Ultra-low temperature constant temperature grabbing bar device

A technology of ultra-low temperature and constant temperature, which is applied in the direction of applying stable tension/pressure to test the strength of materials, and can solve the problems of evaluating performance of testing devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, how the present invention is implemented is described further:

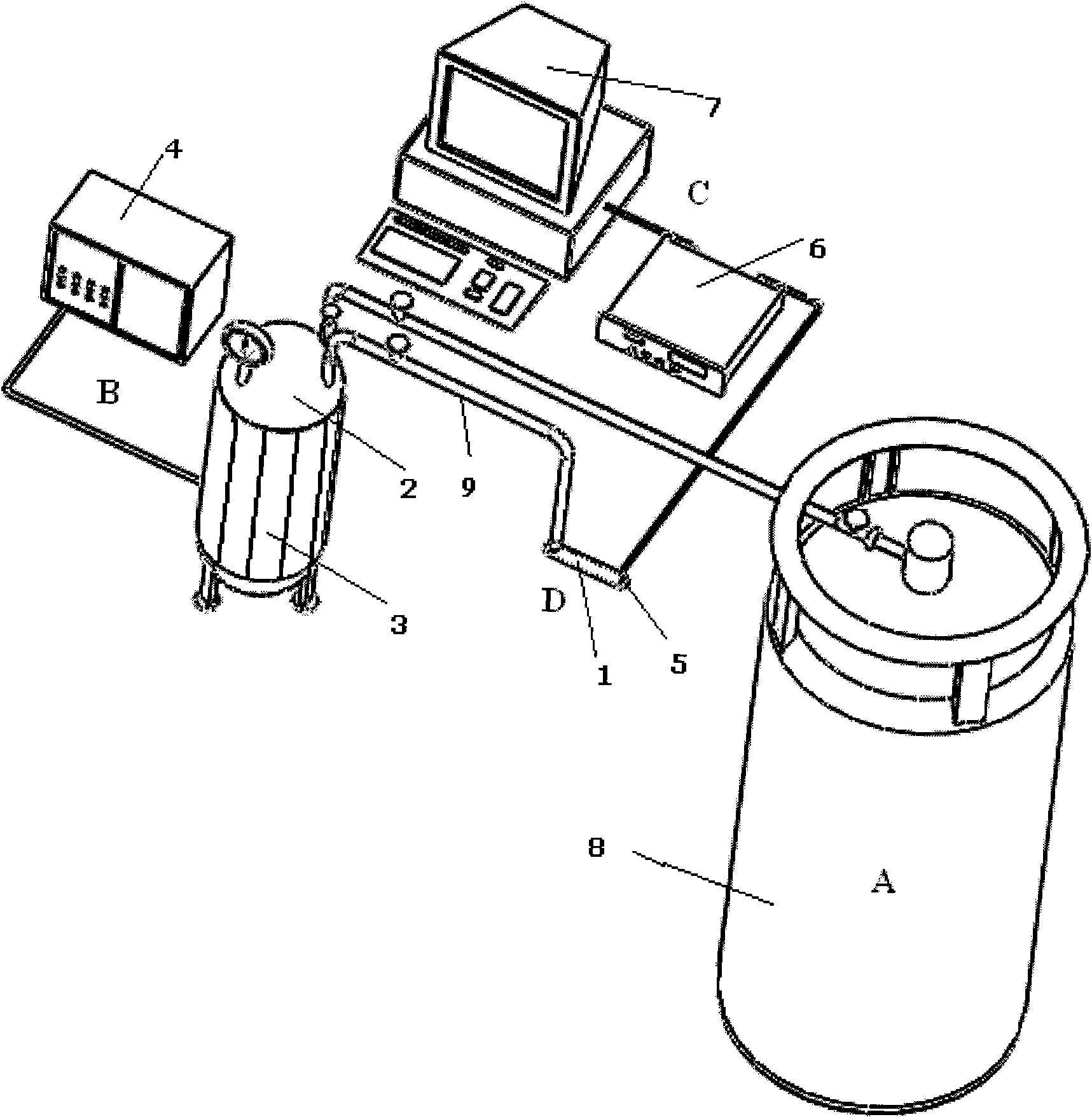

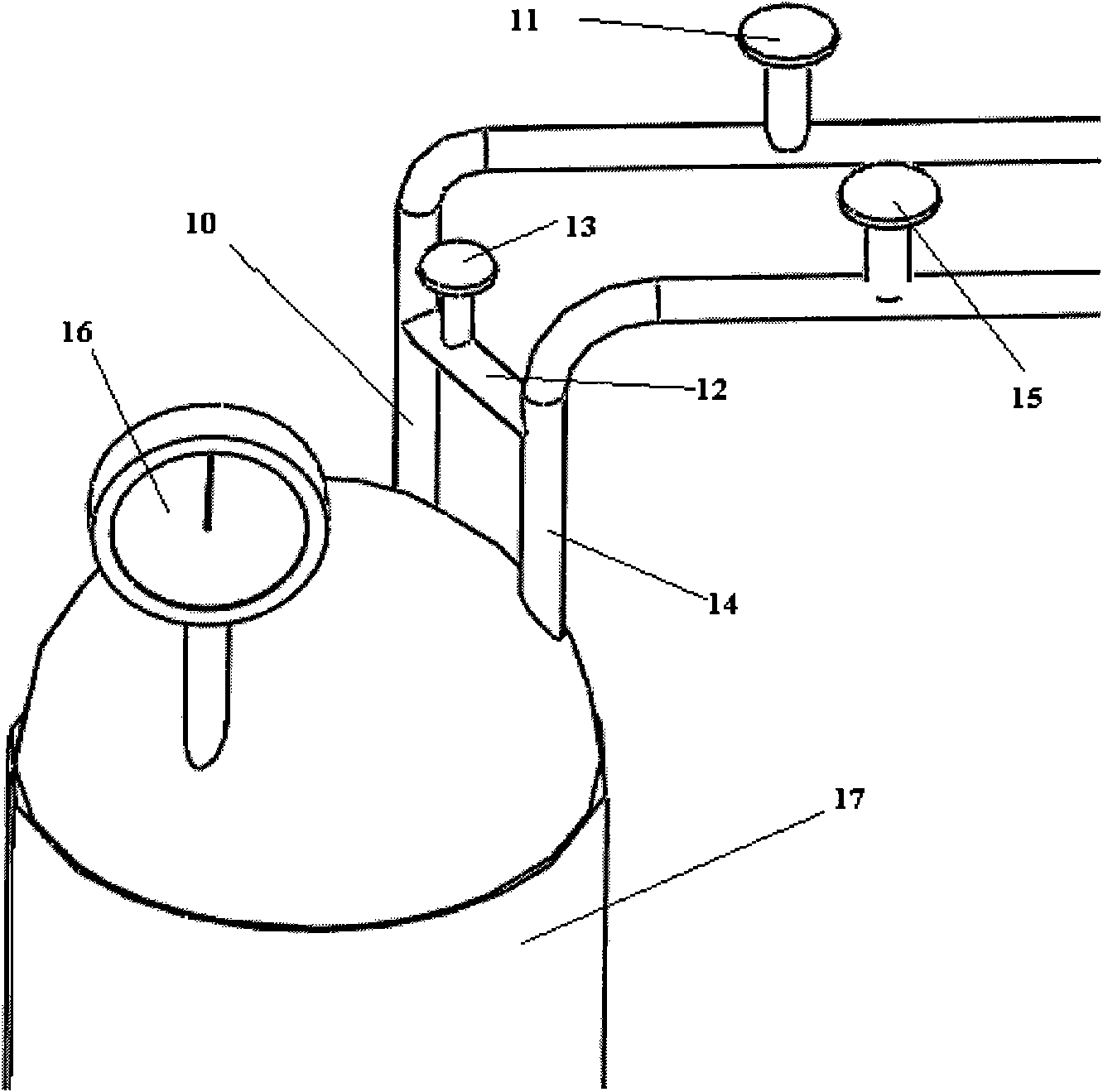

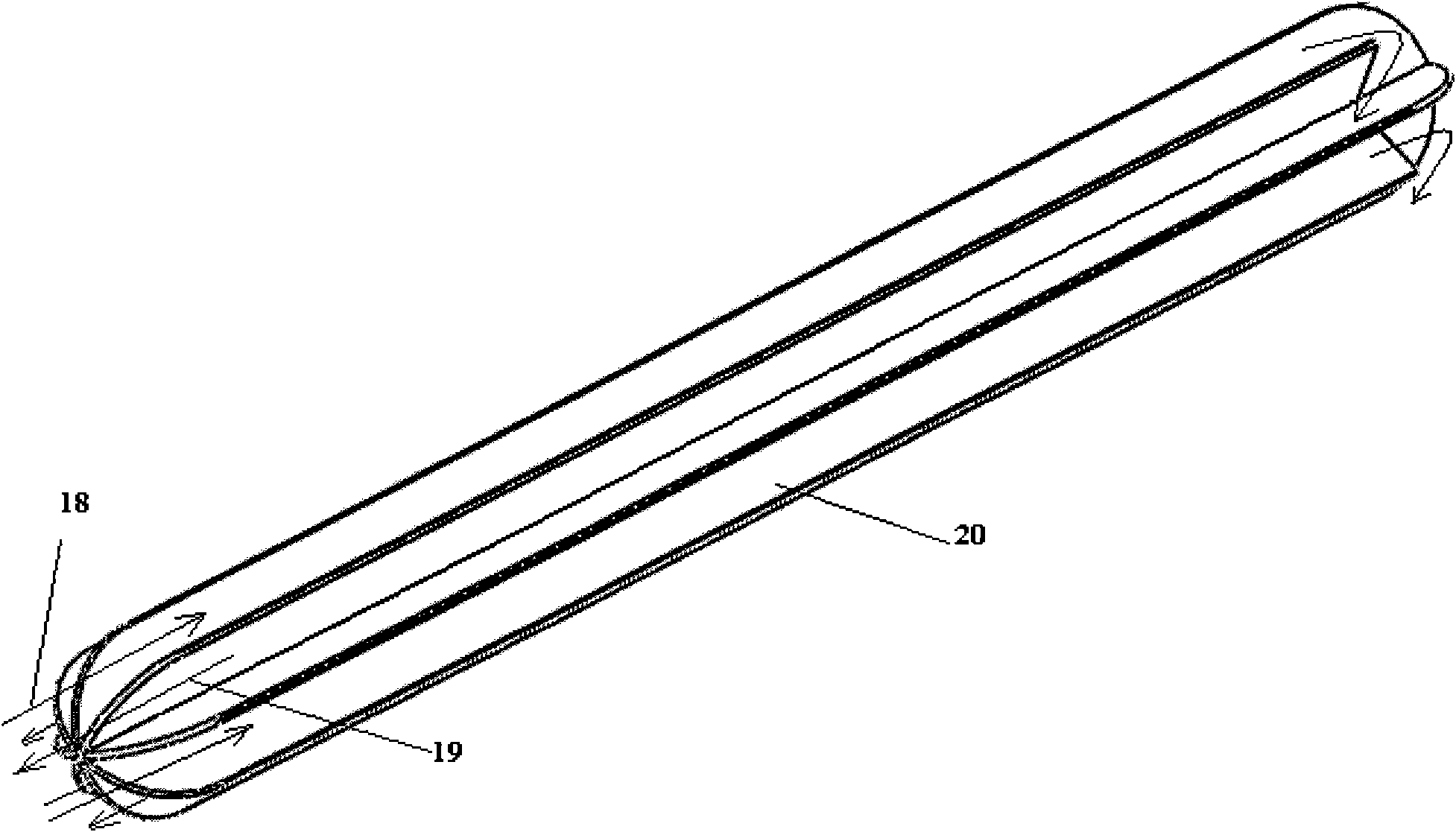

[0026] The present invention is an ultra-low temperature constant temperature grip rod device, such as figure 1 As shown, the device is mainly divided into 4 parts: refrigeration system A, constant temperature system B, temperature measurement system C and grasping system D. Refrigeration system A is a pressurized Dewar bottle 8, which provides ultra-low temperature through liquid nitrogen in the bottle. The main function of the constant temperature system B is to vaporize liquid nitrogen to obtain low-temperature nitrogen, and control the temperature of nitrogen through the liquid nitrogen valve and the temperature of the heating plate to ensure that the temperature of low-temperature nitrogen is constant and meets the experimental requirements. The main function of the temperature measurement system C is to collect, monitor and record the temperature value...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com