Electric power recharging method of motor

A technology of electric motor and electric power, which is applied in the field of energy recovery using brushless permanent magnet motor coil short circuit, which can solve problems such as unsmoothness, poor power generation effect, and unsmooth ride feeling, so as to achieve the best power generation effect and avoid the feeling of unsmoothness and dangerous effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

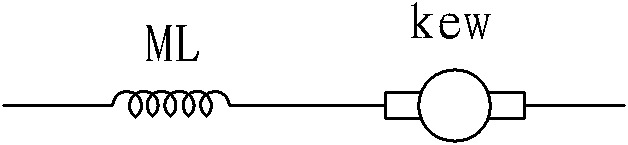

[0029] Please refer to figure 1 , is a structural schematic representation of the operating principle used in the present invention; this schematic circuit diagram is a boost converter (boost converter) circuit of a DC converter (DC to DC), including a power storage device B, an inductor L, and a switch Q, a diode D, a capacitor C, a load R1oad and an output voltage Vo.

[0030] In this circuit, the inductance L is used to temporarily store the energy converted between electric energy and magnetic field energy. When the switch Q is turned on, the voltage Vb of the power storage device B charges the inductance L, and the inductance L converts the electric energy into Magnetic fields can be stored.

[0031] At this time, the terminal volt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com