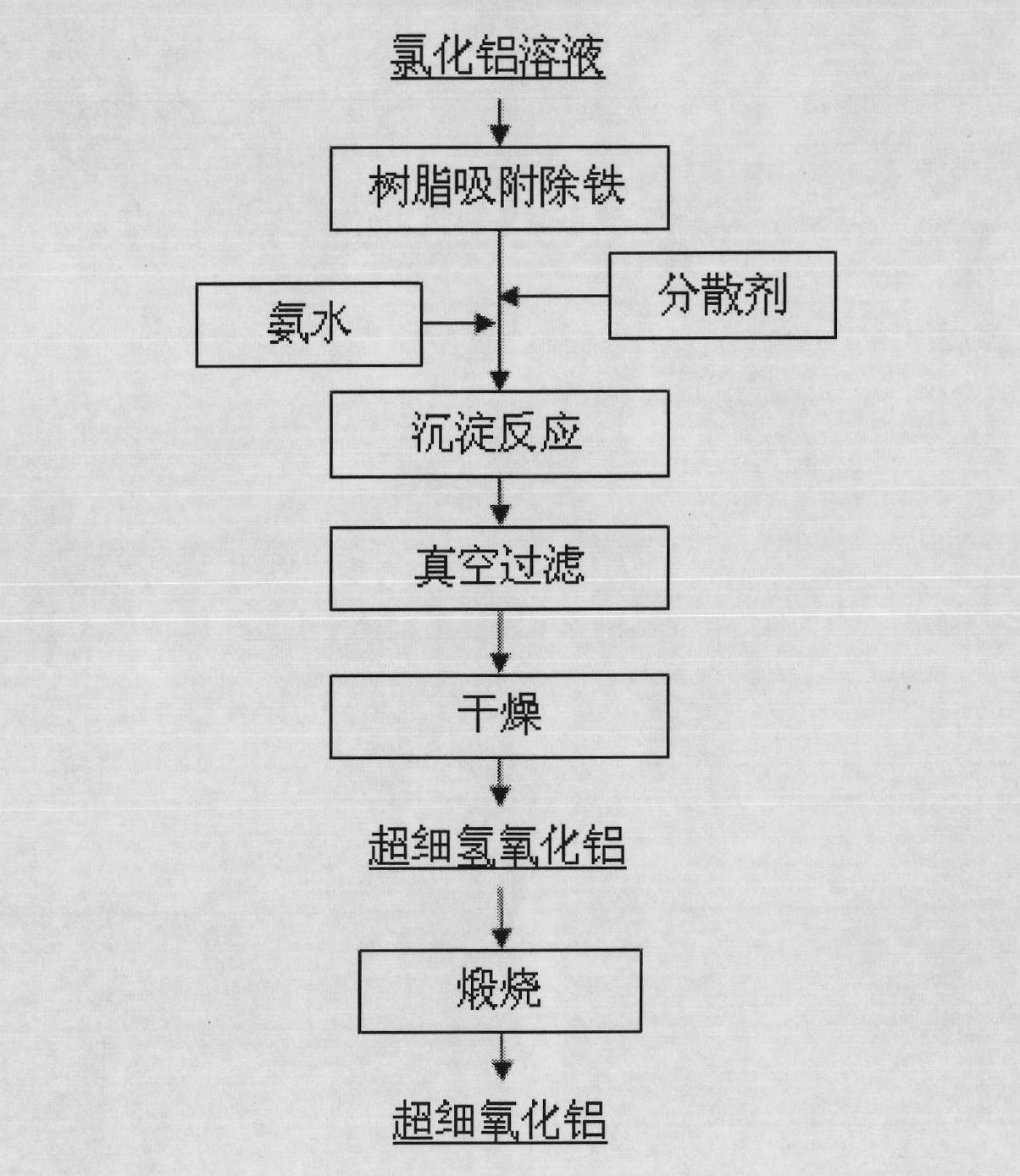

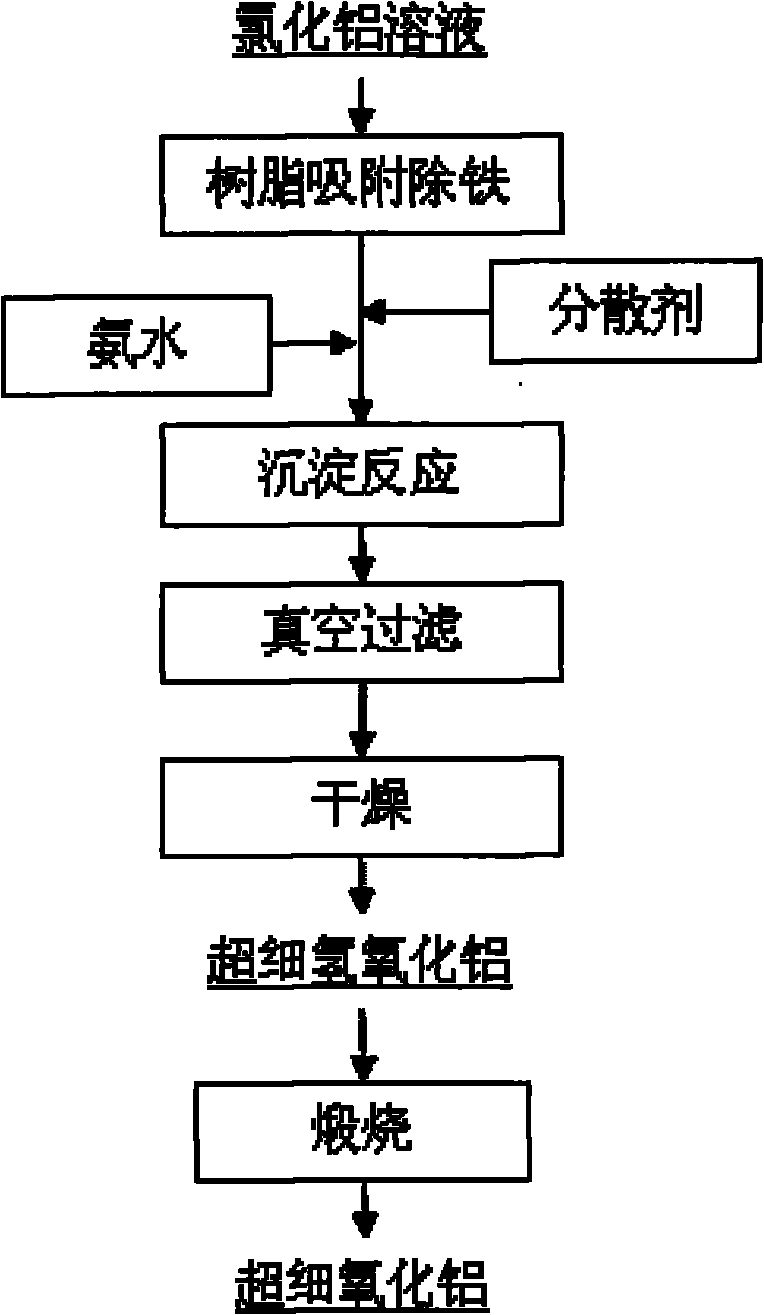

Method for producing superfine aluminum hydroxide and aluminum oxide by using solution of aluminum chloride

A technology of ultra-fine aluminum hydroxide and aluminum chloride, which is applied in the field of production of ultra-fine aluminum hydroxide and alumina with low iron content, can solve the problems of high raw material requirements, complex production process, production process and raw material limitation, and achieve technological The effect of short process, guaranteed product purity and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] (1) Using AlCl 3 Concentration is 2.3mol / L, and the aluminum chloride solution that contains iron (calculated as iron oxide) 1.9g / L is raw material, adopts the mode of single column to adsorb and remove iron with D001 (Anhui Wandong Chemical Factory) resin at room temperature, The flow rate of aluminum chloride solution is 2 times of resin volume / hour. It was determined that the iron content (calculated as iron oxide) in the treated refined solution was reduced to 0.24 mg / L.

[0025] (2) Add 5 wt% of PEG4000 as a dispersant to the aluminum chloride refined solution, and the amount of the dispersant is 5% of the volume of the refined solution to obtain a dispersion.

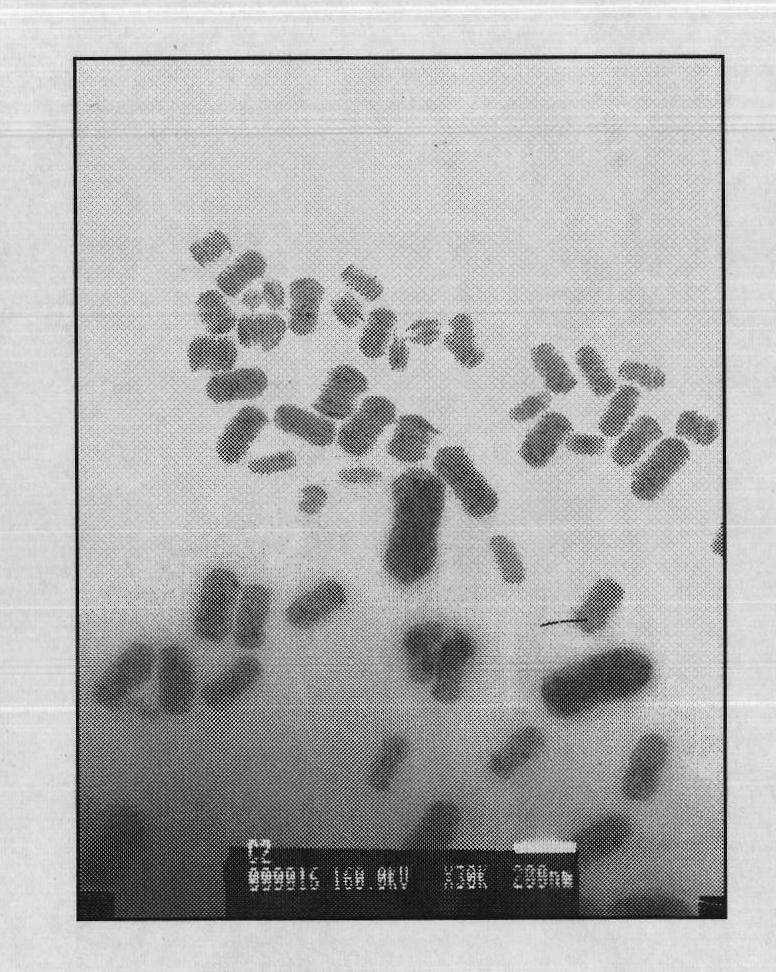

[0026] (3) Gradually add ammonia water with a concentration of 1 mol / L to the dispersion liquid under stirring until the pH value of the solution is 8 to obtain an aluminum hydroxide slurry. Vacuum filter the aluminum hydroxide slurry, wash with water 4 times and alcohol 2 times, and dry in a vacuum oven ...

Embodiment 2

[0029] Except step (1), other other operating process conditions are all identical with embodiment 1. Process condition in step (1) is adjusted to:

[0030] (1) Using AlCl 3 Concentration is 2.3mol / L, and the aluminum chloride solution that contains iron (calculated as iron oxide) 1.9g / L is raw material, with the resin column that JK008 (Anhui Wandong chemical plant) resin is housed at room temperature, adopts double-column string Iron removal is carried out in a continuous manner, and the flow rate of the aluminum chloride solution is 4 times the resin volume / hour. After treatment, the iron content (calculated as iron oxide) in the refined solution was reduced to 0.21mg / L.

[0031] It has been determined that the particle size of ultra-fine aluminum hydroxide is ~0.2 microns, and the specific surface area is 211m 2 / g, the iron oxide content is 0.010wt%.

Embodiment 3

[0033] Change the raw material of aluminum chloride solution to AlCl 3 Aluminum chloride solution with a concentration of 1.7mol / L and an iron content (calculated as iron oxide) of 2.6g / L. All operating process conditions are identical with embodiment 1. Ultrafine aluminum hydroxide product is obtained after resin adsorption, neutralization, filtration, washing and drying.

[0034] It has been determined that the particle size of ultra-fine aluminum hydroxide is ~0.2 microns, and the specific surface area is 217m 2 / g, the iron oxide content is 0.015wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com