Method for preparing liquid alkane fuel by upgrading bio-oil in aqueous phase catalytic mode

A liquid alkane and bio-oil technology, which is applied in the fields of chemical technology and biomass utilization, can solve the problems of unsatisfactory catalytic cracking effect, carbon coking on the catalyst surface, unstable bio-oil properties, etc. The effect of high quality and wide raw material adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

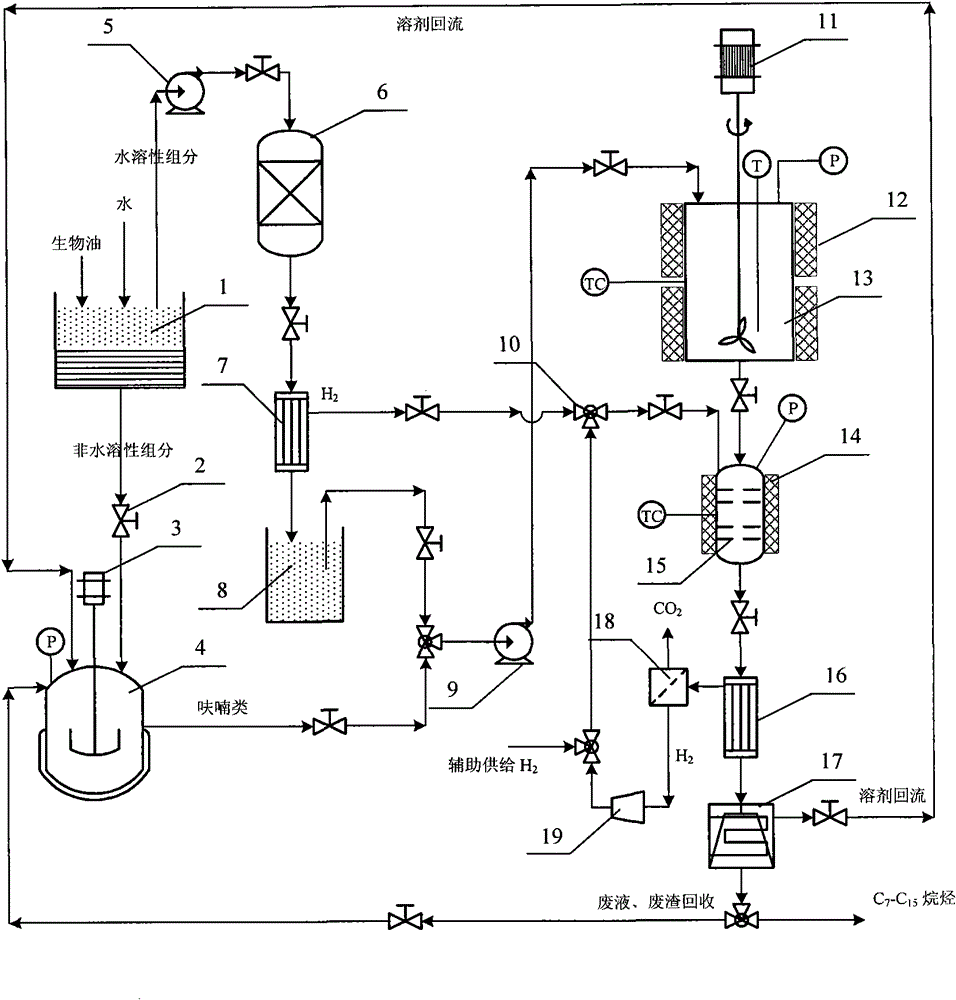

[0039] Embodiment 1, the method and effect of upgrading the quality of fast pyrolysis oil a

[0040] 1) Please refer to Figure 1, take 200g of biomass rapid pyrolysis oil a (see Table 1 for physical properties) and put it into bio-oil storage tank 1, press H at normal temperature and pressure 2 Distilled water was added at a mass ratio of O: bio-oil of 10:1, stirred for 12 hours, cooled and left at -2°C for 12 hours, precipitated and filtered to obtain water-soluble components and water-insoluble components.

[0041] 2) After taking out the water-insoluble component, put it into the acid hydrolysis reactor 4, close the back pressure valve 2, and add THF and distilled water according to the mass ratio of the water-insoluble component, tetrahydrofuran THF, and water 2:2:1, and add HCl adjusts the pH value of the solution below 2, covers the reactor 4 upper cover and uses N 2 After replacing the air, pressurize the reactor 4 to 0.8MPa, turn on the agitator a3, raise the temperat...

Embodiment 2

[0047] Embodiment 2, the upgrading method and effect of rapid pyrolysis oil b

[0048] The rapid pyrolysis oil b was upgraded using the same experimental device and process as in Example 1. The physical properties of the pyrolysis oil b are shown in Table 1.

[0049] Step 1), 2), 3), 4) are the same as Example 1, change step 5) reaction conditions, in the first step hydrogenation, H 2 The pressure was adjusted to 2MPa, and the rest remained unchanged, and the step 6) of the same reaction conditions as in Example 1 was carried out to obtain the physical property results of the liquid phase product as shown in Table 2. After analysis, the oxygen content of the product oil was reduced to 3.2%, the H / C ratio was 1.42, the pH value was 5.0, and the C in the oil 7 -C 15 The mass fraction of linear alkanes is 74%. Compared with the quality of the oil product obtained in Example 1, the quality of the oil product is slightly reduced, which can be attributed to the following two rea...

Embodiment 3

[0050] Embodiment 3, the upgrading method and effect of slow pyrolysis oil c

[0051] The slow pyrolysis oil c was upgraded using the same experimental device and process as in Example 1. The physical properties of the pyrolysis oil c are shown in Table 1.

[0052] All steps and reaction conditions are the same as in Example 1, and the results of the physical properties of the liquid phase product are shown in Table 2. After analysis, the oxygen content of the product oil was reduced to 1.5%, the H / C ratio was 1.64, the pH value was 5.2, and the C in the oil 7 -C 15 The mass fraction of linear alkanes is 80%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com