Anti-saline alkali corrosion resistance-reduction combined grounding body

A grounding body and combined technology, which is applied in the field of grounding grid, can solve the problems of low corrosion rate, affecting grounding performance, deformation resistance, poor compression mechanical performance, etc., and achieves improved flow and discharge capacity and corrosion resistance. , The effect of anti-corrosion grounding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

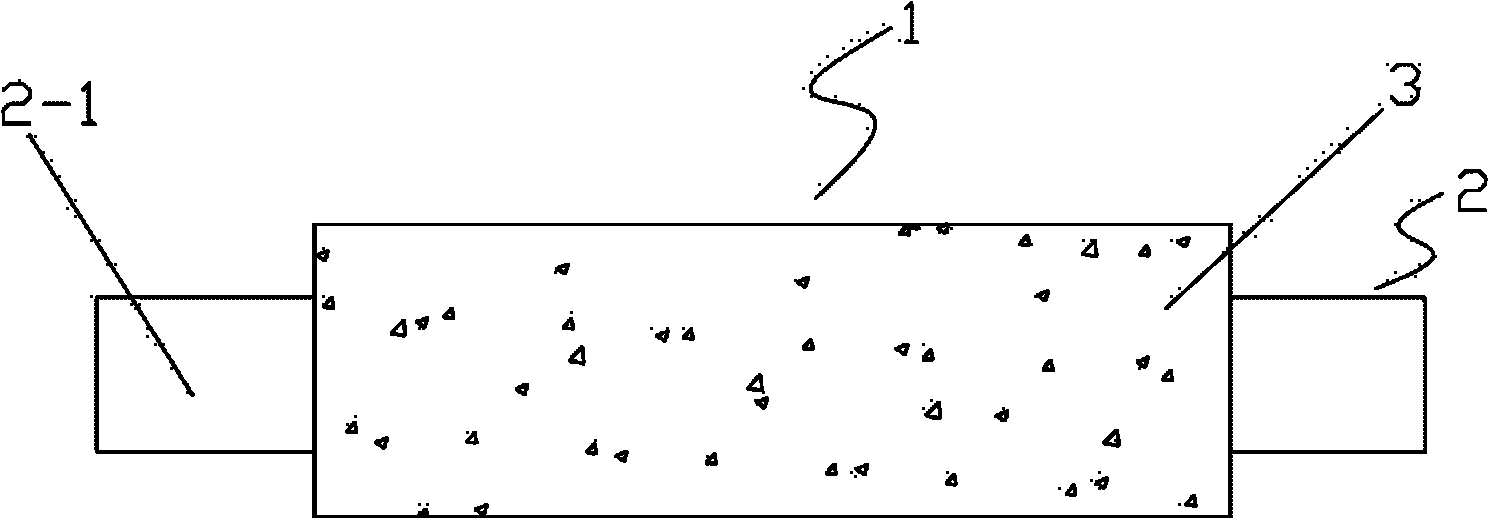

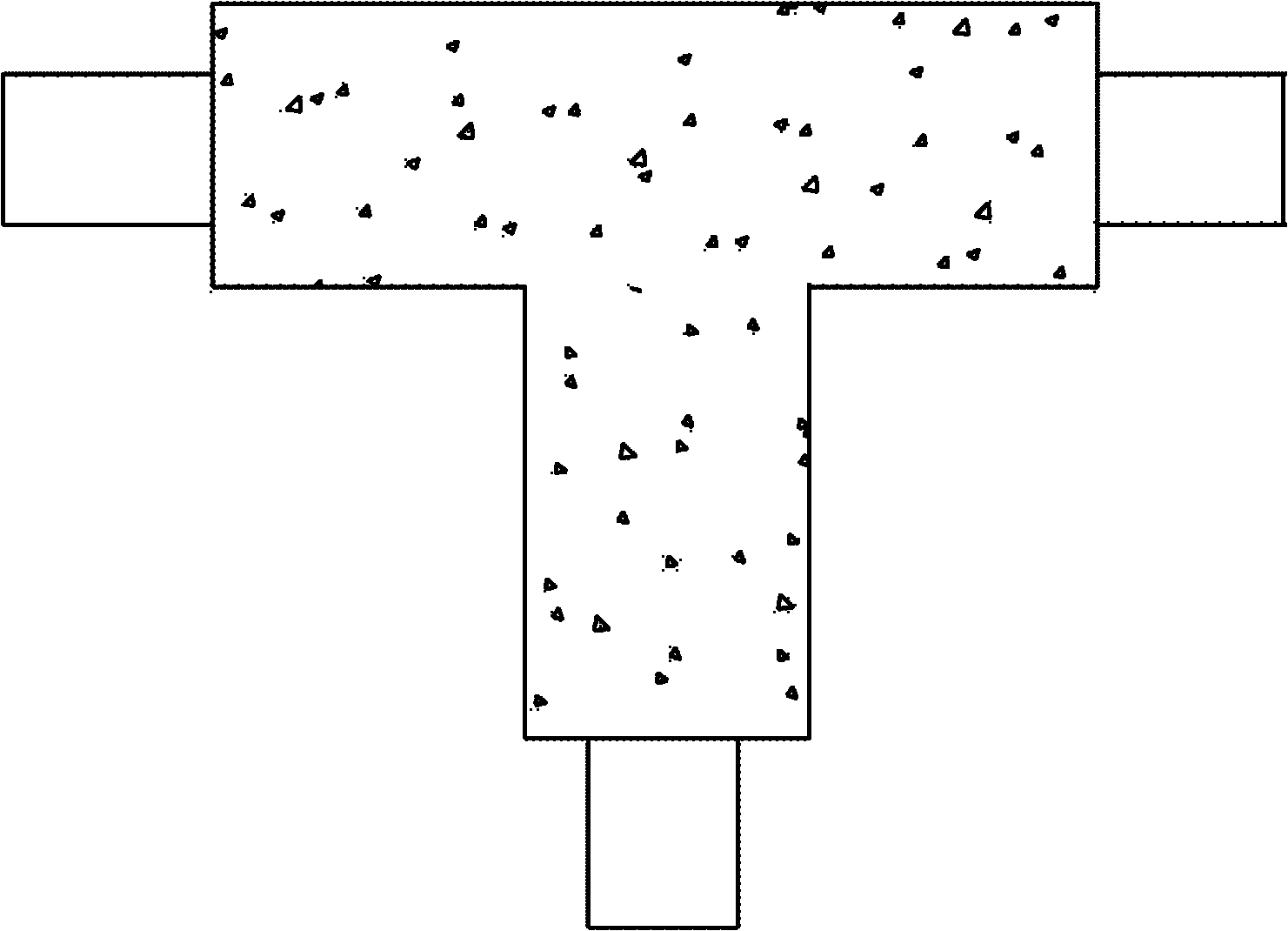

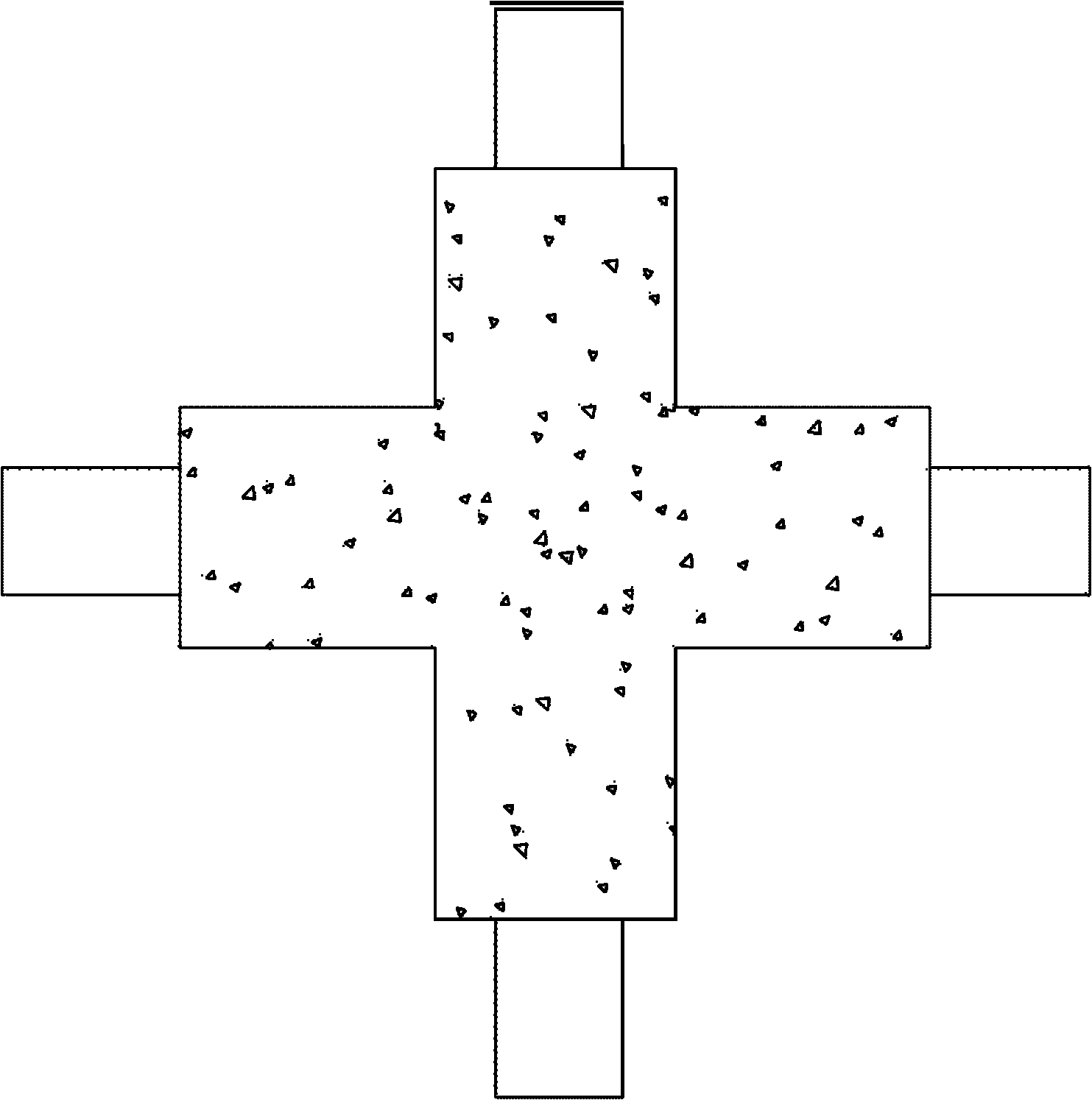

[0023] The specific implementation manner of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments. As shown in the figure, a combined grounding body that resists saline-alkali corrosion and reduces resistance. The grounding body 1 is mainly composed of an inner core 2 of galvanized flat steel and a conductive concrete outer cladding 3, and the conductive concrete outer cladding covers the inner core. Around, the fixed connection terminal 2-1 of the inner core extends to expose the outer end surface of the outer cladding. The shape of the grounding body is a strip shape or a T shape or a cross shape or a connection angle of 120°. The cross-sectional area of the inner core of the galvanized flat steel is 5x50 square millimeters. The thickness of the conductive concrete outer cladding is greater than or equal to 10 mm.

[0024] The resistivity of the saline-alkali-resistant grounding body in a dry stat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com