Soft belt type electromagnetic induction heater

An electromagnetic induction and heater technology, which is applied in the direction of induction heating, induction heating devices, metal processing equipment, etc., can solve the problems of large influence of external climate interference, influence on welding quality and work efficiency, and uneven heating temperature, so as to reduce labor intensity , easy operation, and improved preheating efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Embodiment. This example is a prototype of the soft belt electromagnetic induction heater tested, and the test was carried out on a pipeline with a diameter of 1219mm and a wall thickness of 18.4mm at a certain construction site.

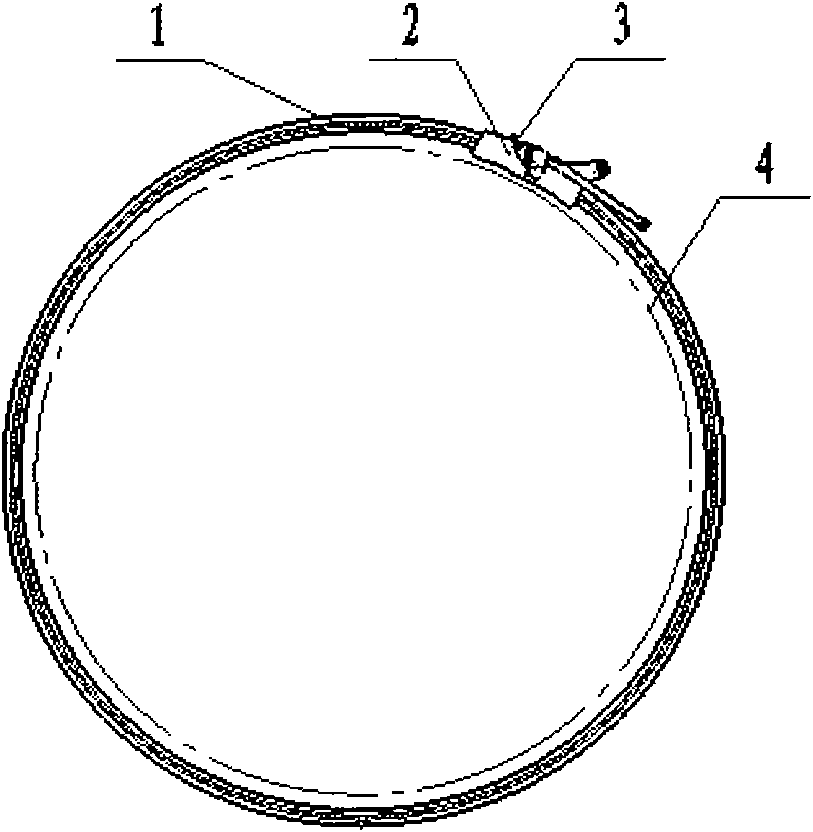

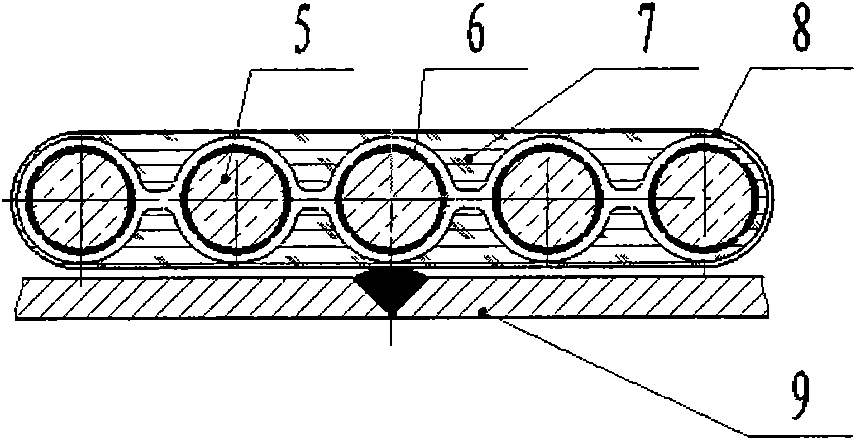

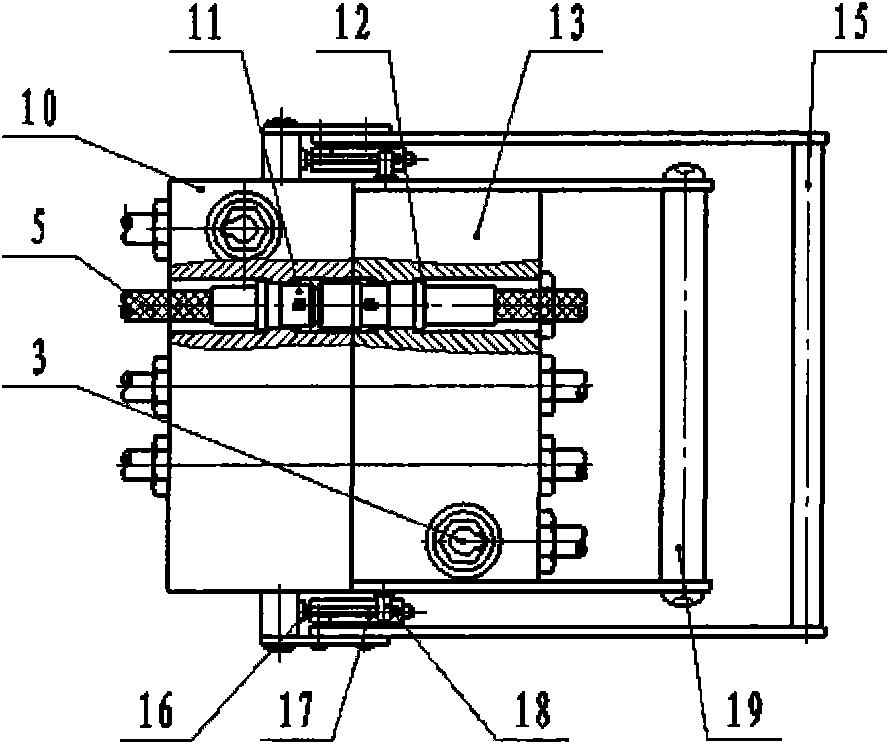

[0049] The structure of this example is as follows figure 1 As shown, it is composed of soft belt 1, electrical connector 2, electrical connector opening and closing mechanism 3, quick connector socket 4, high-frequency flexible cable 5, sheath 6, insulating fiber 7 and high temperature resistant flame retardant cloth 8, etc. .

[0050] The two ends of the soft belt 1 with four high-frequency flexible cables 5 inside are respectively connected to the electrical connector 2, and the multiple high-frequency flexible cables 5 are spirally connected to the heating coil body through the quick connector socket 4 in the electrical connector 2, and finally Two outward quick connector sockets 4 are formed to connect to the intermediate frequency powe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com