Organic single flow battery

A flow battery, single-liquid technology, applied in the direction of fuel cells, battery electrodes, battery components, etc., can solve the problems of cycle life, less maintenance, complex structure, etc., and achieve less maintenance, high energy efficiency, energy density and power density high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

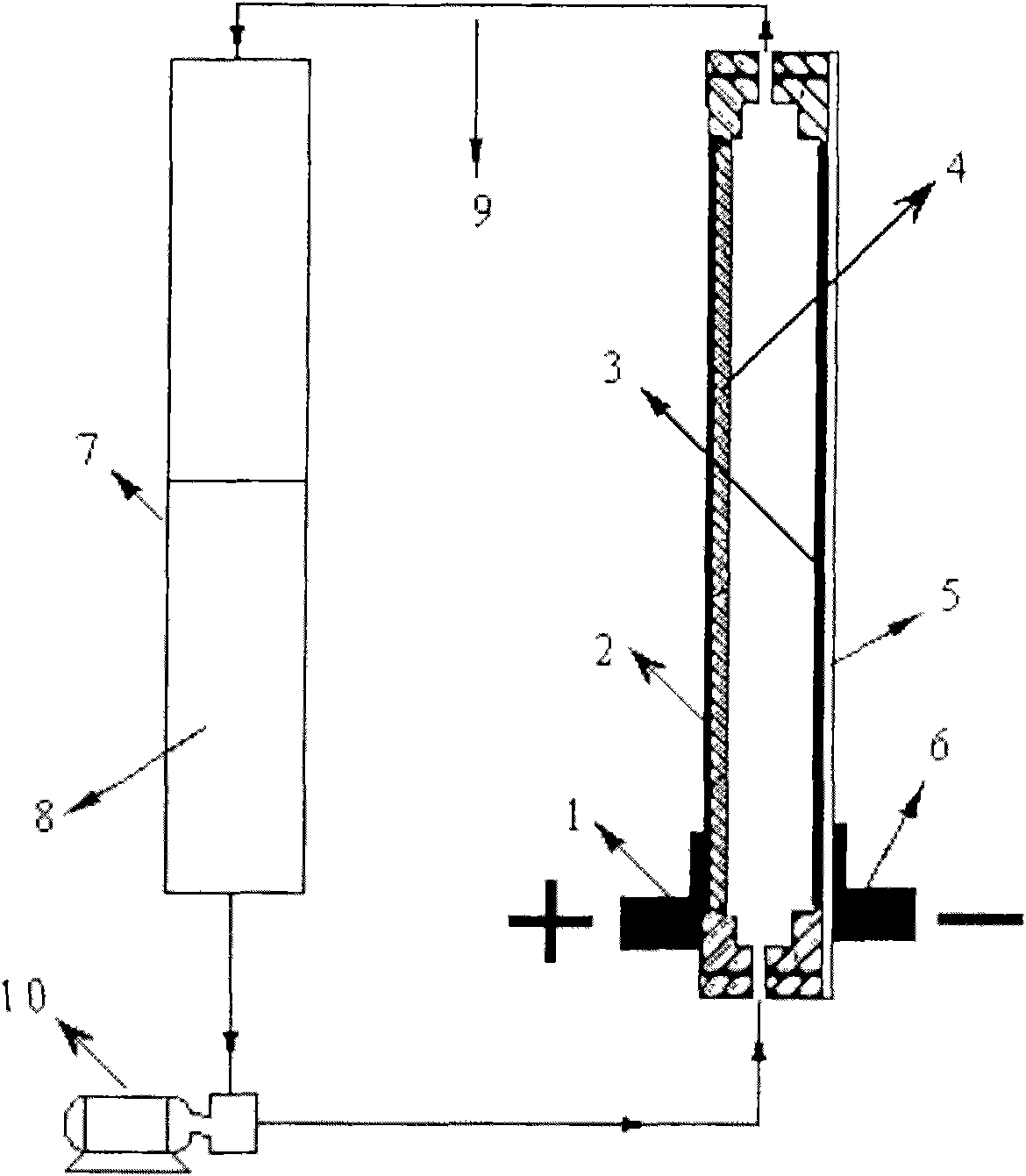

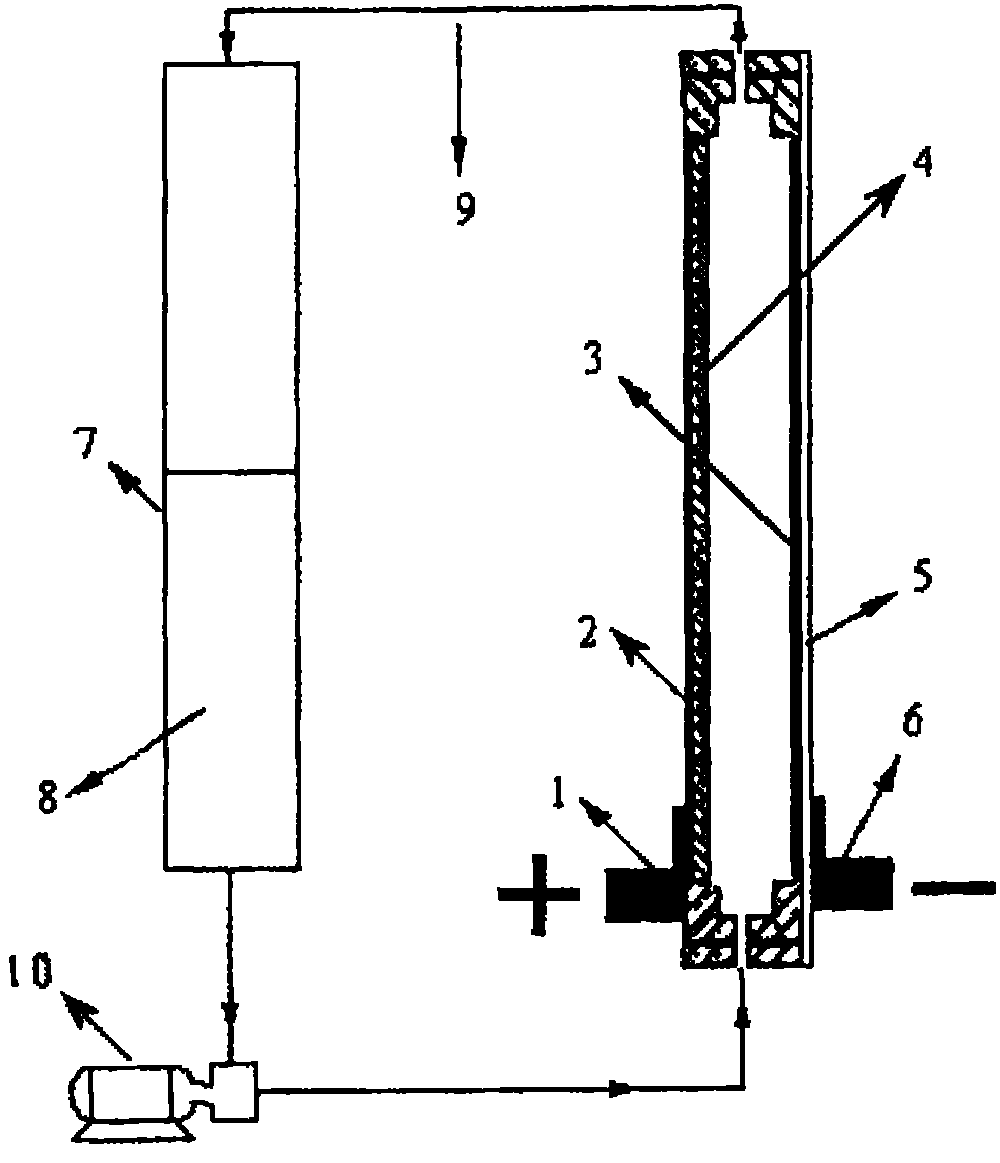

Method used

Image

Examples

Embodiment 1

[0031] Mix the ball-milled chloranil with 40% graphite powder and 10% PTFE binder and press it into a sheet, press it on the graphite current collector with a conductive adhesive, and get a surface capacity of 2mAh after pre-discharge cm -2 organic solid electrodes. at 1.5cm 2 The titanium-based lead-plated electrode is the negative current collector, and 50mL of 1M H 2 SO 4 +1M Na 2 SO 4 +0.5M CdSO 4 The solution is an electrolyte. The MP-10RN magnetic circulation pump is used as the power pump to circulate the electrolyte over the positive / negative electrode surface of the battery. The open circuit voltage of the battery is about 1.20V, at 5mA·cm -2 The average discharge voltage is about 1.10V, the energy efficiency of this process is about 88%, the charge and discharge cycle is 50 times, and the battery performance decay rate is less than 5%.

Embodiment 2

[0033] Mix the ball-milled chloranil with 50% graphite powder and 5% PTFE binder and press it into a sheet, press it on the graphite current collector with a conductive adhesive, and obtain a surface capacity of 2mAh after pre-discharge cm -2 organic solid electrodes. at 1.5cm 2 The titanium-based galvanized electrode is the negative current collector, and 50mL of 3M NH 4 Cl+1.0M ZnCl 2 The solution is an electrolyte. The MP-10RN magnetic circulation pump is used to circulate the electrolyte over the positive / negative electrode surface of the battery. The open circuit voltage of the battery is about 1.10V, at 10mA·cm -2 The average discharge voltage is about 1.0V, the energy efficiency of this process is about 81%, the charge and discharge cycle is 50 times, and the battery performance decay rate is less than 10%.

Embodiment 3

[0035] The double-sided lamination rated surface capacity is 2mAh cm -2 The graphite plate of tetrachlorophenol is the positive electrode, with 1*1.5cm 2 The lead-plated nickel mesh electrode is the negative current collector, 100mL of 0.5MH 2 SO 4 +1MK 2 SO 4 +0.5M CdSO 4 The aqueous solution is an electrolyte, and 0.5 g / L of gelatin is added to the electrolyte. The MP-10RN magnetic circulation pump is used as the infusion pump to circulate the electrolyte over the positive / negative electrode surface of the battery. The open circuit voltage of the battery is 1.20V, 10mA cm -2 The average discharge voltage is about 1.10V, the energy efficiency of this process is about 85%, the charge and discharge cycle is 50 times, and the battery performance decay rate is less than 10%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com