Method for treating and recycling circulating wastewater

A sewage and circulating water technology, applied in the direction of flotation water/sewage treatment, neutralized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problem of high operating costs and achieve continuous treatment and water production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Embodiment 1 The specific embodiment of the processing system that the process of the present invention adopts

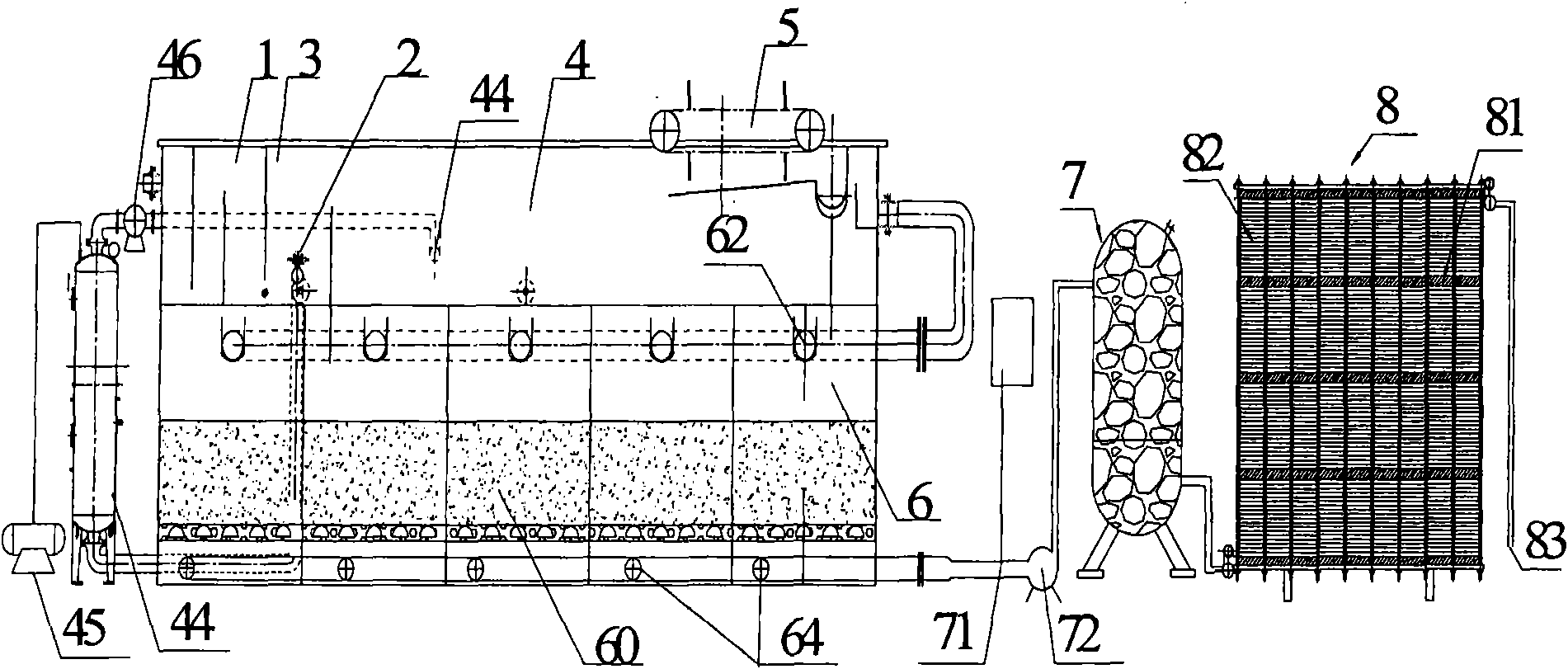

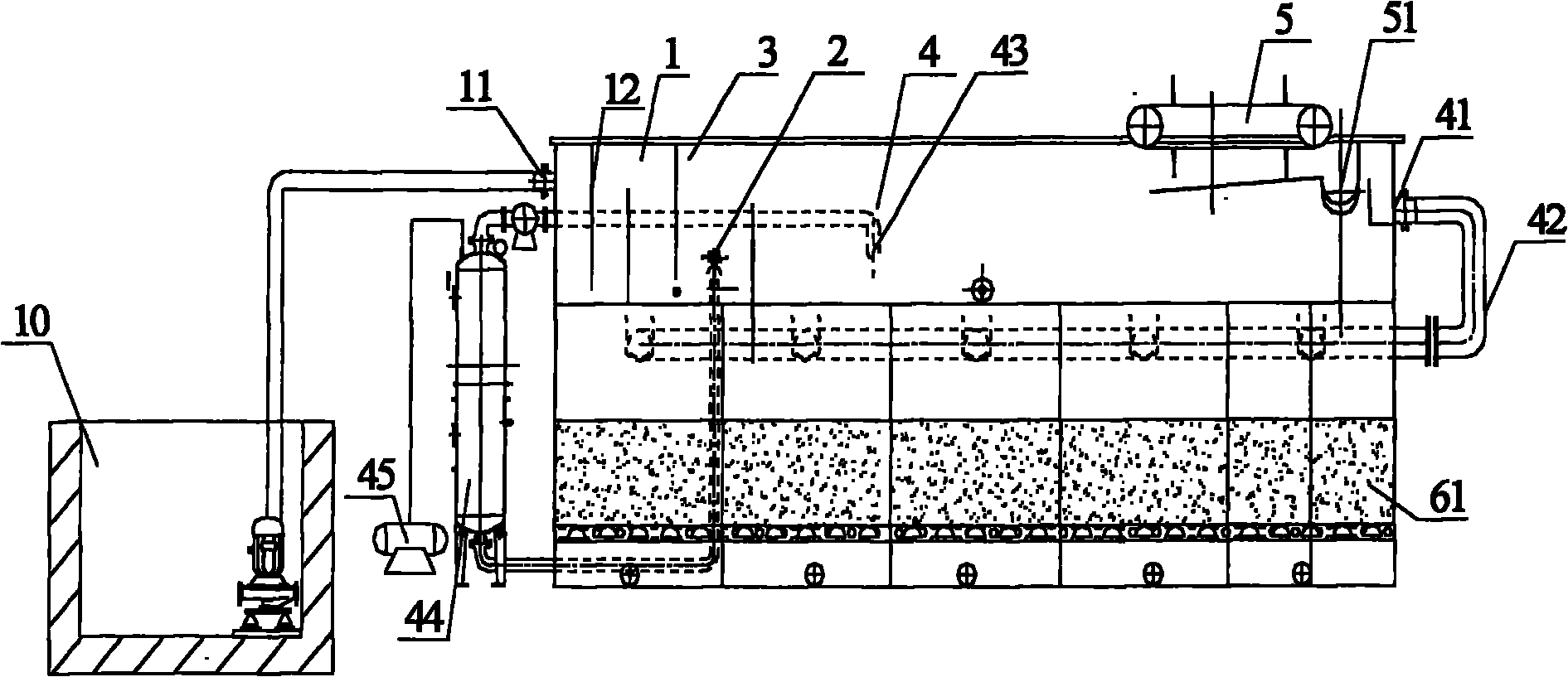

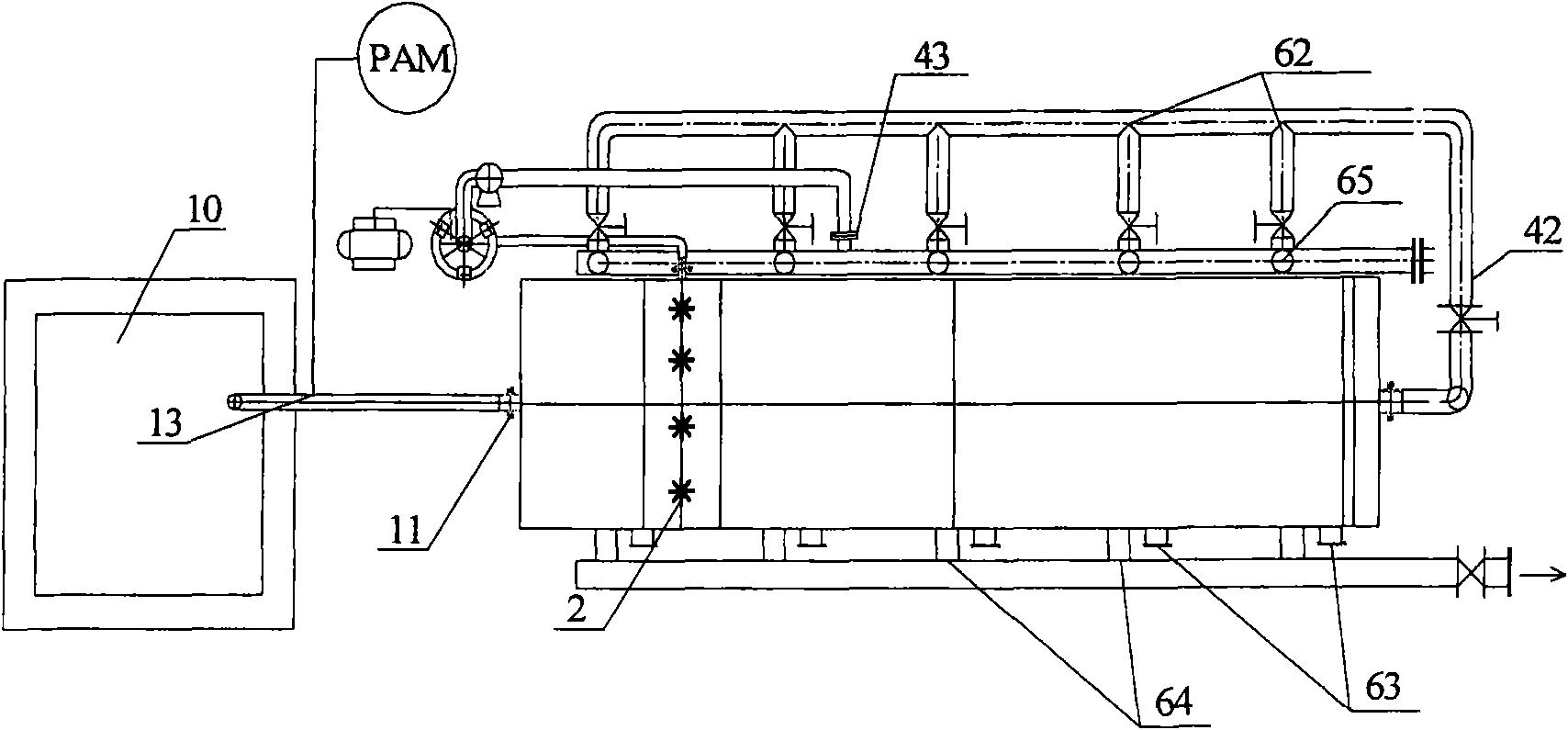

[0067] Please combine Figure 1-Figure 4 , this embodiment provides a recycling treatment system for circulating water and sewage, including a flocculation-air flotation-filtration integrated device, a security filter and a frequent electrode reversal electrodialysis device, wherein,

[0068] The flocculation-air flotation-filtration integrated device is equipped with a flocculation zone 1, an air flotation zone 4 and a filtration zone 6. The flocculation zone 1 is provided with a sewage inlet 11, and the flocculation zone 1 is connected to the air flotation zone 4; A plurality of baffles 12, the spacing of these baffles 12 increases gradually along the water flow direction, and the distance adjacent to the air flotation area 4 forms a contact chamber 3, in which the dissolved air of the dissolved air and water release mechanism is arranged. Water release de...

Embodiment 2

[0076] Example of Circulating Water Sewage Treatment and Reuse

[0077] Due to the serious differences in water quality in different regions and the concentration ratio of circulating water in different regions, there are also great differences in the quality of circulating water sewage and fresh replenishment water. The applicant in this case made statistics on the circulating water sewage and fresh water replenishment water quality of 15 circulating water fields in 9 regions across the country. The specific statistical results are shown in the table below:

[0078] Table 4: Statistical Table of Circulating Water Sewage and Replenishment Water Quality of 15 Circulating Water Fields in 9 Regions of the Country in 2007

[0079]

[0080] From the statistical results in Table 4, it can be seen that the salinity level of the circulating water of Lanzhou Petrochemical and 14 water fields in 9 regions of the country is lower than that of the circulating water of Fushun Air Separat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com