Composite veneer

A veneer and cross-section technology, applied in the field of composite veneer, can solve the problems of short heat conduction path, low heat conduction efficiency, complicated manufacturing process, etc., and achieve the effect of short heat conduction path, high heat conduction efficiency and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

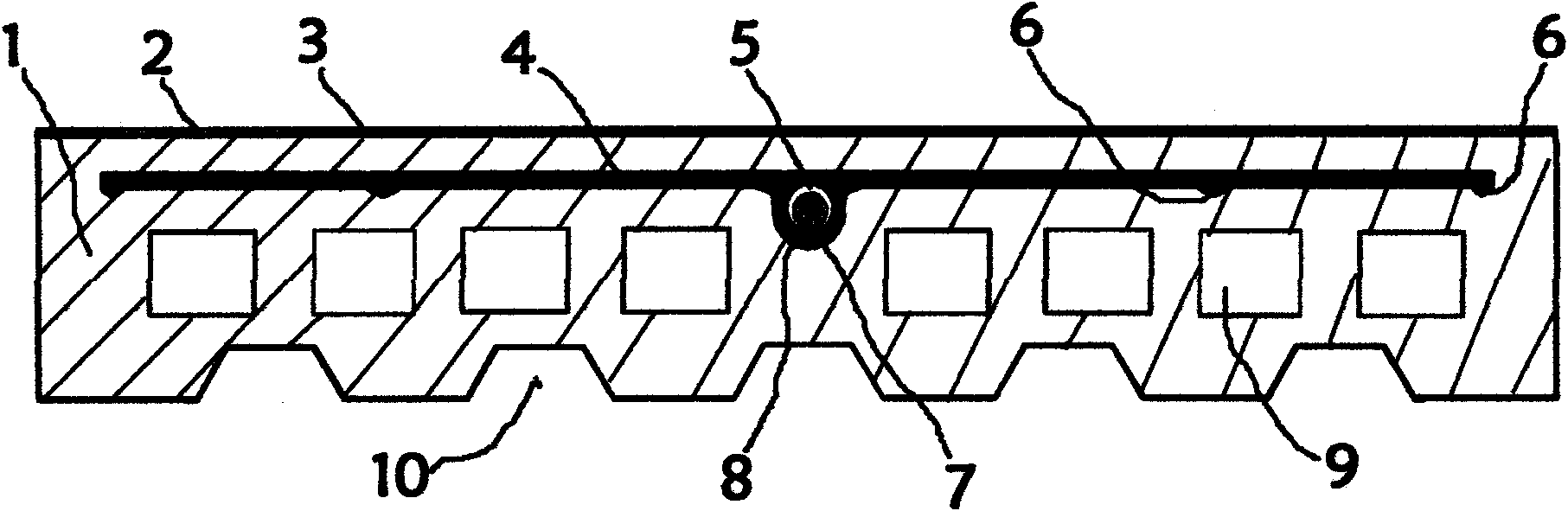

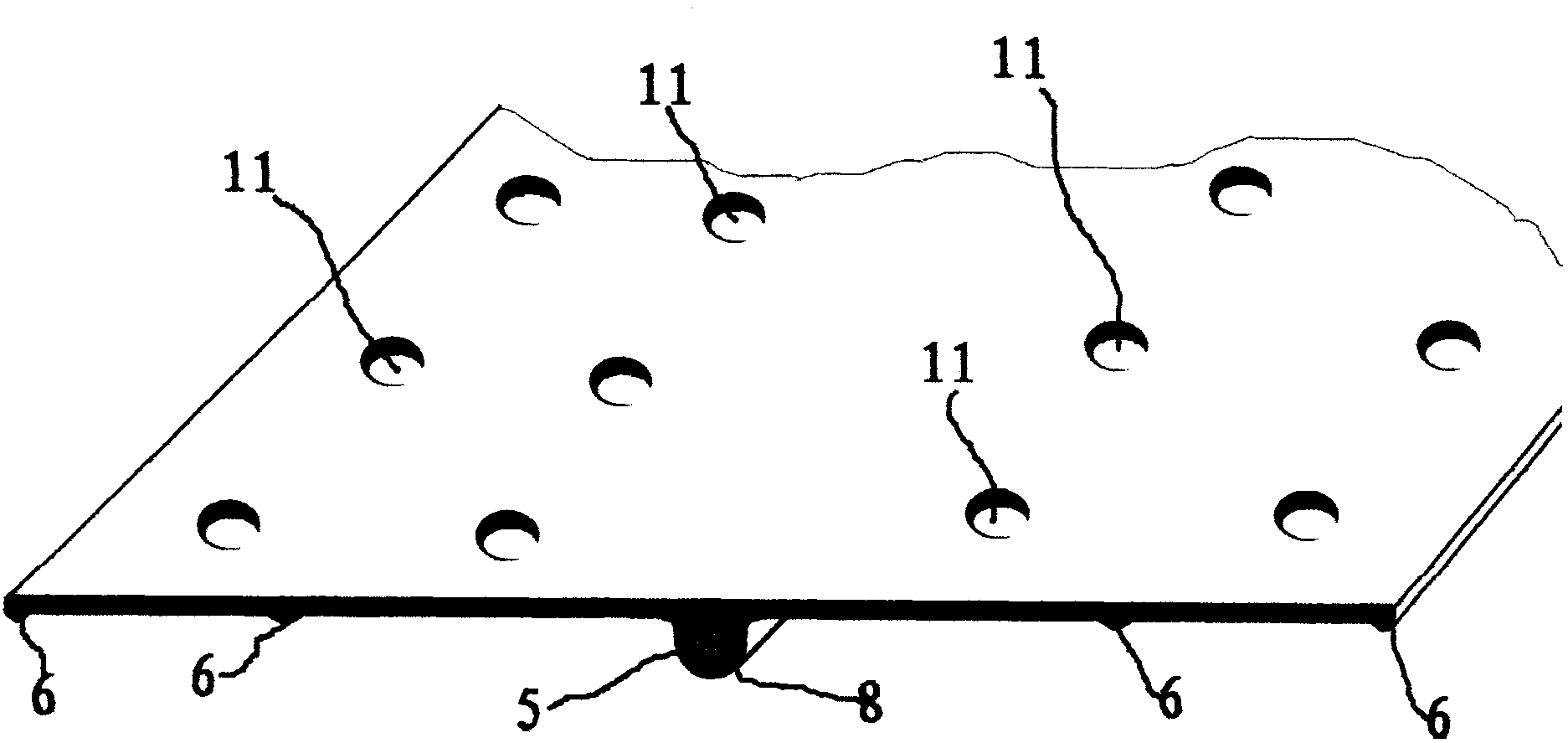

[0022] Embodiment 1: as figure 1 , image 3 and Figure 4 As shown, the surface of the composite veneer body 1 is provided with a surface decoration layer 2 and a paint wear-resistant layer 3 in sequence, and a flat strip-shaped heat-conducting medium 4 is arranged inside the composite veneer body 1, such as image 3 A structural schematic diagram of a heat-conducting medium 4 is shown. In this embodiment, the heat-conducting medium 4 is an aluminum alloy profile. The inside of the longitudinal rib 8 is provided with a first through hole 5 extending along the length direction of the rib. On the lower surface of the heat transfer medium 4, two reinforcing ribs 6 are evenly arranged on the left and right sides of the longitudinal rib 8 to strengthen the The strength of the heat conduction medium 4 of the aluminum alloy profile, the upper and lower surfaces of the heat conduction medium 4 of the aluminum alloy profile are provided with a number of second through holes 11 penetr...

Embodiment 2

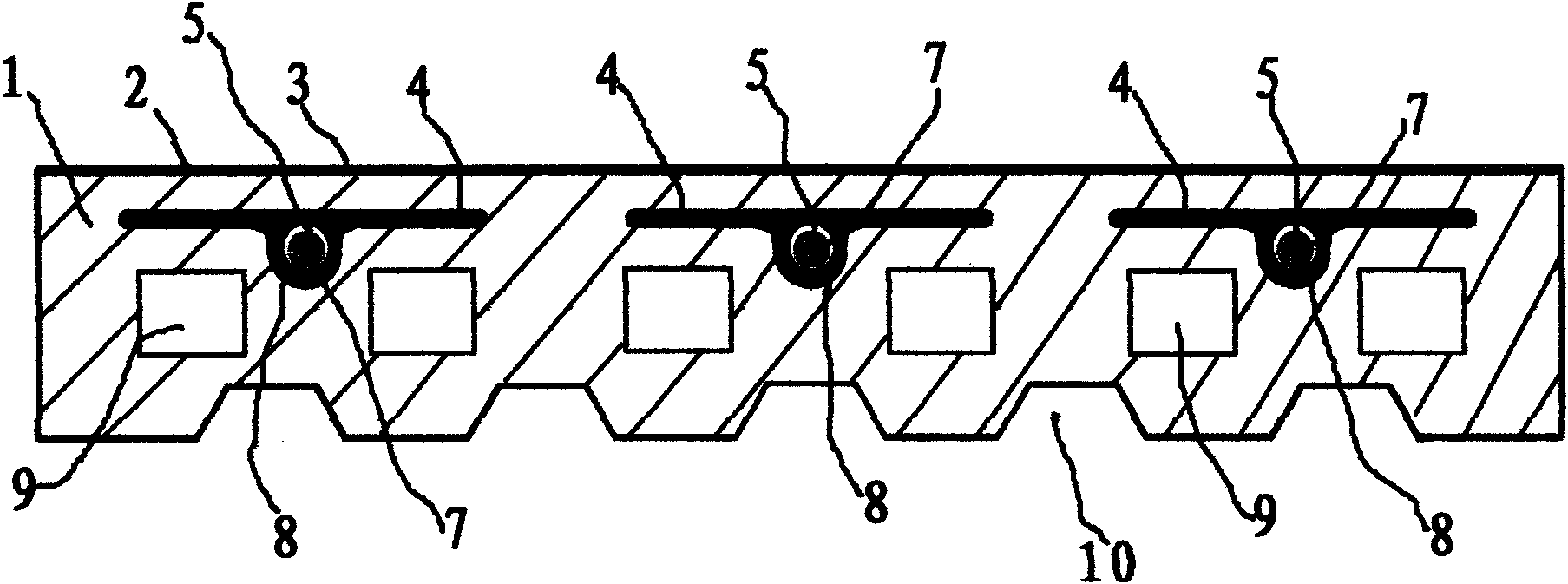

[0023] Embodiment 2: as figure 2 and Figure 4 As shown, the surface of the composite veneer body 1 is provided with a surface decoration layer 2 and a paint wear-resistant layer 3 in sequence, and three flat strip-shaped heat-conducting media 4 are arranged at equal intervals inside the composite veneer body 1 . The surface is flat without protrusions, and the middle position of the lower surface is provided with a longitudinal ridge 8 , and the inside of the longitudinal ridge 8 is provided with a first through hole 5 extending along the length direction of the ridge. The material of the composite veneer body in this embodiment is plastic-wood composite material (or called wood-plastic composite material) or stone-plastic composite material. Or the stone-plastic composite material is co-extruded through a mold, so that the heat-conducting medium 4 is tightly fixed in the main body of the veneer. The composite veneer body 1 is provided with six third through holes 9 passin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com