Fire-resistant steel material with excellent resistance to reheat embrittlement and with low-temperature toughness at welded heat-affected parts, and manufacturing method thereof

A technology of welding heat influence and low temperature toughness, applied in the field of refractory steel, can solve the problems of HAZ reheat embrittlement, unfavorable high temperature strength, and difficulty in obtaining bainite structure, etc., to achieve reheat embrittlement suppression and high yield strength , Excellent effect of low temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0147] Hereinafter, the present invention will be described in more detail by citing examples of the fire-resistant steel material of the present invention and its manufacturing method, but the present invention is of course not limited to the following examples, and can be appropriately increased within the scope consistent with the purpose described before and after. Modified implementations are included within the technical scope of the present invention.

[0148] [Production of refractory steel]

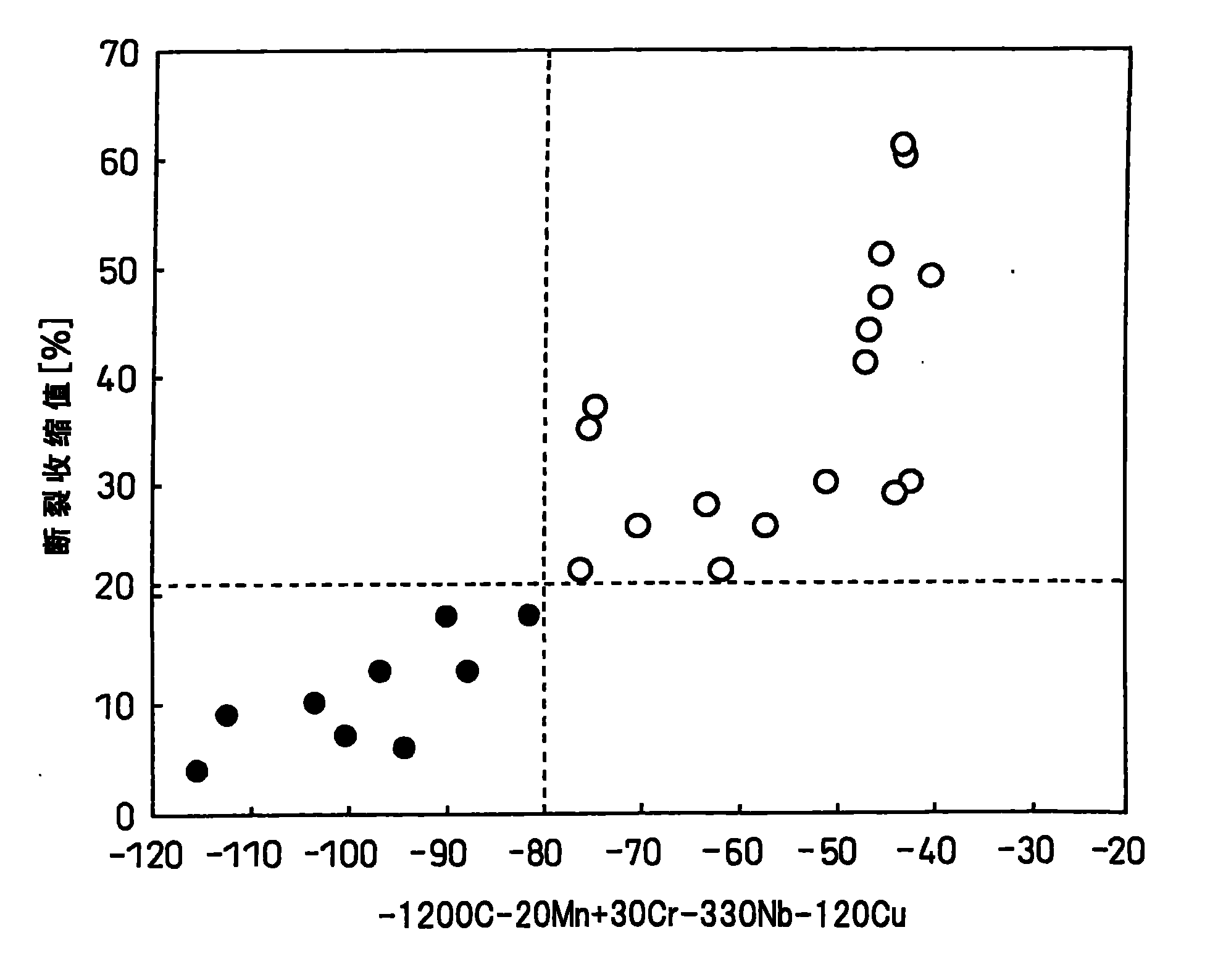

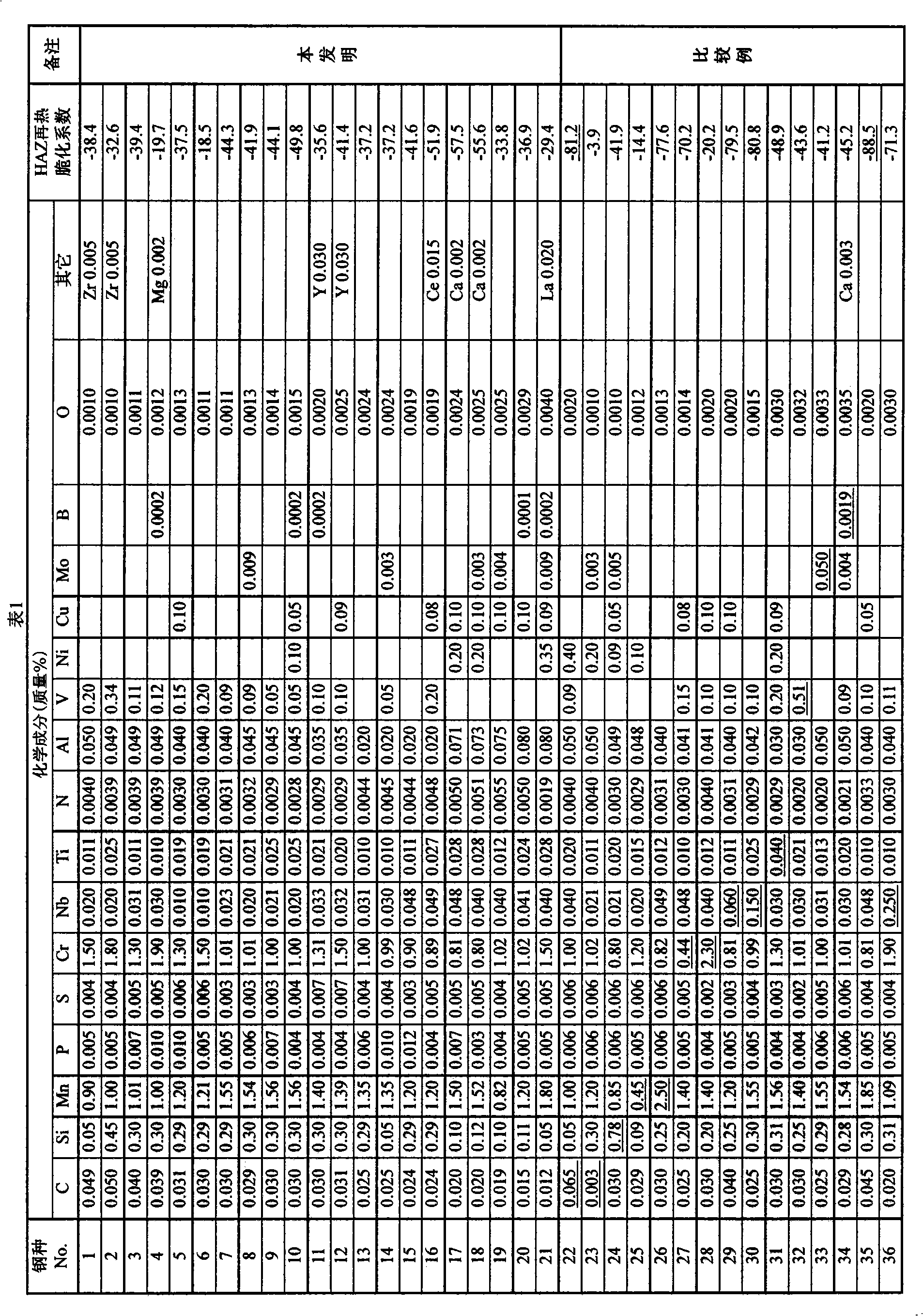

[0149] Slabs having chemical compositions shown in Table 1 below were produced by continuous casting by controlling deoxidation, desulfurization, and chemical composition of molten steel in the steelmaking process. Then, according to the production conditions shown in the following Table 2, the slab is reheated and hot-worked to form a predetermined plate thickness, and then heat-treated under various conditions to produce the refractory products of the examples of the present in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield stress | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com