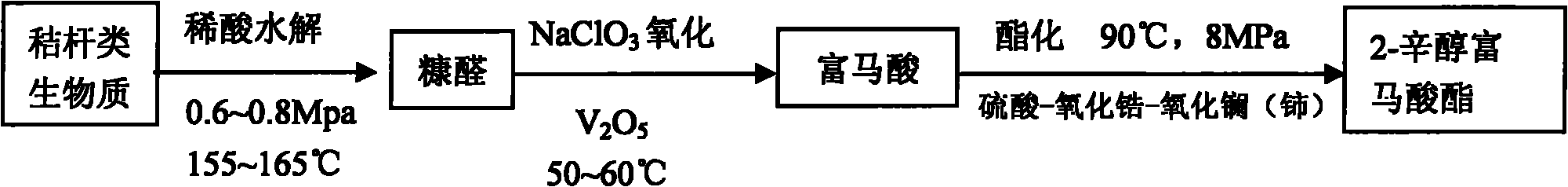

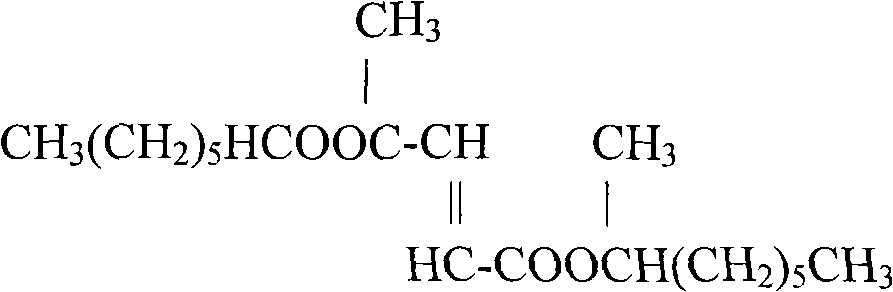

Method for preparing fumaric acid ester by using plant straws

A technology of plant straw and alcohol fumarate, which is applied in the field of fumarate preparation, can solve the problems such as no research report on polyester oil synthetic lubricant fumarate, and achieves easy control of process conditions and yield. The effect of high rate and high product purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

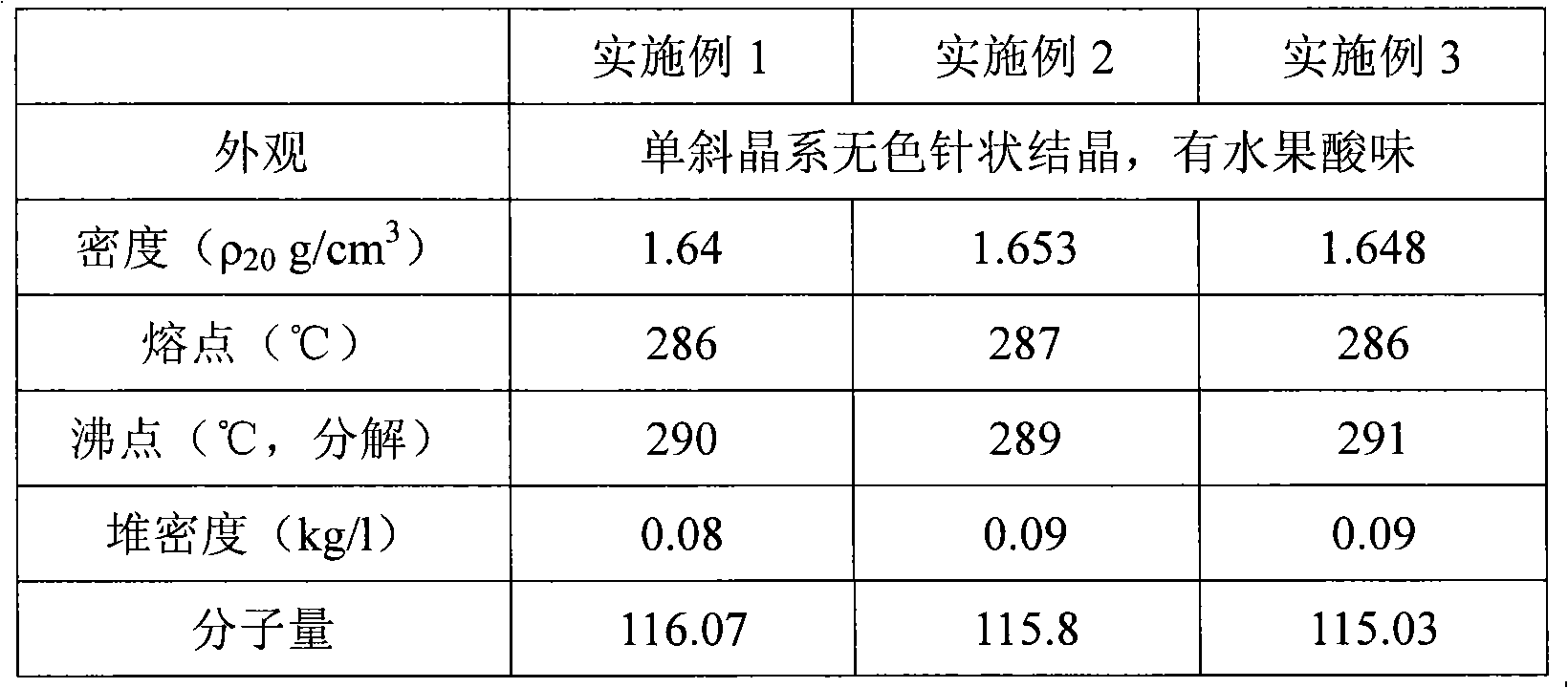

Embodiment 1

[0036] 1. Raw material pretreatment:

[0037] Corn cobs with a moisture content of ≤15% are crushed into straw fragments of 1-3 cm in size and then used for later use.

[0038] 2. Hydrolysis to produce furfural:

[0039] 1) Loading

[0040] Put the corn cob fragments into the hydrolysis kettle from the feeding port of the hydrolysis kettle, and then add dilute H 2 SO 4 Solution, mixed evenly, wherein: the inner wall of the hydrolysis kettle is sprayed with enamel anti-corrosion materials, and the pressure resistance of the hydrolysis kettle is ≥1Mpa; dilute H 2 SO 4 The mass percentage concentration of solution is 10%; Corncob broken section and dilute H 2 SO 4 The proportioning by weight of solution is 1: 3, and the broken section of corn cob and dilute H in the hydrolysis kettle 2 SO 4 The mixed volume of the solution is 70% of the volume of the hydrolysis tank;

[0041] 2) acid hydrolysis

[0042] Close the feed port cover of the hydrolysis kettle, open the exhaus...

Embodiment 2

[0059] 1. Raw material pretreatment:

[0060] The sunflower shells with a moisture content of ≤15% are crushed into 1-3 cm sunflower shell fragments for later use.

[0061] 2. Hydrolysis to produce furfural:

[0062] 1) Loading

[0063] Put the sunflower shell fragments into the hydrolysis kettle from the feeding port of the hydrolysis kettle, and then add dilute H 2 SO 4 Solution, in which: the inner wall of the hydrolysis kettle is sprayed with enamel anti-corrosion materials, and the pressure resistance of the hydrolysis kettle is ≥1Mpa; dilute H 2 SO 4 The mass percentage concentration of solution is 8%; Sunflower shell fragment and dilute H 2 SO 4 The proportioning by weight of solution is 1: 4, and the broken section of sunflower shell and dilute H in the hydrolysis kettle 2 SO 4 The mixed volume of the solution is 60% of the volume of the hydrolysis tank;

[0064] 2) acid hydrolysis

[0065]Close the feed port cover of the hydrolysis kettle, open the exhaust v...

Embodiment 3

[0082] 1. Raw material pretreatment:

[0083] Sorghum stalks with a moisture content of ≤15% are crushed into straw fragments of 1-3 cm for later use.

[0084] 2. Hydrolysis to produce furfural:

[0085] 1) Loading

[0086] Put the straw fragments into the hydrolysis kettle from the feeding port, and then add the dilute H 2 SO 4 Solution, in which: the inner wall of the hydrolysis kettle is sprayed with enamel anti-corrosion materials, and the pressure resistance of the hydrolysis kettle is ≥1Mpa; dilute H 2 SO 4 The mass percent concentration of the solution is 12%; the straw fragments and dilute H 2 SO 4 The weight ratio of the solution is 1: 3.5, and the straw fragments and dilute H in the hydrolysis kettle 2 SO 4 The mixed volume of the solution is 65% of the volume of the hydrolysis tank;

[0087] 2) acid hydrolysis

[0088] Close the feed port cover of the hydrolysis kettle, open the exhaust valve on the upper part of the hydrolysis kettle, and turn on the coil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com