Method absorbing lead ions in sewage with tremolite amianthine

A tremolite, the technology of tremolite, applied in the direction of adsorption water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., to achieve the advantages of convenient operation, simple preparation process and high adsorption rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

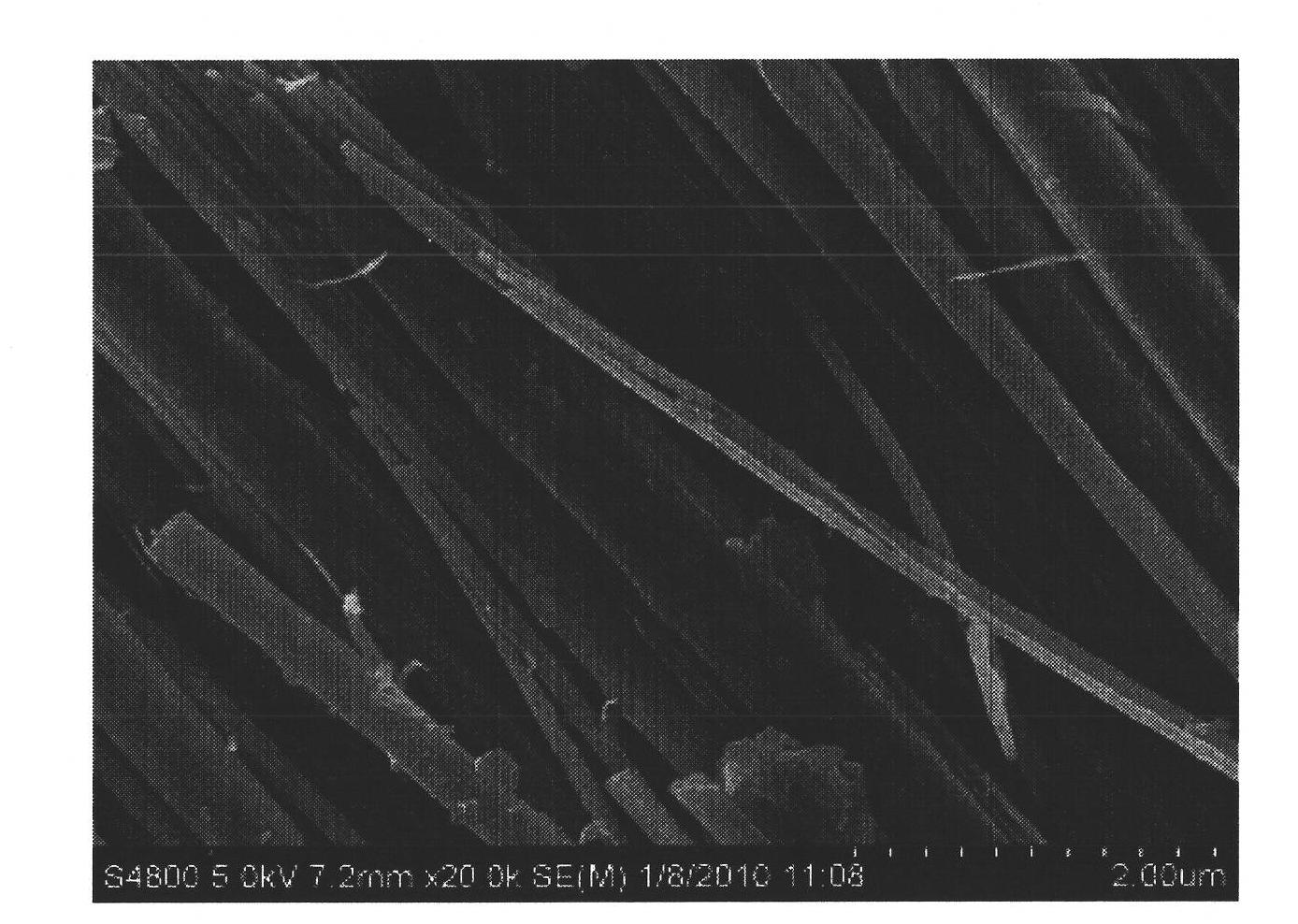

[0028] Sorbent preparation

[0029] Take a certain amount of different tremolite wool, natural zeolite, sepiolite wool, bentonite, kaolin and other adsorbents, and roast them in a DHG-9070A electric blast drying oven at a temperature of 100-110°C for 3-4 hours; After grinding, sieve under 80-100 mesh standard sieve to obtain different adsorbent powders.

[0030] Preparation of tremolite wool adsorbent

[0031] Prepare 100ml of 0.05-0.10mol / L ferric chloride solution, mix 2-3g of tremolite velvet with 100ml ferric chloride solution of various concentrations, and shake with an oscillator at 300 times / min for 20-24 hours at room temperature Suction. Wash the filter cake with distilled water for 2-3 times, put the filter cake in a blast drying oven at 140-150°C for 1-2 hours, crush and grind the filter cake, and sieve it under 80-100 mesh to obtain tremolite Lint absorbent.

Embodiment 1

[0032] Embodiment 1: Screening of different adsorbents

[0033] Take 0.2g of different tremolite wool, natural zeolite, sepiolite wool, bentonite, kaolin and other adsorbents, mix them with 100ml of 50mg / L lead nitrate solution (simulating the concentration of lead ions in wastewater), and mix them at 20°C Shake in a constant temperature oscillator in a water bath at low temperature for 1 hour. After the solution is centrifuged, take the supernatant and put it into a small test tube, and analyze and detect it with a Shimadzu AA-6200 atomic spectrophotometer.

[0034] Table 2 Screening of the best adsorbent

[0035] Adsorbent Removal rate (%) Adsorption capacity (mg / g)

[0036] Natural zeolite 96.62 24.13

[0037] Meerschaum 95.17 23.77

[0038] Bentonite 96.44 24.09

[0039] Kaolin 96.07 24.00

[0040] Tremolite 99.77 25.00

[0041] Experimental results: tremolite wool adsorbent is used to adsorb heavy metal Pb in water, the treated water can meet the discharge standard,...

Embodiment 2

[0042] Embodiment 2: Determination of the optimal amount of adsorbent

[0043] Take 0.1g, 0.2g, 0.5g, 1.0, 1.5g, 2.0g of tremolite wool adsorbent, mix it with 100ml of lead nitrate solution (simulating the concentration of lead ions in wastewater) with a concentration of 50mg / L, and mix it at 20°C Shake in a constant temperature oscillator in a water bath for 1 hour. After the reaction, the solution is centrifuged, and the supernatant is put into a small test tube, and analyzed and detected by a Shimadzu AA-6200 atomic spectrophotometer.

[0044] Table 3 Screening of optimal adsorbent dosage

[0045] Adsorbent dosage (g) Removal rate (%)

[0046] 0.1 99.32

[0047] 0.2 99.77

[0048] 0.5 100.00

[0049] 1.0 100.00

[0050] 1.5 100.00

[0051] 2.0 100.00

[0052] Experimental results: tremolite wool adsorbent is used to adsorb and treat heavy metal Pb in low-concentration wastewater, and the optimal dosage for 100ml treatment volume is 0.2g-0.5g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com