Conductive polyester/graphite oxide composite material and preparation method thereof

A technology for composite materials and conductive properties, applied in the field of polyester composite materials with conductive properties and its preparation, can solve the problems of reduced specific surface area, adhesion, and easy collapse of expanded graphite, etc., to achieve high conductivity and low filler content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

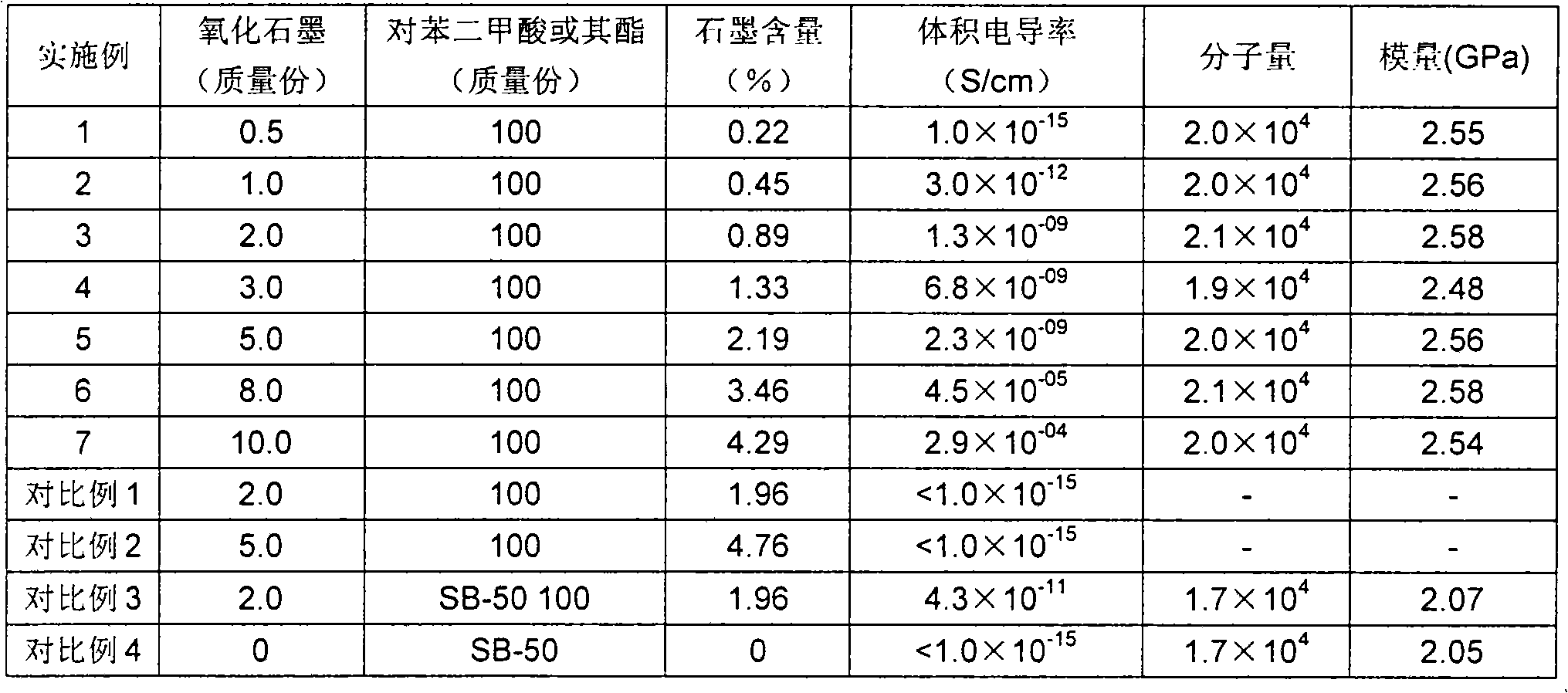

Examples

preparation example Construction

[0061] The preparation method of graphite oxide is:

[0062] Take 400 parts by mass of 98% concentrated sulfuric acid and place it in an ice bath, add 10 parts by mass of natural flake graphite or expanded graphite, 5 parts by mass of sodium nitrate, and 30 parts by mass of potassium permanganate, stir mechanically for 1 hour, and keep the temperature of the mixture below 20°C. The ice bath was removed, the mixed solution was placed in a water bath at 35° C. for 4 hours, and then diluted with 500 parts by mass of deionized water, and the mixed solution was maintained at 90° C. for 15 minutes. Dilute with 900 parts by mass of deionized water, add 60 parts by mass of hydrogen peroxide and filter while hot. Wash with deionized water until SO-free 4 2- ion.

[0063] Among them, the particle size of natural flake graphite or expanded graphite used as raw material is between 10 3 ~10 6 head. The thickness of the graphite oxide flakes obtained after oxidation and peeling is 1-...

Embodiment 1

[0065] 0.5 parts by mass of graphite oxide and 63.5 parts by mass of ethylene glycol were mixed and ultrasonically oscillated for 2.0 hours to obtain a premix. The premix was mixed with 100 parts by mass of terephthalic acid, 0.3 parts by mass of zinc acetate, and 0.024 parts by mass of cobalt acetate at 120° C., and reacted at 230° C. for 2 hours at normal pressure and 1 hour at 250° C. to obtain a prepolymer. Mix the prepolymer with 0.36 parts by mass of antimony trioxide and 0.048 parts by mass of triphenyl phosphate, the precondensation pressure is 23kPa, the temperature is 250°C, and the reaction is 1.2 hours; the precondensation pressure is 300kPa, the temperature is 270°C, and the reaction is 1.0 hours; the final polycondensation pressure was 200 Pa, the temperature was 275°C, and the reaction was carried out for 1.5 hours. The resulting product was discharged under nitrogen pressure, crushed and then transferred to a rotary evaporator. Under nitrogen protection, it was...

Embodiment 2

[0067] 1.0 parts by mass of graphite oxide, 60 parts by mass of ethylene glycol, and 6.7 parts by mass of deionized water were mixed, ultrasonically oscillated and mechanically stirred for 3.0 hours to obtain a premix. Mix the premix with 100 parts by mass of dimethyl terephthalate and 0.2 parts by mass of manganese acetate at 160°C, react at normal pressure at 160°C for 2 hours, at 190°C for 2 hours, and at 230°C for 2 hours to obtain a prepolymer . Mix the prepolymer with 0.5 parts by mass of antimony trioxide and 0.1 parts by mass of triphenyl phosphate, the precondensation pressure is 20kPa, the temperature is 250°C, and the reaction is 1.2 hours; the precondensation pressure is 280kPa, the temperature is 275°C, and the reaction is 1.0 hour; the final polycondensation pressure is 100Pa, the temperature is 280°C, and the reaction is 1.0 hour. The resulting product was discharged under nitrogen pressure, crushed and then transferred to a rotary evaporator. Under a pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com