Method for preparing easily mixed high filling clay/rubber nano composite material

A rubber nano-composite material technology is applied in the field of preparing clay/rubber nano-composite materials with easy mixing, high filling and high dispersion, and can solve the problems of difficult processing, long drying time, low drying and drying process efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Add 500 g of commercially available natural sodium-based bentonite into 10 L of deionized water, stir for 5 hours at a rotating speed of 800 r / min, and after standing for 24 hours, a clay / water suspension with a solid content of 2.0% is obtained; take 2000 g of clay / water Suspension, mix 15min with 500g styrene-butadiene rubber emulsion (SBR1502, solid content is 20%) under the rotating speed of 480r / min; The mixed solution is joined under stirring, and mass concentration is flocculation in the dilute sulfuric acid solution of 1%; The 5 μm-50 μm micelles of clay / styrene-butadiene rubber obtained by flocculation are repeatedly washed to neutrality; the water suspension of the flocculation gels is transferred to a spray drying device for spray drying treatment. The drying medium is simple hot air at 200 ° C. The outlet temperature is 100°C. The dried samples were collected to obtain a clay / styrene-butadiene rubber compound with a clay content of 40 phr.

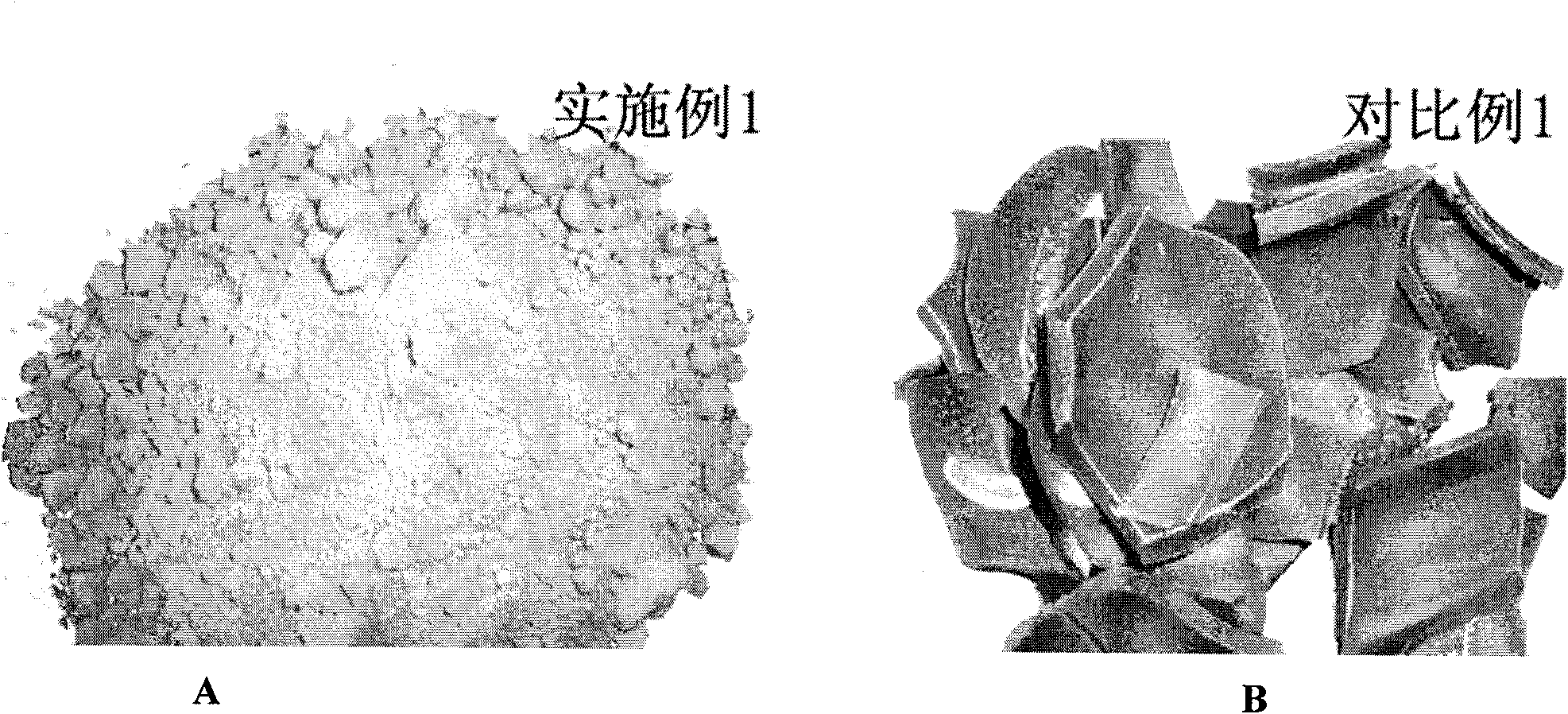

[0024] The appe...

Embodiment 2

[0026] Add 500 g of commercially available natural sodium-based bentonite into 10 L of deionized water, stir for 5 hours at a speed of 800 r / min, and after standing for 72 hours, a clay / water suspension with a solid content of 2.0% is obtained; take 2000 g of clay / water Suspension, mix 15min with 217.4g nitrile rubber emulsion (N240S, solid content is 46%) under the rotating speed of 480r / min; The mixed solution is joined under stirring, and mass concentration is flocculation in the calcium chloride solution of 1% ;The 15μm-80μm micelles of clay / nitrile rubber obtained by flocculation are left standing repeatedly, washed with water until neutral; the water suspension of the flocculation gels is transferred to a spray drying device for spray drying treatment, and the drying medium It is pure hot air at 350°C, and the outlet temperature is 120°C. The dried samples were collected to obtain a clay / nitrile rubber mixed compound with a clay content of 40 phr.

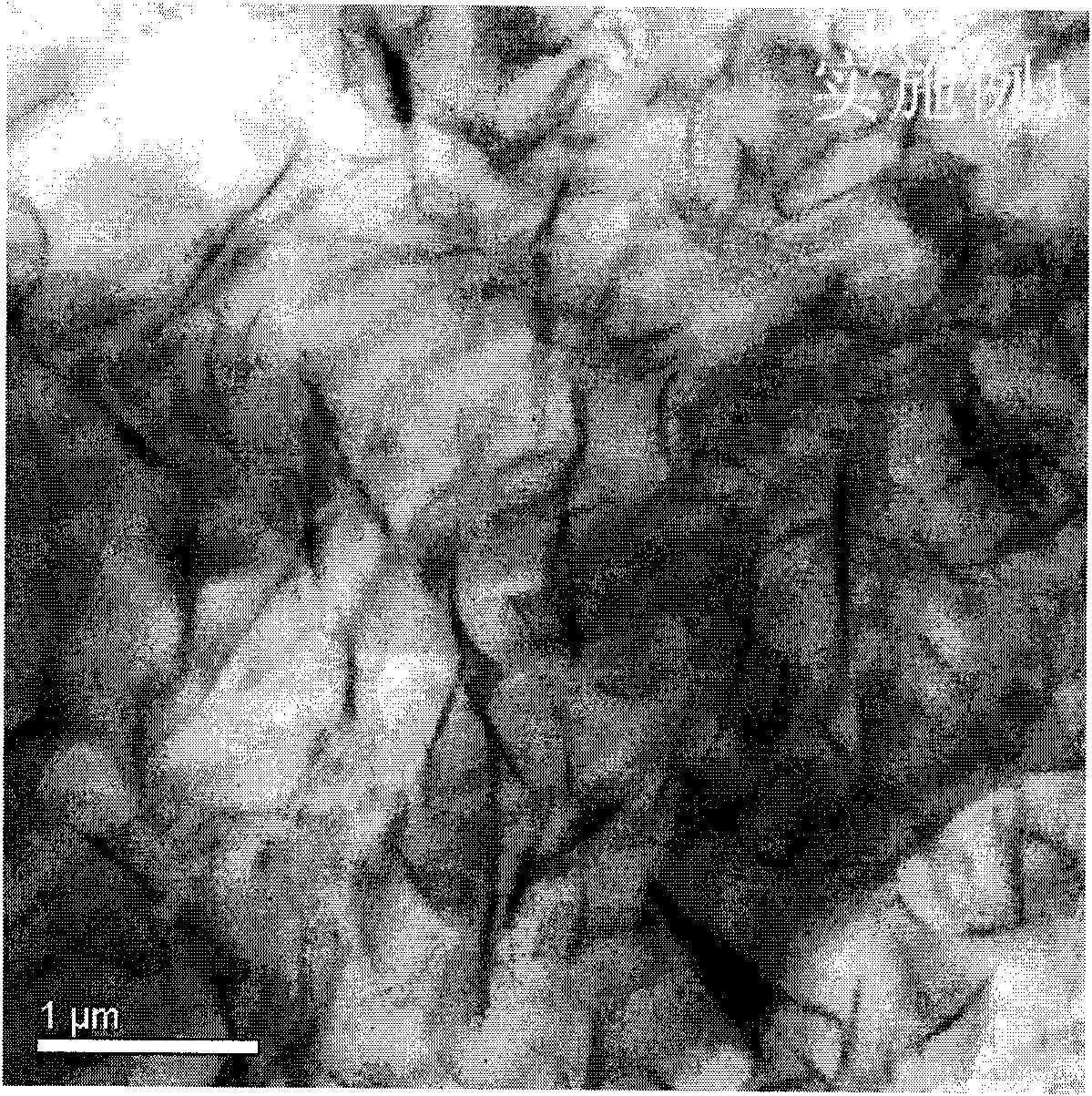

[0027] The transmiss...

Embodiment 3

[0029] Add 500 g of commercially available natural sodium-based bentonite into 10 L of deionized water, stir for 5 hours at a speed of 800 r / min, and after standing for 72 hours, a clay / water suspension with a solid content of 2.0% is obtained; take 2000 g of clay / water Suspension, mixes 15min with 158.7g natural rubber emulsion (solid content is 63%) under the rotating speed of 480r / min; The mixed solution is joined under stirring, and mass concentration is flocculation in the aluminum chloride solution of 1%; Flocculation The 25μm-100μm micelles of the obtained clay / natural rubber were left standing repeatedly, washed with water until neutral; the water suspension of the flocculated gels was transferred to a spray drying device for spray drying treatment, and the drying medium was 100°C heat Air, using microwaves to heat atomized droplets to replenish energy, the outlet temperature is 80°C. The dried samples were collected to obtain a clay / natural rubber compound with a clay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com