Full-solid potassium ion sensor and preparation method thereof

A potassium ion, all-solid-state technology, used in instruments, scientific instruments, measuring devices, etc., can solve the problems of not easy to carry, time-consuming detection, etc., and achieve the effects of stable work, simplified production process, and rapid response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

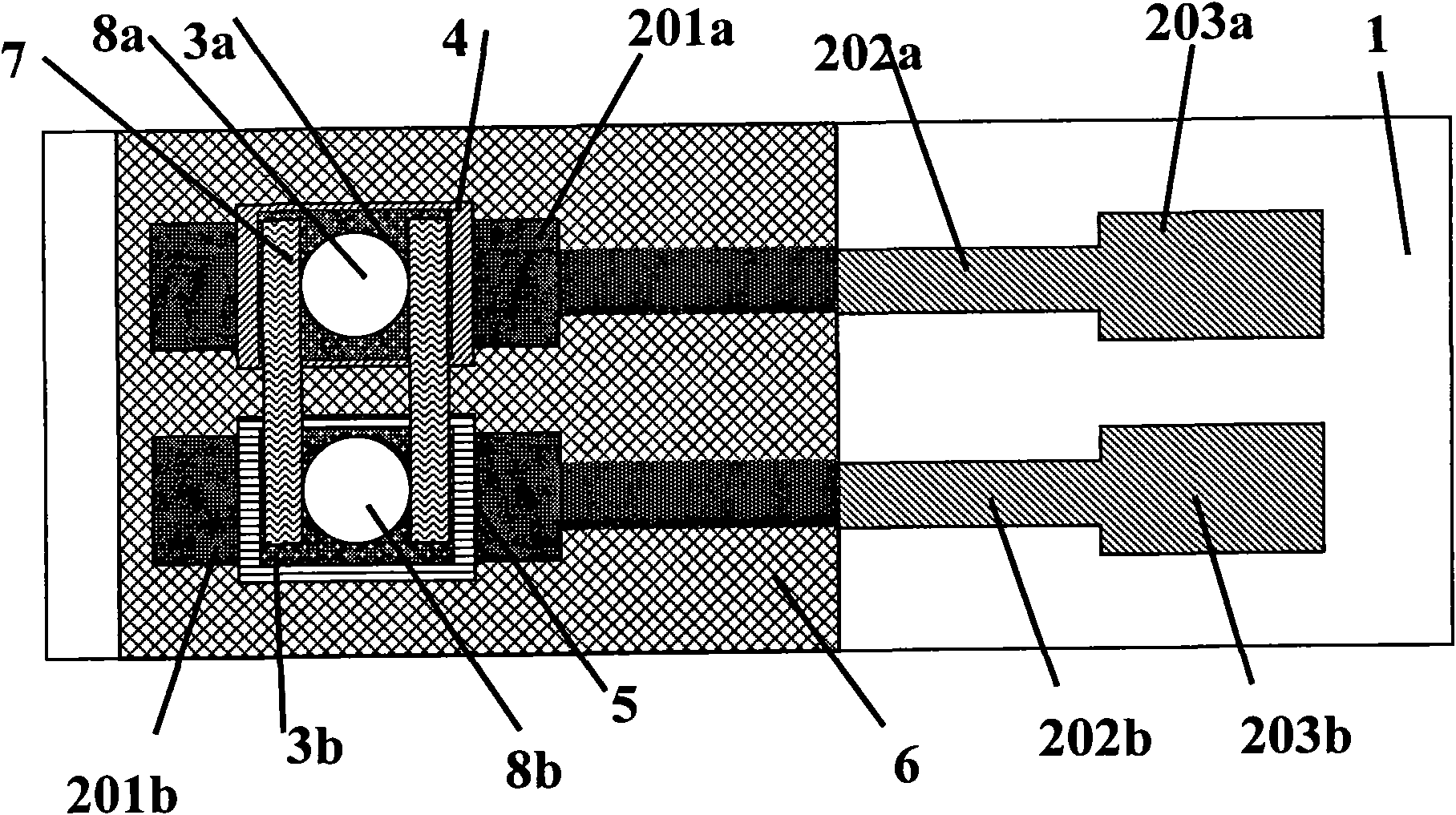

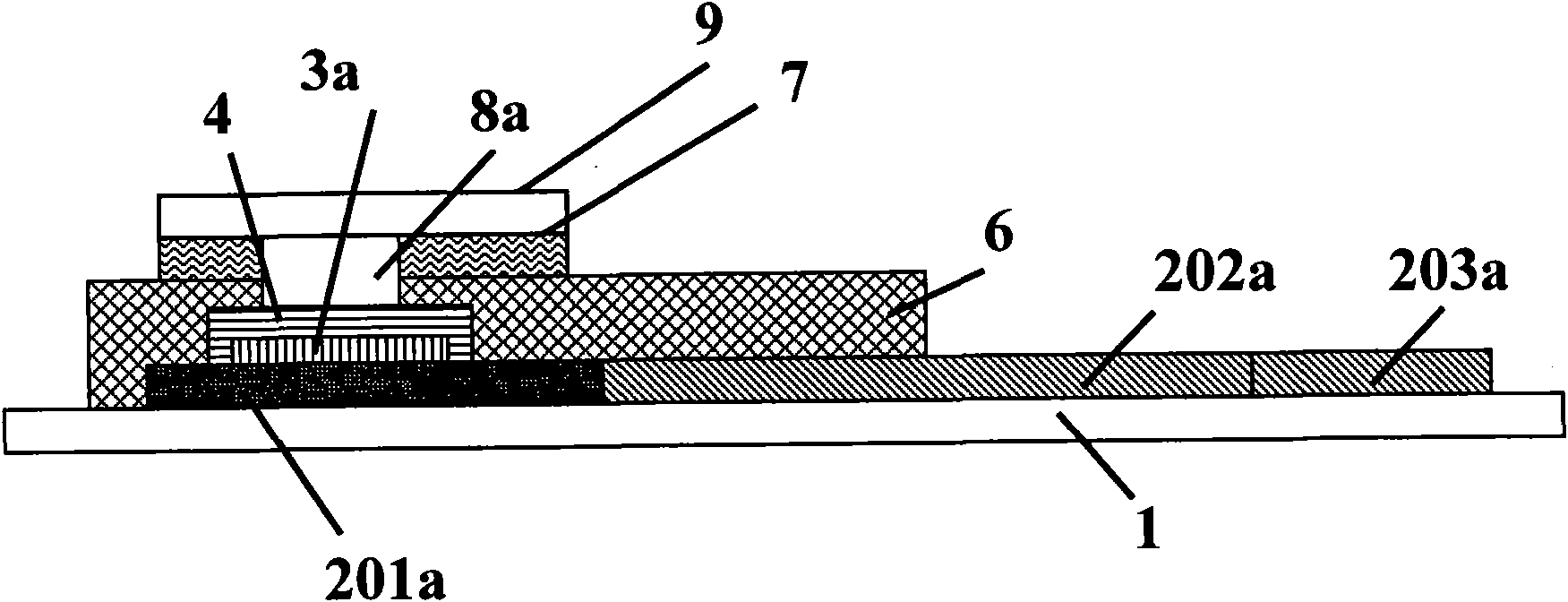

[0048] The preparation of a kind of all-solid-state potassium ion sensor comprises the following steps:

[0049] (1) The carbon printing material is printed on the polypropylene substrate by screen printing technology to form the reaction electrode of the potassium ion selective electrode and the external reference electrode, and the silver printing material is printed on the polypropylene substrate by the screen printing technology, forming conductive leads and contact electrodes connected to the reaction electrodes;

[0050] (2) use the CMC aqueous solution that mass percent is 3 ‰ to scrub the reaction electrode surface, then wipe clean;

[0051] (3) Poly 3,4-ethylenedioxythiophene / polystyrene sulfonic acid (PEDOT / PSS, Clevios P of German H.C.Starck Company, CAS No.155090-83-8) is dispersed in water to form a suspension, which The ratio is PEDOT / PSS:H 2 O=1:99, PEDOT / PSS vs. CO 2 (pH), O 2 It is insensitive and can improve the stability of measurement. Based on the to...

Embodiment 2

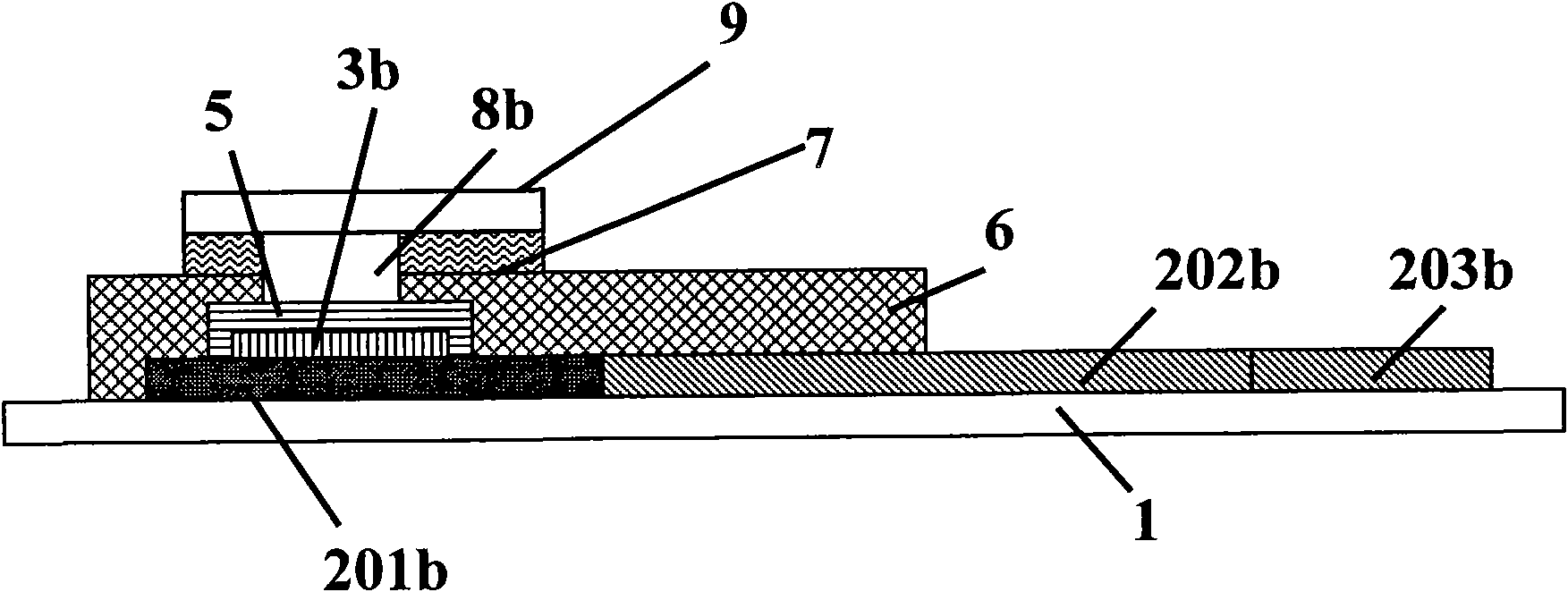

[0063] The preparation of a kind of all-solid-state potassium ion sensor comprises the following steps:

[0064] (1) The carbon printing material is printed on the polypropylene substrate by screen printing technology to form the reaction electrode, the conductive lead wire and the contact electrode of the potassium ion selective electrode and the external reference electrode;

[0065] (2) use the HEC aqueous solution that the mass percentage is 2 ‰ to scrub the reaction electrode, and then wipe it clean;

[0066] (3) Disperse PEDOT / PSS in water to form a suspension at a ratio of PEDOT / PSS:H 2 O=1:99, based on the total amount of the suspension, add TritonX-100 with a mass percentage of 0.5‰ and HEC with a mass percentage of 2% to the suspension to form an electrolyte slurry, and use the method of screen printing. The slurry is printed on the surface of the reaction electrode to form an electrolyte layer with a thickness of about 20 μm. The screen used is 150 mesh, the screen...

Embodiment 3

[0073] The preparation of a kind of all-solid-state potassium ion sensor comprises the following steps:

[0074] (1) The carbon printing material is printed on the polypropylene substrate by screen printing technology to form the reaction electrode, the conductive lead wire and the contact electrode of the potassium ion selective electrode and the external reference electrode;

[0075] (2) use the CMC aqueous solution that mass percent is 3 ‰ to scrub the reaction electrode surface, then wipe clean;

[0076] (3) Disperse PEDOT / PSS in water to form a suspension at a ratio of PEDOT / PSS:H 2 O=1:99, based on the total amount of the suspension, add 3% CMC to the suspension to form an electrolyte slurry, which is printed on the surface of the reaction electrode by screen printing to form an electrolyte layer. The thickness is about 20μm, the stencil used is 150 mesh, the mesh distance is 1mm, the scraper speed is 8mm / s, and the pressure is 1.8kg / cm 2 ;

[0077] (4) Add 1.27 mg of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com