Silica-based condenser microphone and production method thereof

A condenser microphone and a technology of a manufacturing method, applied to electrical components, electrostatic transducers, microphones, sensors, etc., can solve the problems of small insulation resistance between the diaphragm and the backplane, improve electrical performance, avoid contact resistance, and solve leakage problems Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

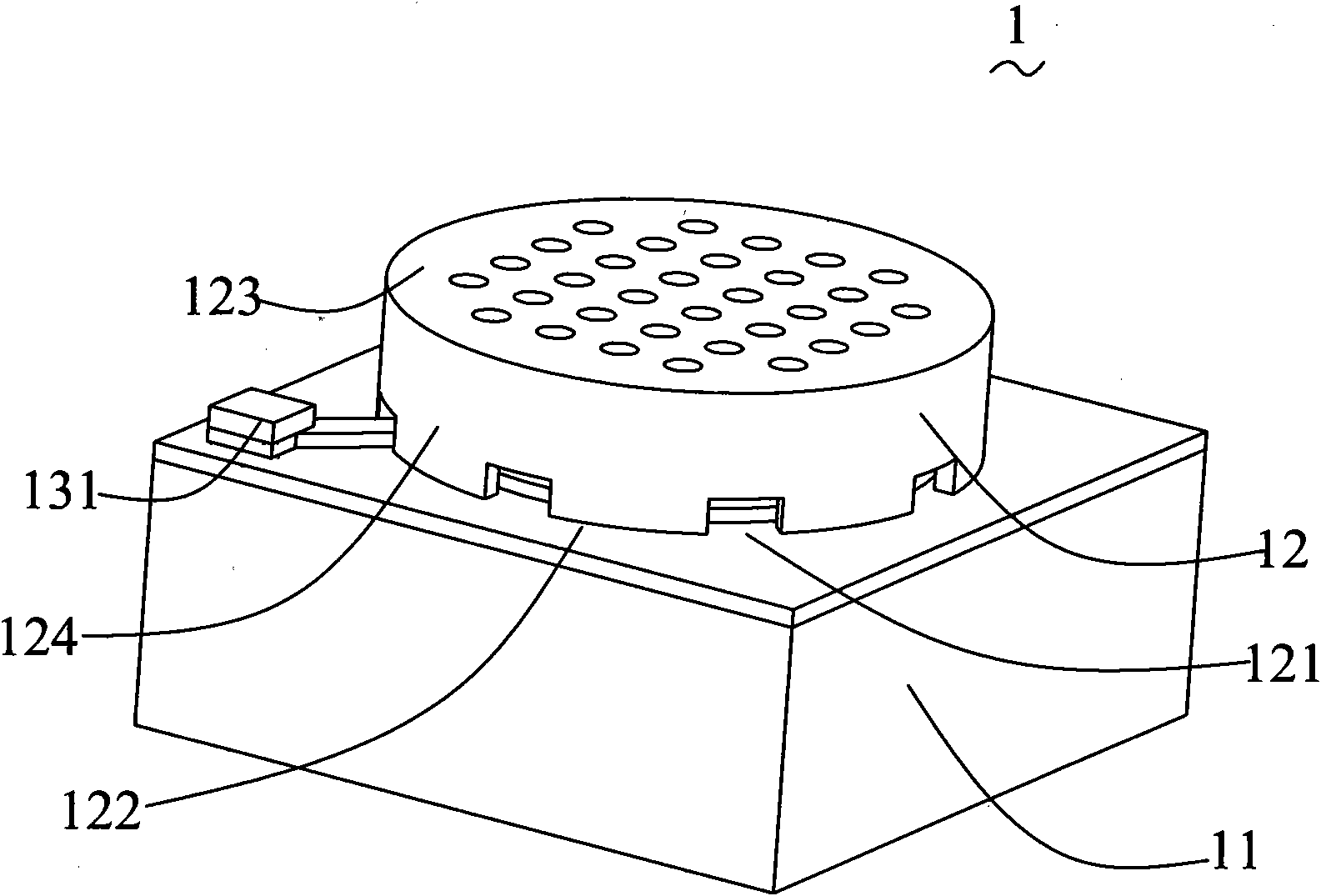

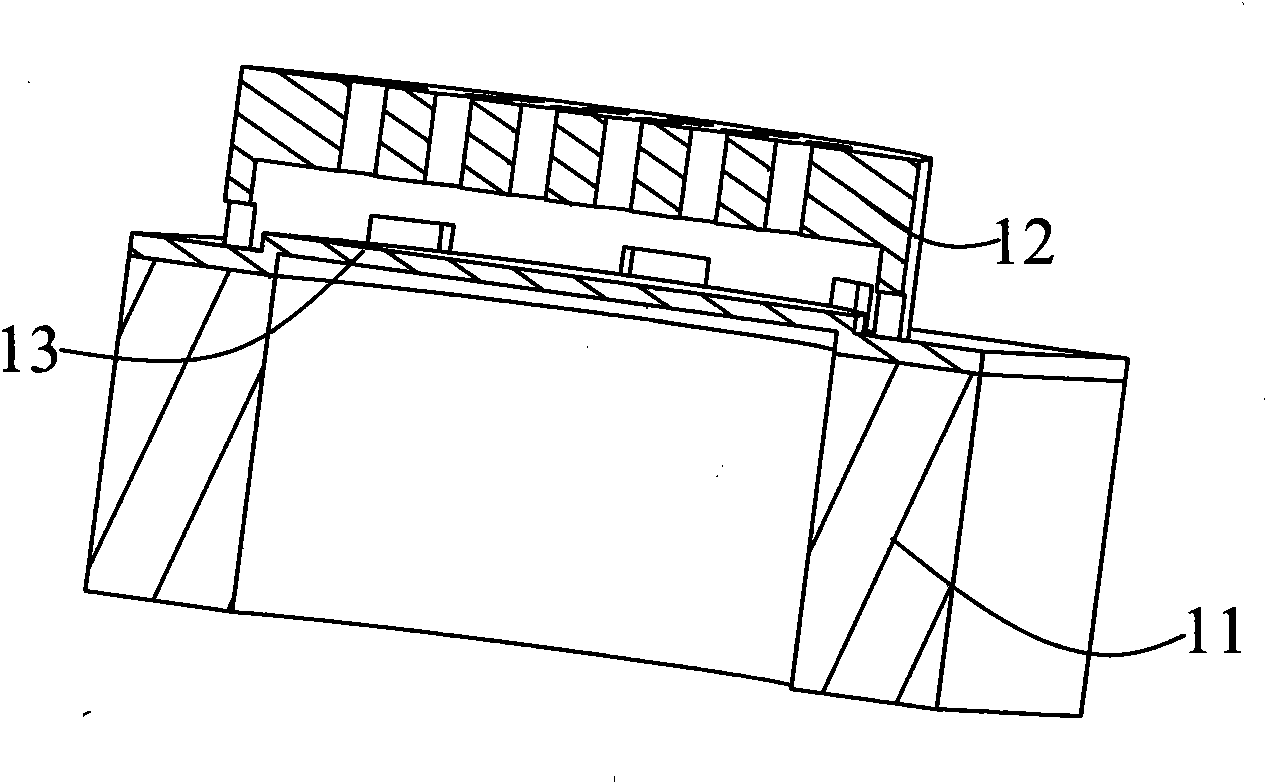

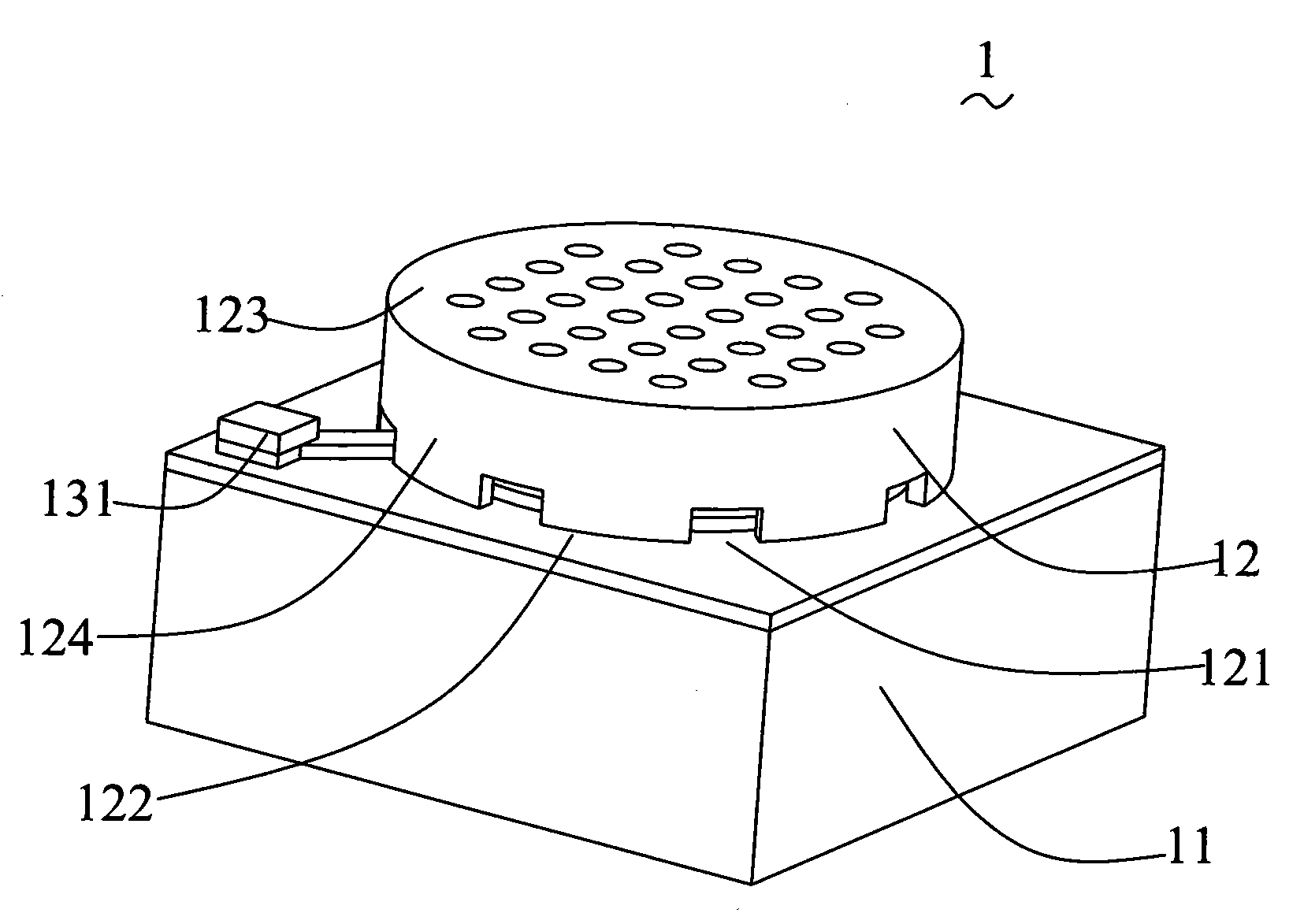

[0022] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0023] The silicon condenser microphone 1 provided by the present invention is mainly used in electronic devices such as mobile phones for receiving sound.

[0024] The manufacture method of the silicon-based condenser microphone provided by the invention, the method comprises the following steps:

[0025] Step A: providing a silicon substrate, and depositing an etching stopper layer on the silicon substrate;

[0026] Step B: depositing a stress balance layer on the etch stop layer;

[0027] Step C: depositing a diaphragm on the stress balance layer;

[0028] Step D: depositing a sacrificial layer on the silicon substrate, and engraving a latent image;

[0029] Step E: depositing the backplane;

[0030] Step F: Doping the backplane to make it a conductor;

[0031] Step G: etching the backplane;

[0032] Step H: Deposit electrodes and make ohmic co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com