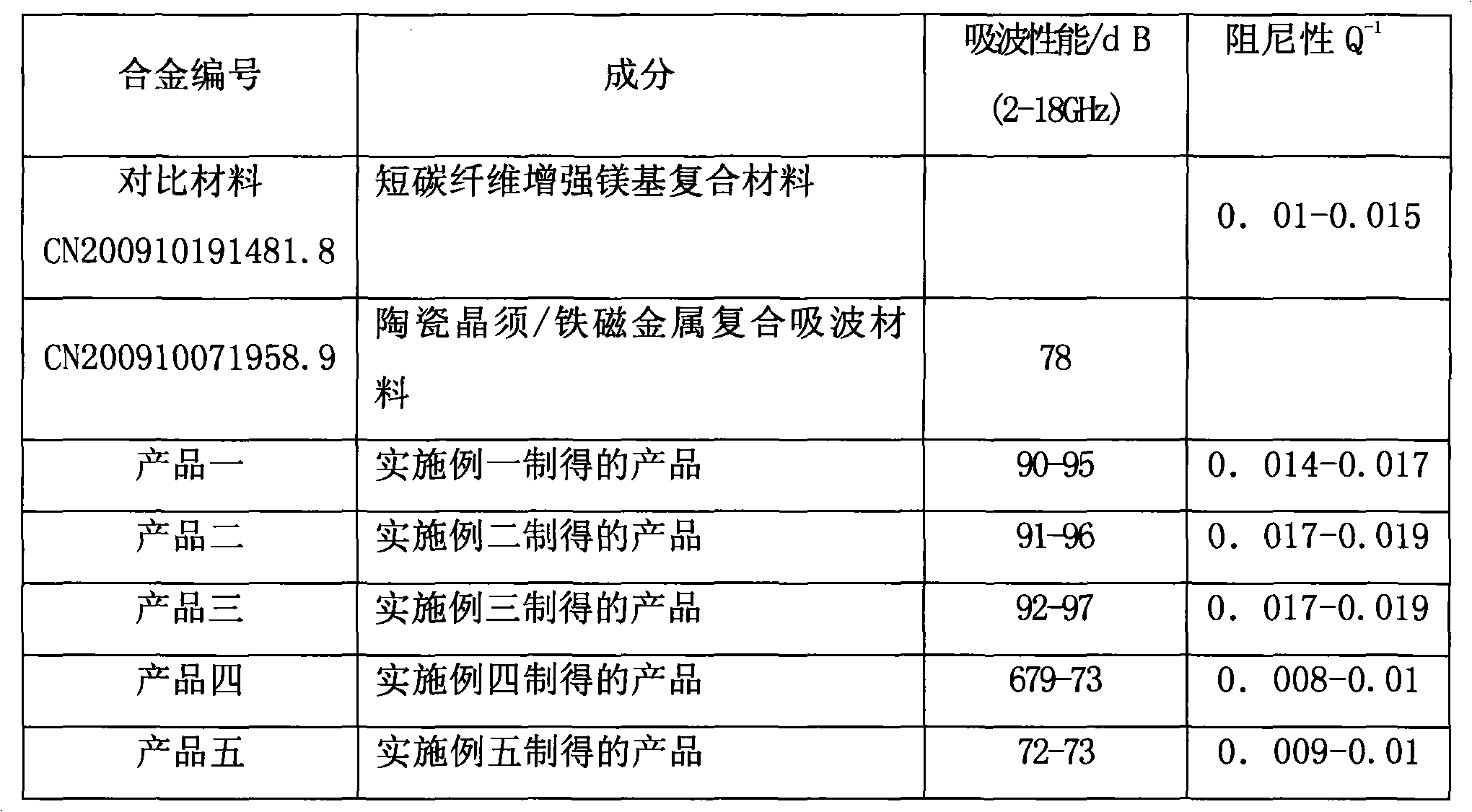

Examples

Embodiment 1

[0027] The preparation process of the copper alloy-based sepiolite iron oxide vermiculite iron barium oxide composite material of the present invention is as follows:

[0028] a. Preparation of vermiculite iron oxide barium compound:

[0029] Form a solution of ferric chloride, barium nitrate and citric acid in a ratio of 1:5:5, then put them into sepiolite vermiculite, and stir for 10 minutes in an 80 water bath. The size of vermiculite particles is 0.1mm. The solution and vermiculite The weight ratio is 5:1. After the stirring, the mixture is placed in an oven at 120°C for 30 minutes and then naturally cooled, and then placed in an oven at 550-590°C for 30 minutes and then naturally cooled to obtain vermiculite iron oxide Barium complex

[0030] b. Preparation of sepiolite iron oxide compound:

[0031] Then put ferric chloride and ferrous ammonium sulfate into a hydrothermal container lined with polytetrafluoroethylene, add water to dissolve (add a small amount of water to dissolve...

Embodiment 2

[0036] a. Preparation of vermiculite iron oxide barium compound:

[0037] The weight ratio of ferric chloride, barium nitrate and citric acid in the solution is 1:10:20, the size of vermiculite particles is 0.5 mm, and the weight ratio of solution to vermiculite is 10:1;

[0038] b. Preparation of sepiolite iron oxide compound: the weight ratio of ferric chloride, ferrous ammonium sulfate and sepiolite in the solution used in the preparation of sepiolite iron oxide compound is 1:1:2. The size is 1mm;

[0039] c. Preparation of composite preform: The weight ratio of vermiculite iron oxide barium to sepiolite iron oxide compound is 1:2; the volume percentage of sepiolite iron oxide vermiculite iron oxide barium to the composite material is 40 -50%;

[0040] d. Preparation of the copper alloy matrix: The weight percentage of the copper alloy matrix composition is 5% of Al, 0.1% of Te, 0.1% of Co, 0.01% of Pr, and the rest of Cu.

[0041] The preparation method is the same as in Example 1...

Embodiment 3

[0043] a. Preparation of vermiculite iron oxide barium compound:

[0044] The weight ratio of ferric chloride, barium nitrate and citric acid in the solution used is 1:7:10, the size of vermiculite particles is 0.3mm, and the weight ratio of solution to vermiculite is 7:1;

[0045] b. Preparation of sepiolite iron oxide compound: the weight ratio of ferric chloride, ferrous ammonium sulfate and sepiolite in the solution is 1:1:1.5, and the size of sepiolite particles is 0.6-1mm;

[0046] c. Preparation of composite preforms: the weight ratio of vermiculite iron oxide barium to sepiolite iron oxide compound is 1:1.5; the volume percentage of sepiolite iron oxide vermiculite iron oxide barium to the composite material is 40 -50%;

[0047] d. Preparation of the copper alloy matrix: the weight percentage of the copper alloy matrix composition is 4% Al, 0.07% Te, 0.07% Co, 0.008% Pr, and the rest is Cu.

[0048] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com